Section 03 ENGINE

Sub-Section 02 (277 ENGINE TYPE)

03-02-4

TROUBLESHOOTING

Before completely disassemble engine, check air-

tightness. Refer to LEAK TEST AND ENGINE DI-

MENSION MEASUREMENT 03-04.

NOTE :

The following procedures can be

done without removing the engine from

chassis.

TOP END REMOVAL (without

removing engine from chassis)

Remove the following then lift cylinder head

no. 3

and cylinder

no. 4

:

– belt guard

– carburetor

– exhaust system

– spark plug

– oil injection inlet

– fan cowl and hood cable

– cylinder head nuts

no. 1

and washers

no. 2

CLEANING

Discard all gaskets.

Clean all metal components in a non-ferrous met-

al cleaner.

Scrape off carbon formation from cylinder ex-

haust port, cylinder head and piston dome using a

wooden spatula.

NOTE :

The letters “AUS” (over an arrow on

the piston dome) must be visible after clean-

ing.

Clean the piston ring grooves with a groove clean-

er tool, or with a piece of broken ring.

DISASSEMBLY

5, Piston

On this engine, piston pin needle bearing

no. 6

is

mounted without a cage.

Use piston pin puller (P / N 529 0210 00) along

with expansion sleeve and locating sleeve.

Place a clean cloth or rubber pad (P / N 529 0234

00) over crankcase to prevent circlips

no. 8

from

falling into crankcase. Then with a pointed tool in-

serted in piston notch, remove circlips from pis-

ton

no. 5

.

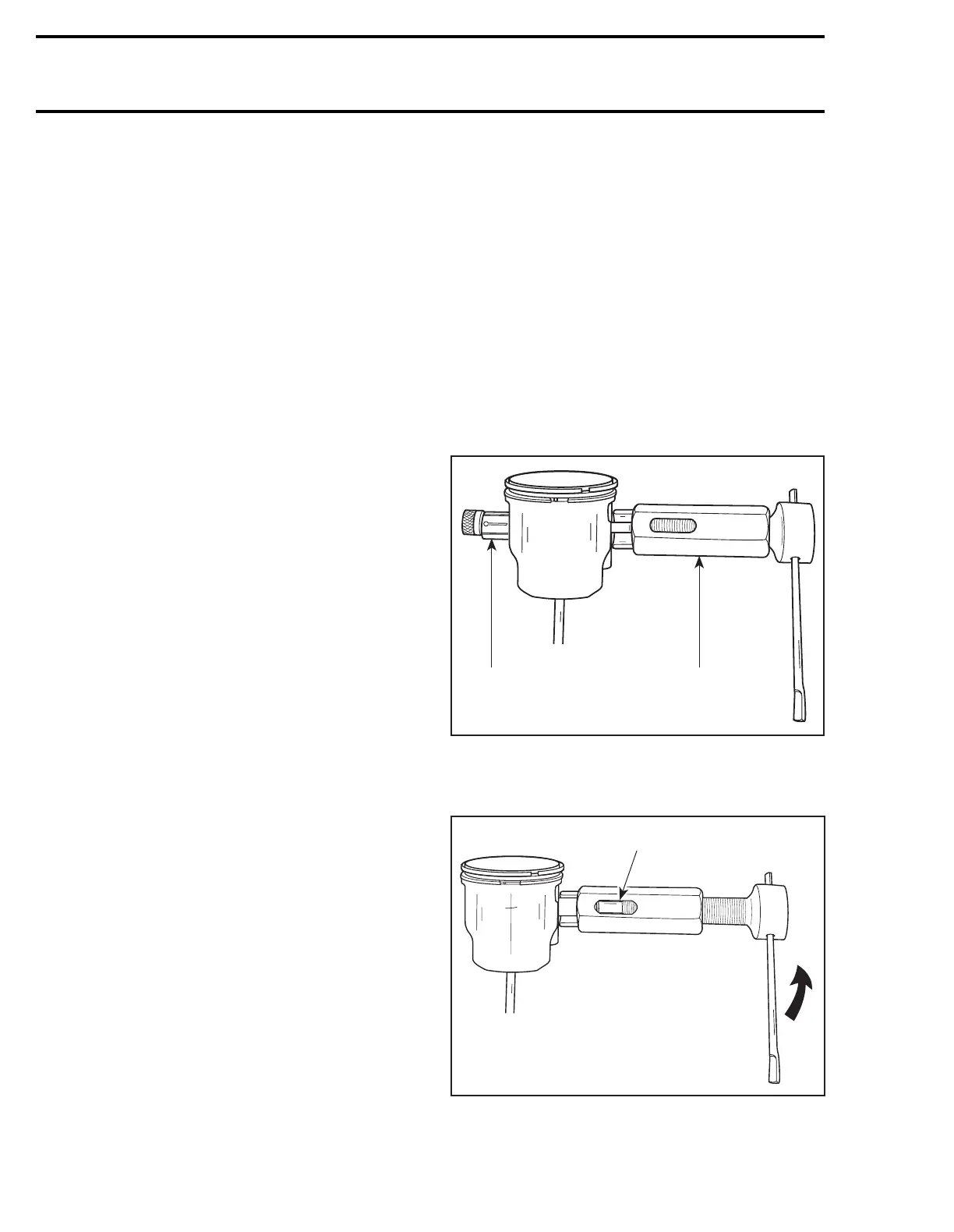

Insert piston pin puller (P / N 529 0210 00) then

install expansion sleeve over puller rod.

1. Expansion sleeve

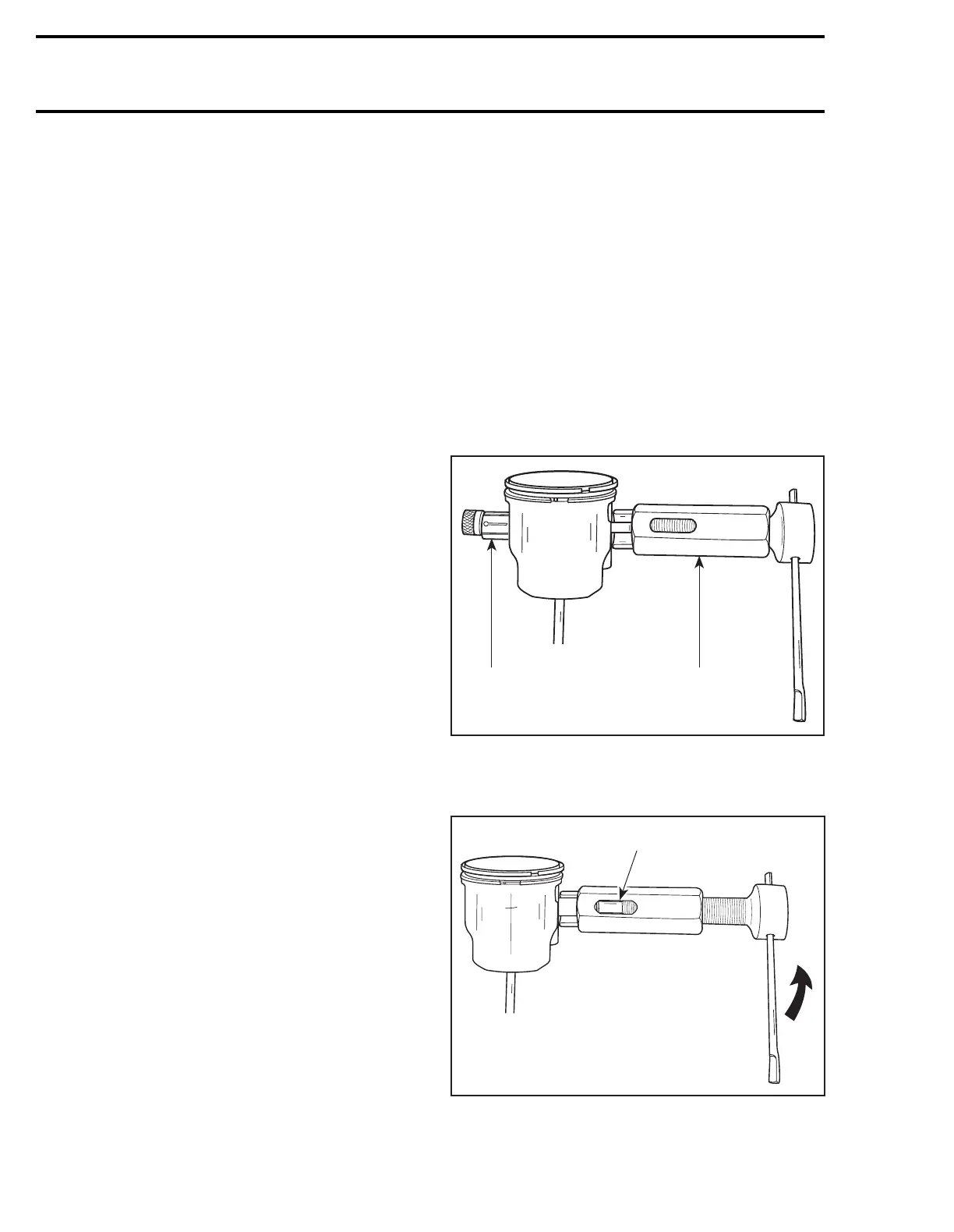

Pull out piston pin

no. 7

by unscrewing puller until

first thread of puller rod aligns with 277 mark.

1. 277 mark on puller

Screw in puller in order to remove it from piston.

'

A21C06A

1

529 0210 00

A21C05A

1

Loading...

Loading...