Section 03 ENGINE

Sub-Section 02 (277 ENGINE TYPE)

03-02-5

Remove piston from connecting rod.

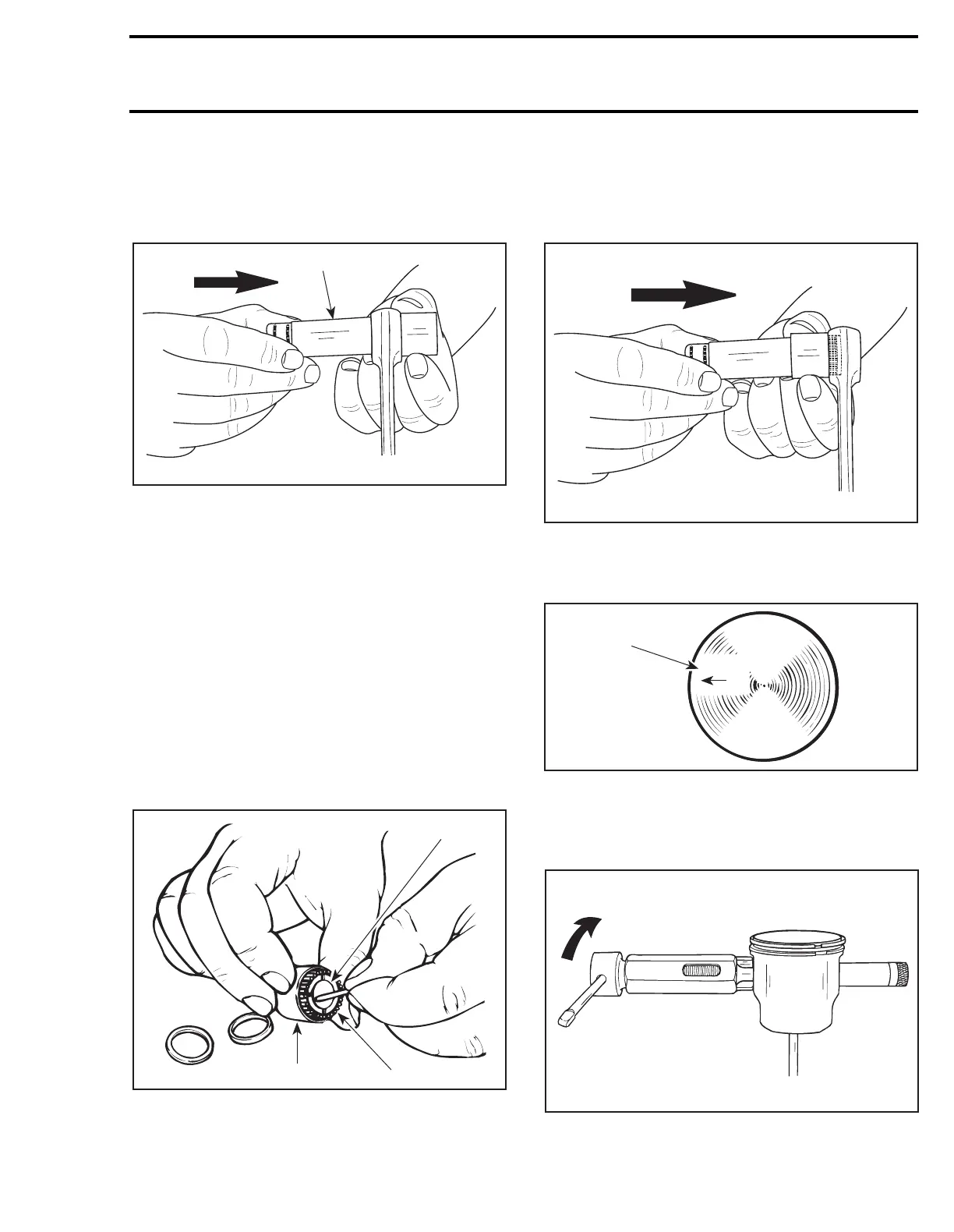

Install locating sleeve. Then push needle bearings

along with thrust washers using a 21 mm (.826 in)

diameter pusher.

1. Pusher 21mm (.826 in)

NOTE :

0.25 and 0.5 mm oversize pistons

and rings are available if necessary.

Use a locking tie to fasten all needles and thrust

washers along with sleeves.

INSPECTION

Refer to LEAK TEST AND ENGINE DIMENSIONS

MEASUREMENT 03-04.

ASSEMBLY

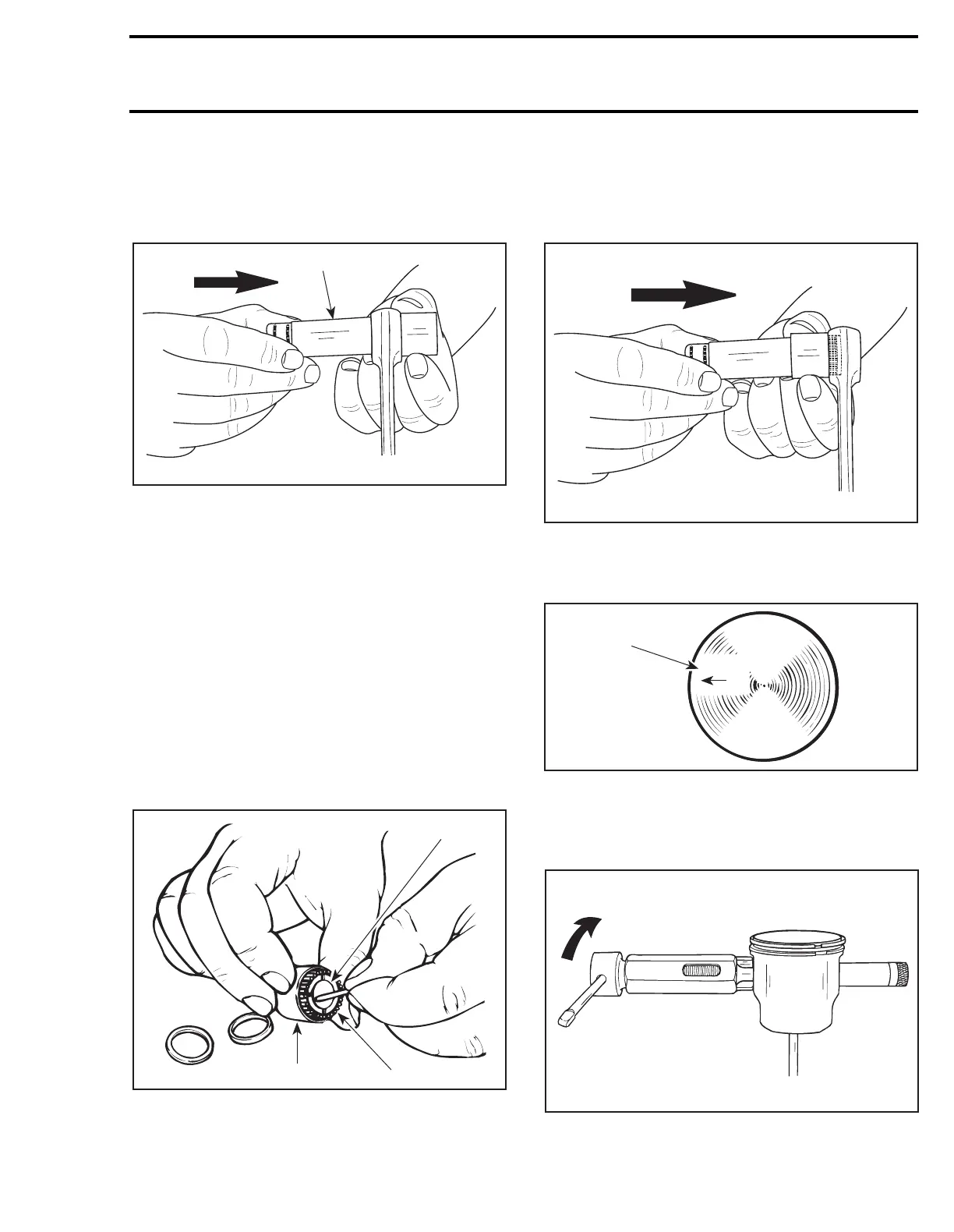

When reinstalling original needle bearings, make

sure that 31 needles are inserted between expan-

sion sleeve and locating sleeve.

1. Expansion sleeve

2. 31 needles

3. Locating sleeves

– Grease thrust washers and install them on each

end of needles.

– Using a 21 mm (.826 in) diameter pusher, insert

needles into connecting rod.

Mount piston over connecting rod with the letters

“AUS” (over an arrow on the piston dome) facing

in the direction of exhaust port.

1. Exhaust

Install piston pin puller (P / N 529 0210 00) and

turn handle until piston pin is correctly positioned

in piston.

Remove piston pin puller and expansion sleeve.

A21C04A

1

'

A21C03A

1

23

A21C02A

A01C01A

AUS

1

A21C01A

Loading...

Loading...