Procedure

Proceed as follows to attach an output element (for example, a coupling) to the motor:

1. Select a coupling.

Use a exible coupling with high torsional rigidity specically designed for servo motors,

which can transfer the motor torque to the mechanics and compensate radial, axial, and

angular misalignments.

2. Install the coupling.

Do not strike the shaft when installing a coupling. Ensure that the radial and axial forces are

smaller than the allowable maximum values specied in Section "Axial and radial forces

(Page635)".

3. Align the coupling.

When a motor is used with a ange coupling, the radial deviation must be smaller than

0.03 mm; otherwise, the bearing will be damaged. The required alignment accuracy varies

with the motor speed and the coupling type. Determine the accuracy according to actual

applications.

– Rotate the motor shaft and the machine shaft to align the coupling.

– An

alignment

accur

acy test is preferred. If unachievable, judge the accuracy by observing

whether the coupling can slide smoothly on both shafts.

4. Realign the coupling.

If the coupling gives out abnormal sounds, refer to Step 3 "Align a coupling" to realign the

coupling until the sounds disappear.

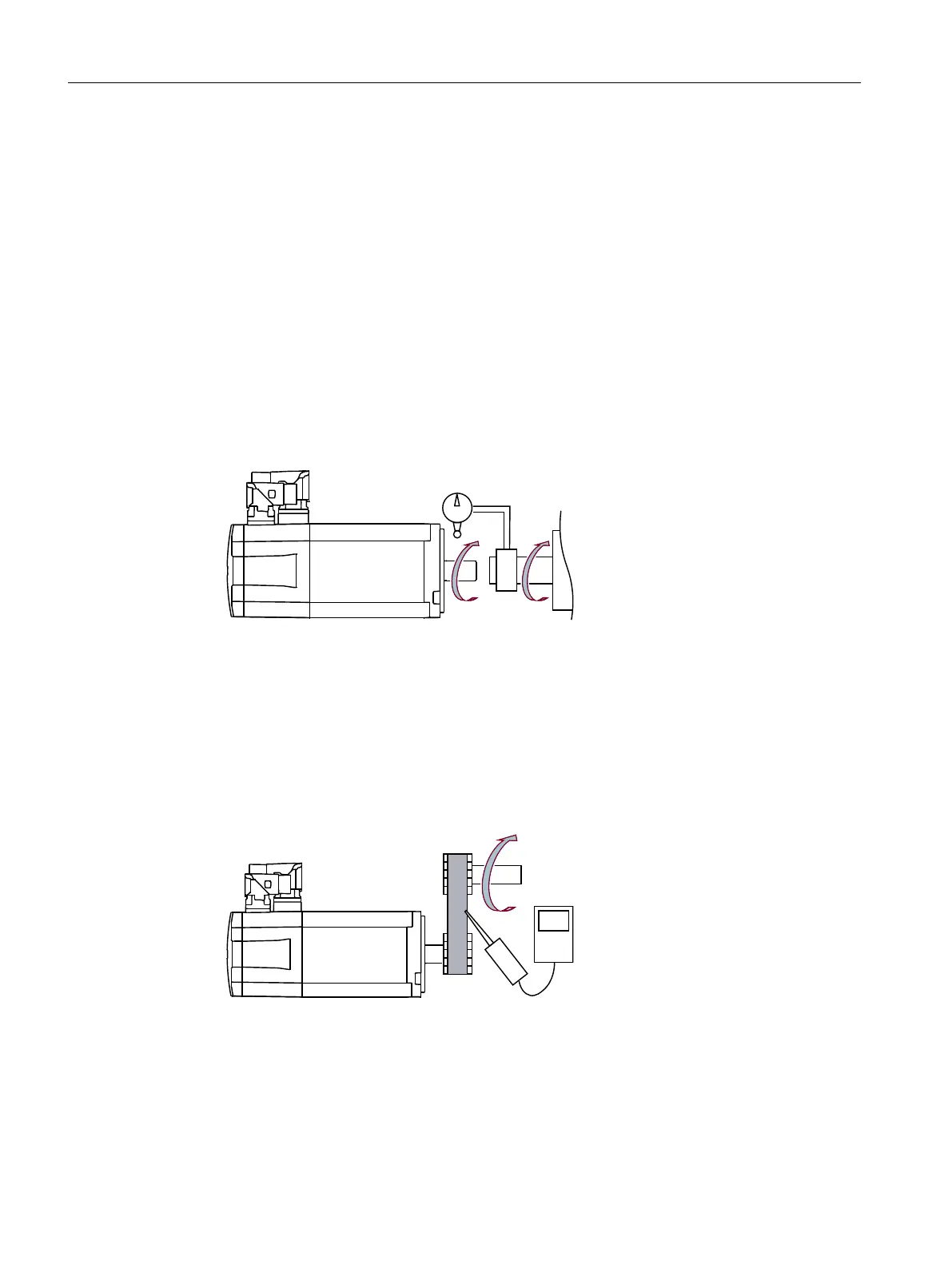

5. Measure tension.

The belt tension must be smaller than the allowable radial forces of the motor.

– Measur

e the belt tension at multiple points using a tension meter while turning the motor

shaf

t b

y 45°.

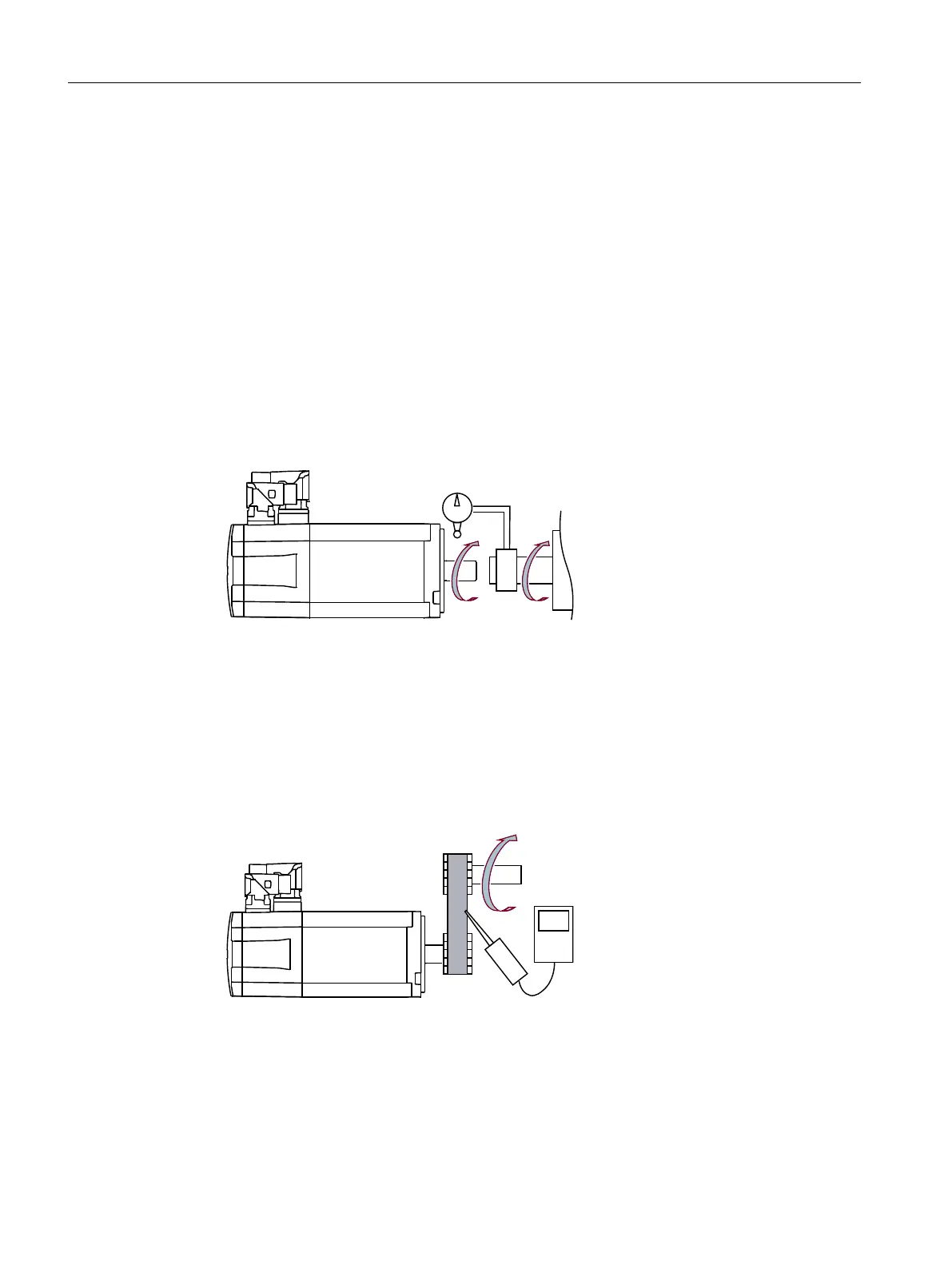

– Reduce the axial misalignment of the belt-pulleys to keep the axial forces to the motor

shaft to a minimum.

Mounting

5.2Motor

SINAMICS S200 PROFINET servo drive system with SIMOTICS S-1FL2

122 Operating Instructions, 11/2023, FW V6.3, A5E51646752B AB

Loading...

Loading...