Section 03 ENGINE

Sub-Section 04 (LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

03-04-8

CONNECTING ROD / CRANKPIN

CLEARANCE

CRANKSHAFT END-PLAY

277 Engine Type

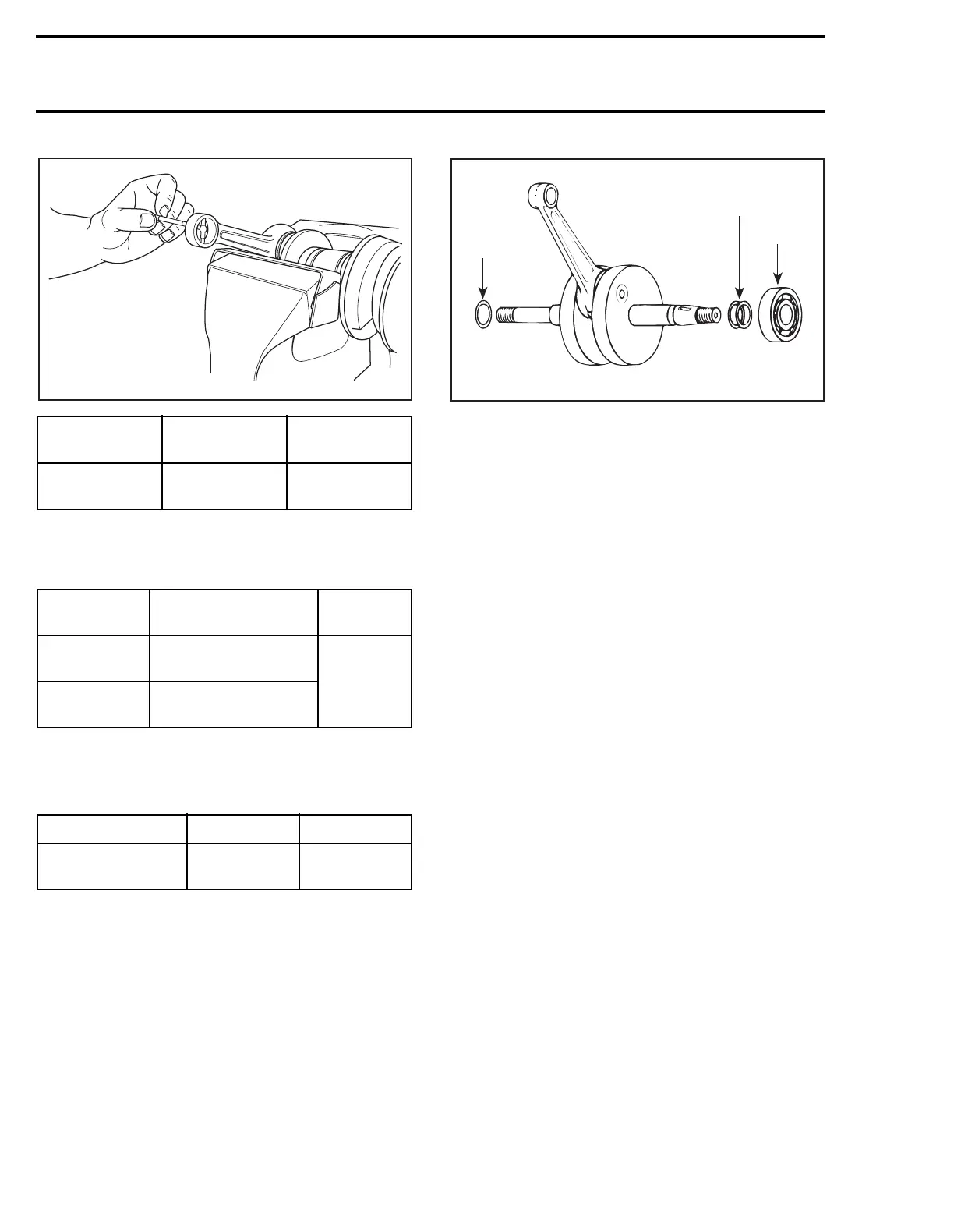

Adjustment

Crankshaft end-play is adjusted with shims locat-

ed between crankshaft and magneto side bear-

ing.

1. Distance ring

2. Shim location

3. Bearing

4. PTO

5. MAG

CAUTION : Always install end-play ad-

justment shims on the magneto side be-

tween bearing and crankshaft counterweight.

The following is required for the adjustment

procedure :

– adjustment shims (refer to parts catalog)

thicknesses available : 0.10 mm (.004 in)

0.20 mm (.008 in)

0.30 mm (.012 in)

0.50 mm (.020 in)

1.00 mm (.040 in)

– micrometer

– caliper

Total shim thickness needed for the end-play ad-

justment is determined with the following

procedure :

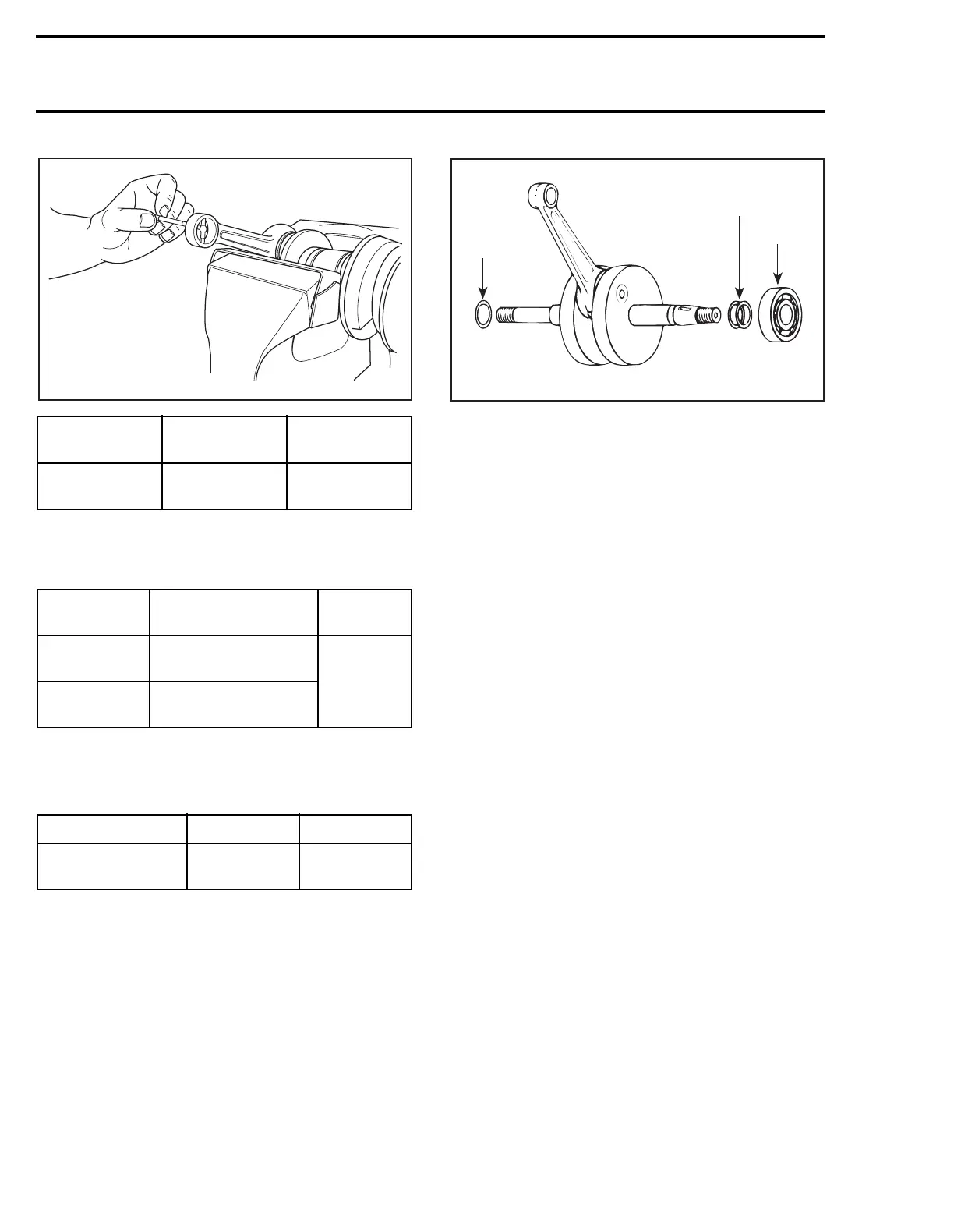

a. Measure crankcase halves as illustrated (M

1

and M

2

).

A standard compressed crankcase gasket will

have a 0.30 mm (.012 in) thickness (M

3

).

Add

these measurements to obtain dimension A.

ENGINE

TYPE

NEW PARTS

MIN. - MAX.

WEAR

LIMIT

All

0.03-0.012 mm

(.0001-.0005 in)

0.015 mm

(.0006 in)

ENGINE

TYPE

NEW PARTS

MIN. – MAX.

WEAR

LIMIT

277

0.020 – 0.030 mm

(.0008 – .0012 in)

0.05 mm

(.0020 in)

377, 443 and

503

0.020 – 0.033 mm

(.0008 – .0013 in)

ENGINE TYPE MINIMUM MAXIMUM

277

0.10 mm

(.004 in)

.030 mm

(.012 in)

A01C3HA

A01C1NA

3

1

5

4

2

Loading...

Loading...