Section 04 TRANSMISSION

Sub-Section 06 (BRAKE)

04-06-6

INSPECTION

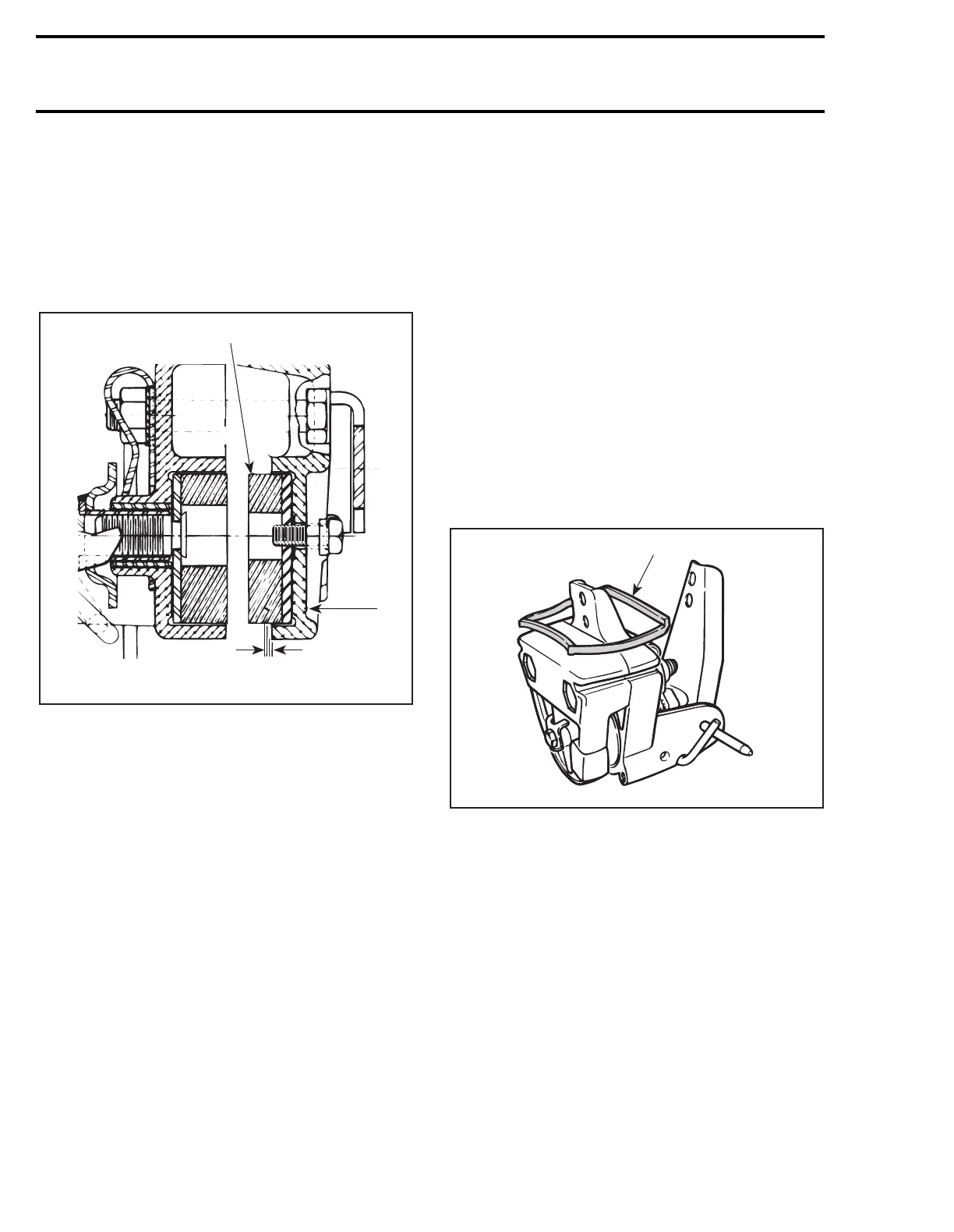

7, Brake Pad Thickness

Brake pads must be replaced when

fixed

pad

projects only 1 mm (1/32 in) from caliper.

CAUTION : Brake pads must always be re-

placed in pairs.

TYPICAL

1. Fixed pad

2. Inner caliper

A. 1 mm (1/32 in) minimum

Brake Disc

Check for scoring, cracking or heat discoloration,

replace as required. Refer to DRIVEN PULLEY 04-

04 for replacement procedures on Tundra II LT.

CAUTION : Brake disc should never be

machined.

ASSEMBLY

14, Ratchet Wheel

Apply low temperature grease (P / N 413 7061 00)

on threads and spring seat prior to installing. Fully

tighten then back off one turn.

16, Pin

Install so that it can only be removed upward.

Lock it in the caliper casting notch.

7, Fixed Brake Pad

Tundra II LT

Torque screw

no. 3

to 4 N•m (35 lbf•

in

). Bend

locking tab

no. 4

over a flat of screw head.

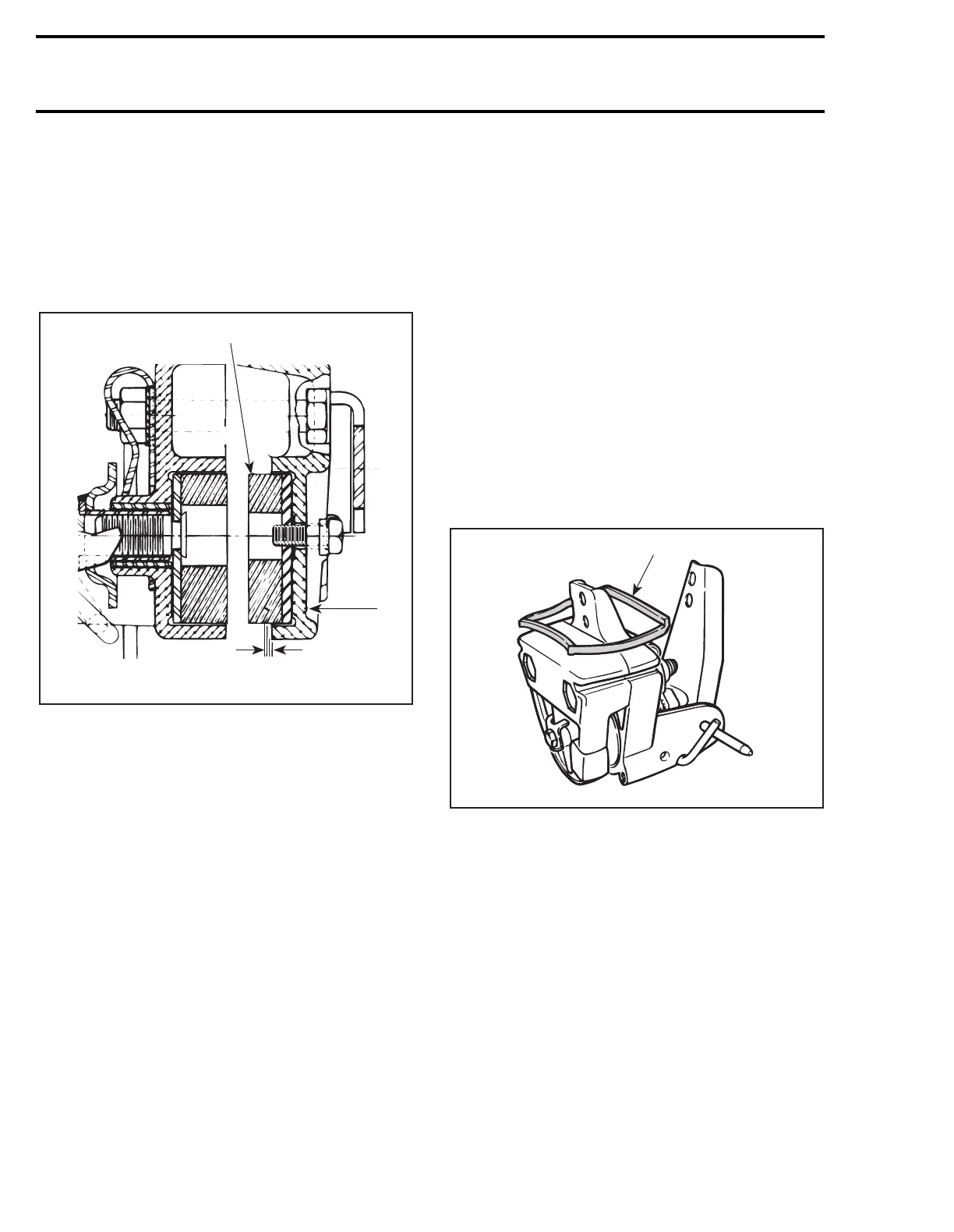

1,6,11,12, Locking Tab, Inner, Outer

Caliper and Nut

Tundra II LT

Assemble both caliper halves. Insert bolts

no. 9

,

locking tab

no. 20

, then nuts. Torque nuts to 24

N•m (18 lbf•ft). Caliper half side slots must align

to allow proper sliding in brake support. Bend

locking tab over a flat of each nut.

Install rubber slider

no. 12

lubricated with short-

ening (cooking fat) into side slots of caliper. It

must be installed so that the raised edge is up-

ward and on the same side of nuts as shown.

1. Raised edge upward and same side of nuts

CAUTION : Positioning of rubber slider is

important to avoid the possibility of dam-

age against locking tab edges.

INSTALLATION

To install brake, reverse removal procedure paying

attention to the following.

WARNING : Avoid getting oil on brake

pads. Do not lubricate or apply antirust or

antifreeze solution in brake cable.

17, Brake Disc

S-Series

The brake disc must be floating on countershaft

for efficient operation of brake.

A15D03A

A

2

1

A20D04A

1

;

Loading...

Loading...