Section 03 ENGINE

Sub-Section 05 (CDI SYSTEM)

03-05-6

NOTE :

The following procedures can be

done without removing the engine from

chassis.

CLEANING

Clean all metal components in a non-ferrous met-

al cleaner.

CAUTION : Clean armature and magneto

using only a clean cloth.

DISASSEMBLY

To gain access to magneto assembly, remove the

following parts as needed on different engines :

– tuned pipe and muffler

– oil injection pump mounting plate from rewind

starter

– rewind starter

– starting and V-belt pulleys

NOTE :

Before disassembling armature

plate, indexing marks should be scribed to

facilitate reassembly.

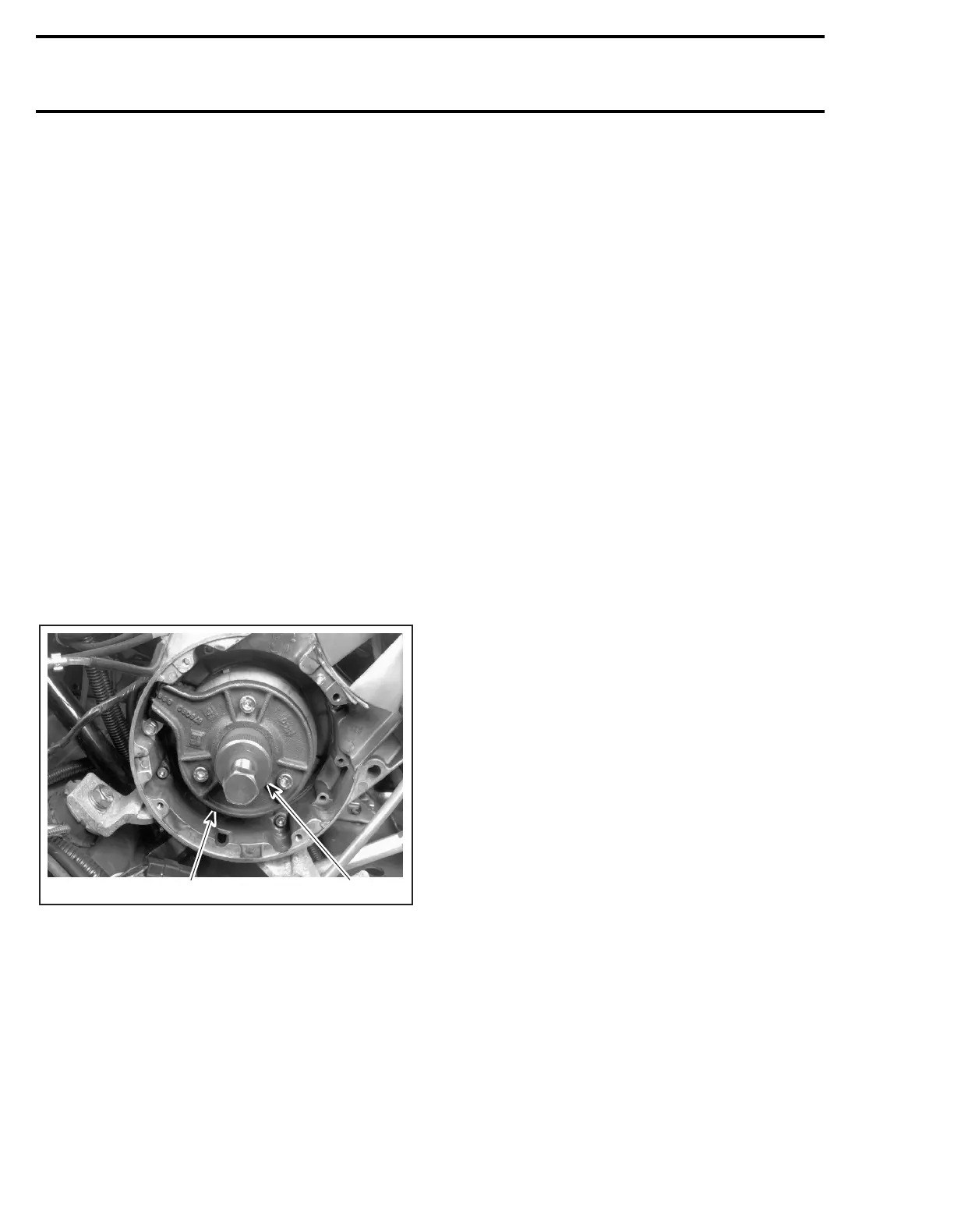

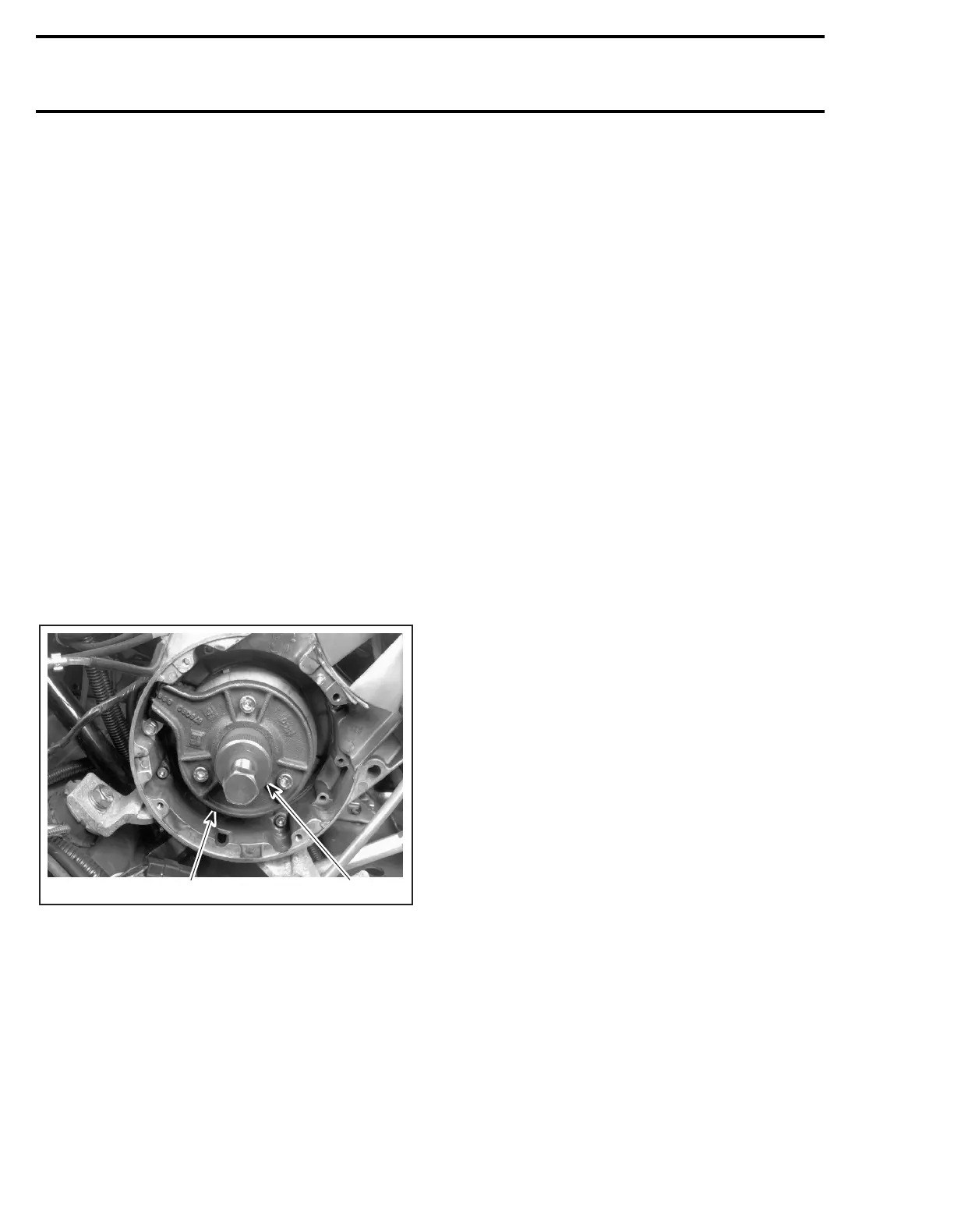

To remove magneto flywheel retaining nut

no. 3

,

install puller ring (P/N 420 8760 80) and M8 x 20

screws.

– Remove magneto flywheel nut, using a 30 mm

socket machined to 40 mm (1.580 in) outside

diameter by 16 mm (5/8 in) long.

NOTE :

To correctly remove a threadlocked

fastener it is first necessary to tap on the fas-

tener to break threadlocker bond. This will elimi-

nate the possibility of thread breakage.

To remove magneto flywheel

no. 2

, install the

magneto puller (P/N 529 0225 00).

– Tighten puller bolt and at the same time, tap on

bolt head using a hammer to release magneto

flywheel from its taper.

REPAIR

To replace generator coil

no. 1

:

– Heat the armature plate to 93°C (200°F) around

the screw holes to break the threadlocker

bond.

To replace trigger coil

no. 4

:

– Disconnect trigger coil wire (RED).

– Remove grommet from crankcase where trig-

ger coil wire exits magneto housing.

– Remove retaining screws

no. 9

.

– Remove trigger coil and carefully pull wire.

– Install new trigger coil and other parts re-

moved.

Adjustment

Whenever the trigger coil or the magneto fly-

wheel is removed or replaced, the air-gap be-

tween the trigger coil and the flywheel protrusion

must be checked and adjusted. The purpose of

this adjustment is to obtain the minimum clear-

ance between these parts – without touching at

any RPM – so that the trigger coil produces its

proper electrical output. Ignition timing must also

be checked.

Proceed as follows :

1. Rotate flywheel so that one protrusion aligns

with trigger coil.

2. Using a feeler gauge of 0.45 mm (.018 in) to

0.55 mm (.022 in) thick, check air-gap between

center pole of trigger coil and flywheel protru-

sion.

3. If necessary, adjust by slackening retaining

screws and moving trigger coil toward or away

of protrusion.

4. Retighten screws and recheck air-gap.

A03C07A

529 0225 00420 8760 80

Loading...

Loading...