Section 04 TRANSMISSION

Sub-Section 02 (DRIVE BELT)

04-02-2

DRIVE BELT DEFLECTION

MEASUREMENT 2

NOTE :

The drive belt deflection measure-

ment must be performed each time a new

drive belt is installed.

NOTE :

To obtain an accurate drive belt de-

flection measurement, it is suggested to al-

low a break-in period of 50 km (30 mi).

Before checking the belt deflection, ensure vehi-

cle has the proper belt (Refer to the application

chart).

Adjust pulley distance and alignment. Refer to 04-

05 PULLEY DISTANCE AND ALIGNMENT.

To obtain maximum vehicle performance, the belt

tension must be adjusted according to specifica-

tions shown in the accompanying chart.

†

For reference only

To Check Tensi on

Position a reference rule on drive belt.

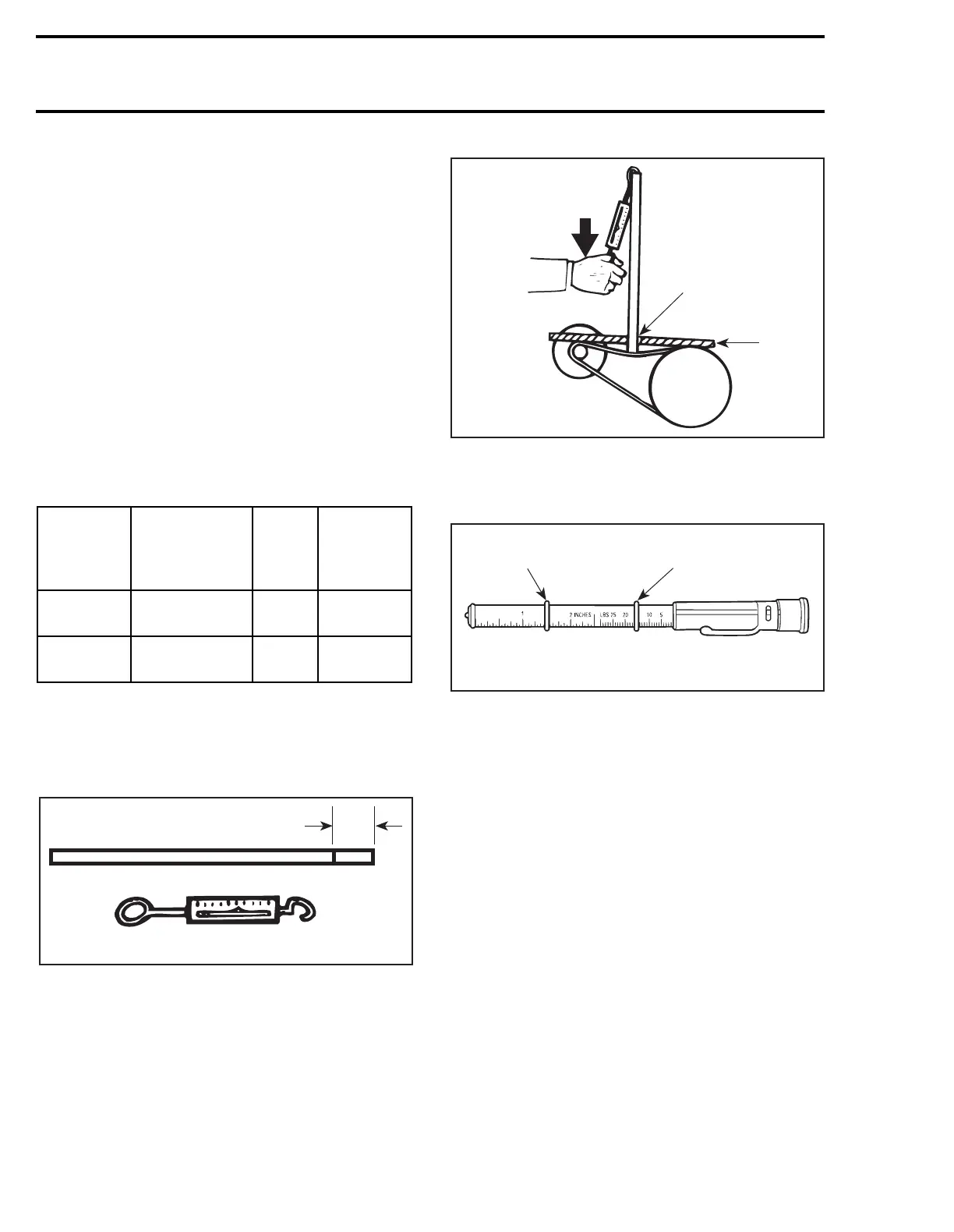

Wooden Stick and Spring Scale Method :

1. Mark specified deflection

Using spring scale and stick, apply specified force

on drive belt halfway between pulleys as shown.

1. Read deflection here

2. Reference rule

3. Force

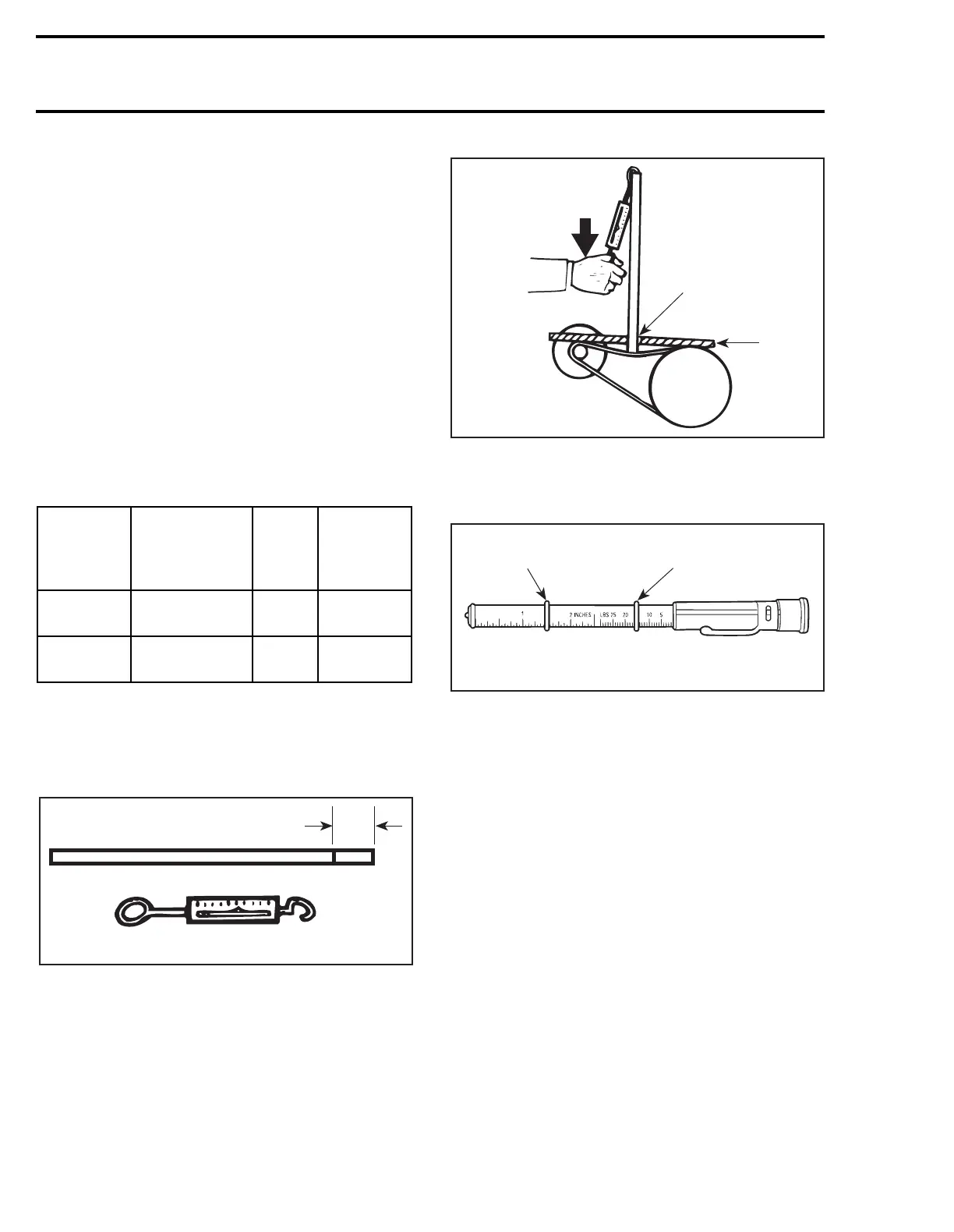

Or use the belt tension tester (P / N 414 3482 00).

1. Lower O-ring

2. Upper O-ring

3. Force (Read Down)

4. Deflection (Read Up)

1. Slide lower O-ring of deflection scale to speci-

fied measure.

2. Slide upper O-ring to zero on the force scale.

3. Apply pressure until lower O-ring is flush with

edge of rule and read force on the upper scale

at top edge of O-ring.

MODEL

DEFLECTION

mm (in)

FORCE

kg (lb)

HEIGHT

†

OVER

DRIVEN

PULLEY

Tundra II LT

32

±

5

(1-1/4

±

13/64)

5(11)

0 - 1.5 mm

(0 - 1/16’’)

S-Series

32

±

5

(1-1/4

±

13/64)

11.3

(25)

0 - 1.5 mm

(0 - 1/16’’)

'

A00D05A

1

A00D06A

1

2

3

12

34

{

{

A00C07B

Loading...

Loading...