Section 04 TRANSMISSION

Sub-Section 03 (DRIVE PULLEY)

04-03-7

Reclean mounting surfaces with paper towel and

cleaning solvent (P / N 413 7082 00).

Wipe off the mounting surfaces with a clean, dry

paper towel.

CAUTION : Mounting surfaces must be

free of any oil, cleaner or towel residue.

7,20, Bushing

Only use petrol base cleaner when cleaning bush-

ings.

CAUTION : Do not use acetone to clean

bushing.

INSPECTION

Drive pulley should be inspected annually.

16,17, Thrust Washer and Roller

Check roller for roundness of external diameter.

Check thrust washer for thickness wear. Replace

as required.

CAUTION : Ensure rollers are in good

condition. Replace as required.

9,12, Fitting Bolt Ass’y and Flanged

Bushing

Check for wear, replace as required. When install-

ing old style flanged bushing (made of black plas-

tic), use a size “O” (letter) drill bit to ream inside

diameter.

24,25, O-ring and Slider Shoe

Check if O-rings are cracked, cut or crushed. Re-

place as required.

Check slider shoes for wear. Replace if groove is

not apparent on top.

5,29, Fixed Half and Governor Cup

Inspect splines and free play between both parts.

Maximum free-play is 0.5 mm (.020 in) measured

at calibration screw radius. Replace if required.

7,20, Sliding Half and Spring Cover

Kahrlon Bushing

Visually inspect kahrlon coating. Replace if worn.

Sliding Half Bushing Replacement

Use a suitable pusher to remove the old bushing.

Clean sliding half with ethyl alcohol.

CAUTION : Bushing must be bonded with

retaining compound (P / N 413 7031 00)

then flared to prevent displacement in sliding

half.

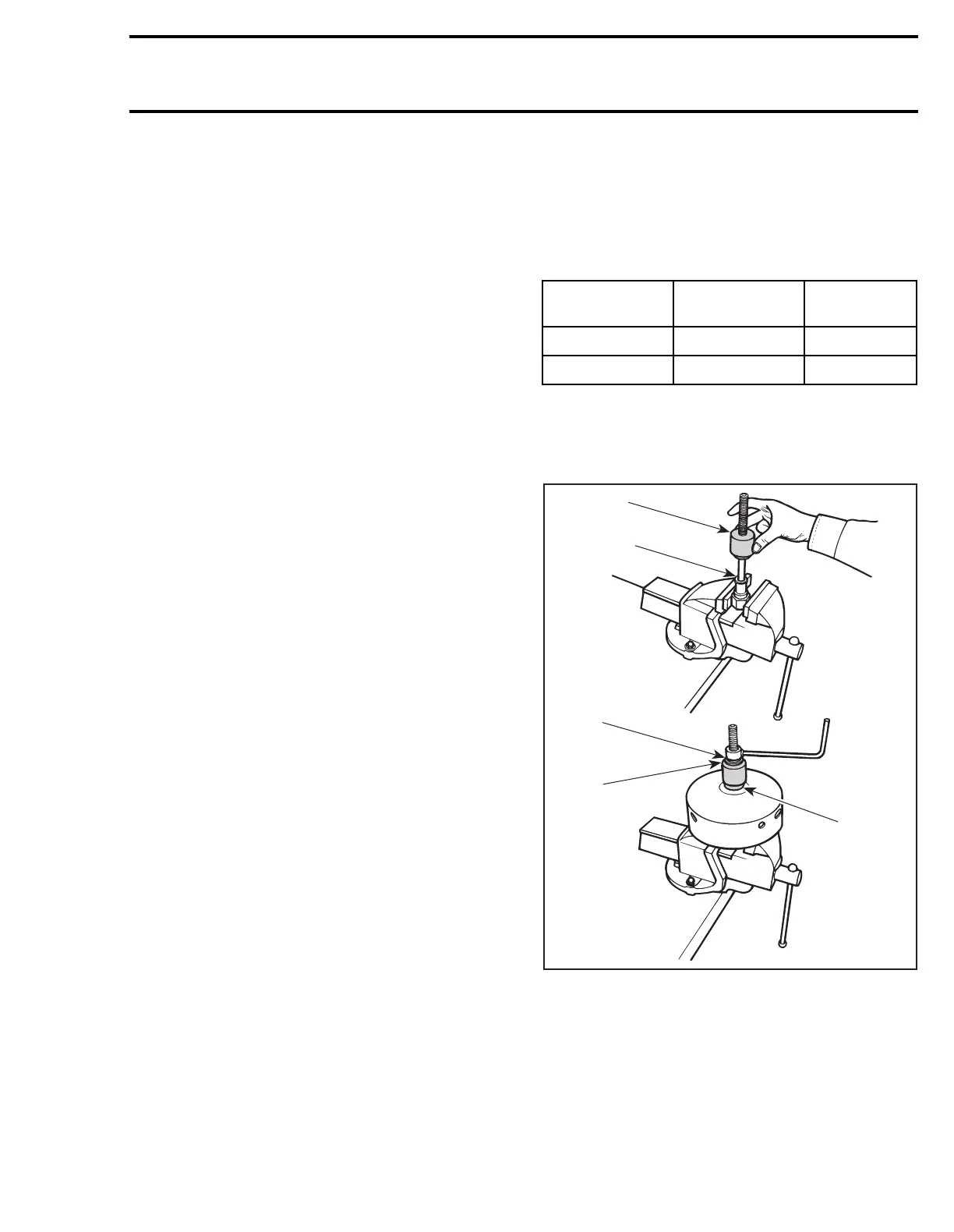

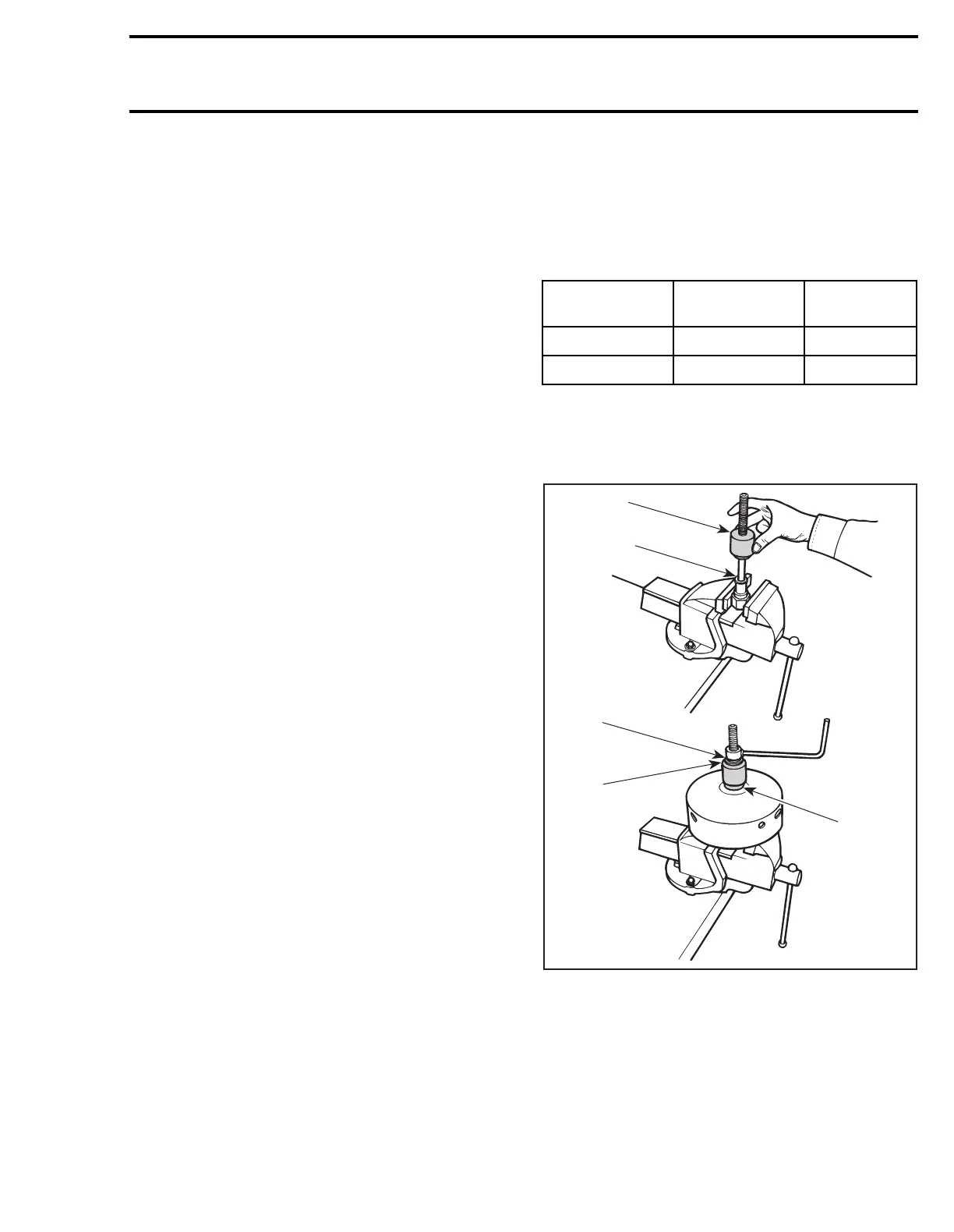

To flare bushing, use spring compressor (P / N

529 0151 00) and appropriate flare tools.

Apply retaining compound (P / N 413 7031 00)

outside of bushing then insert into its housing

making sure there is the same distance both

sides.

1. Washer

2. Flat surface

3. Flaring side

4. Bushing

Then flare bushing.

FLARE

TOOL

STAMPED

LETTER

P / N

INTERIOR C 529 0184 00

EXTERIOR C 529 0185 00

A01B4WA

1

2

3

4

1

Loading...

Loading...