Section 04 TRANSMISSION

Sub-Section 06 (BRAKE)

04-06-5

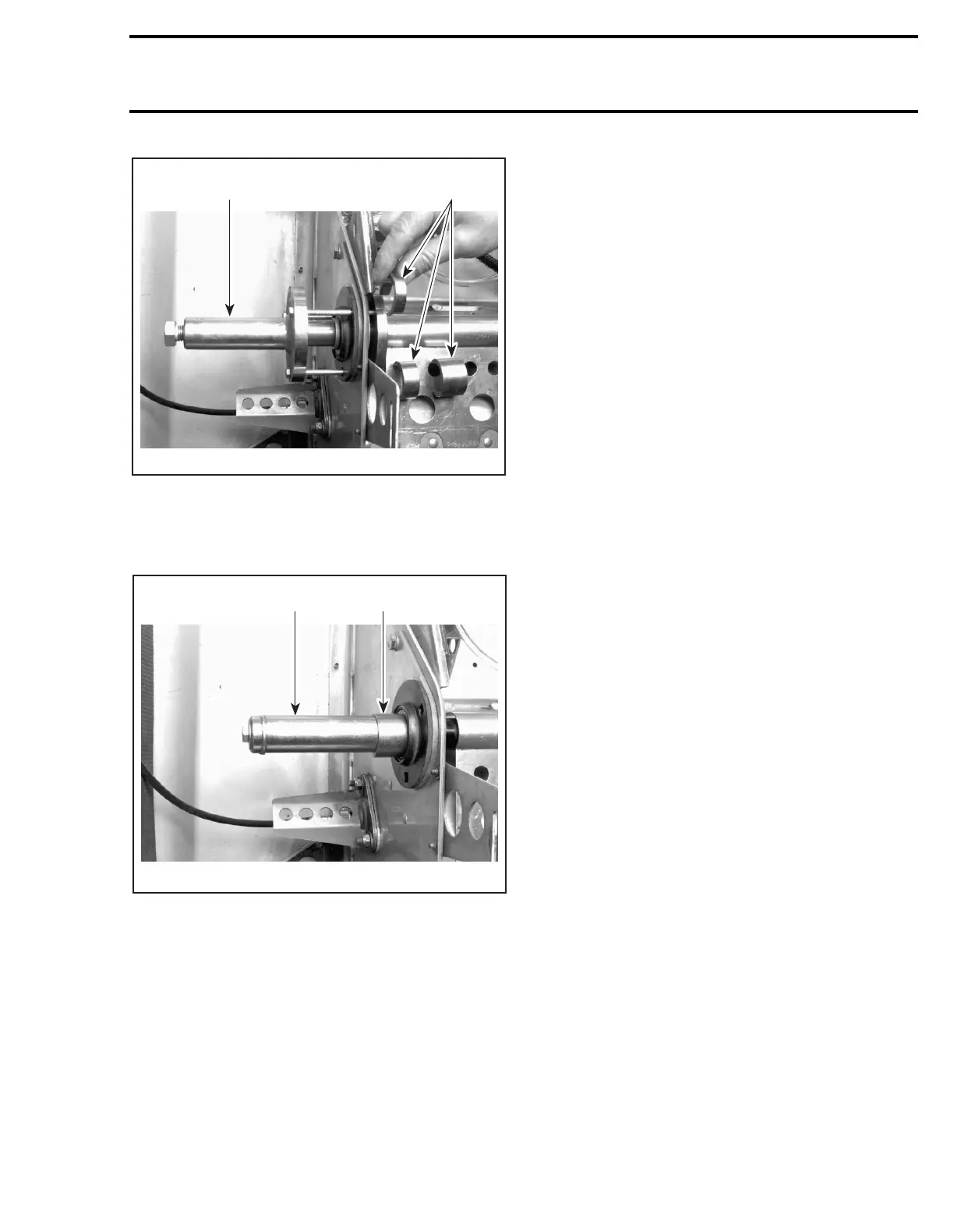

1. Spacers

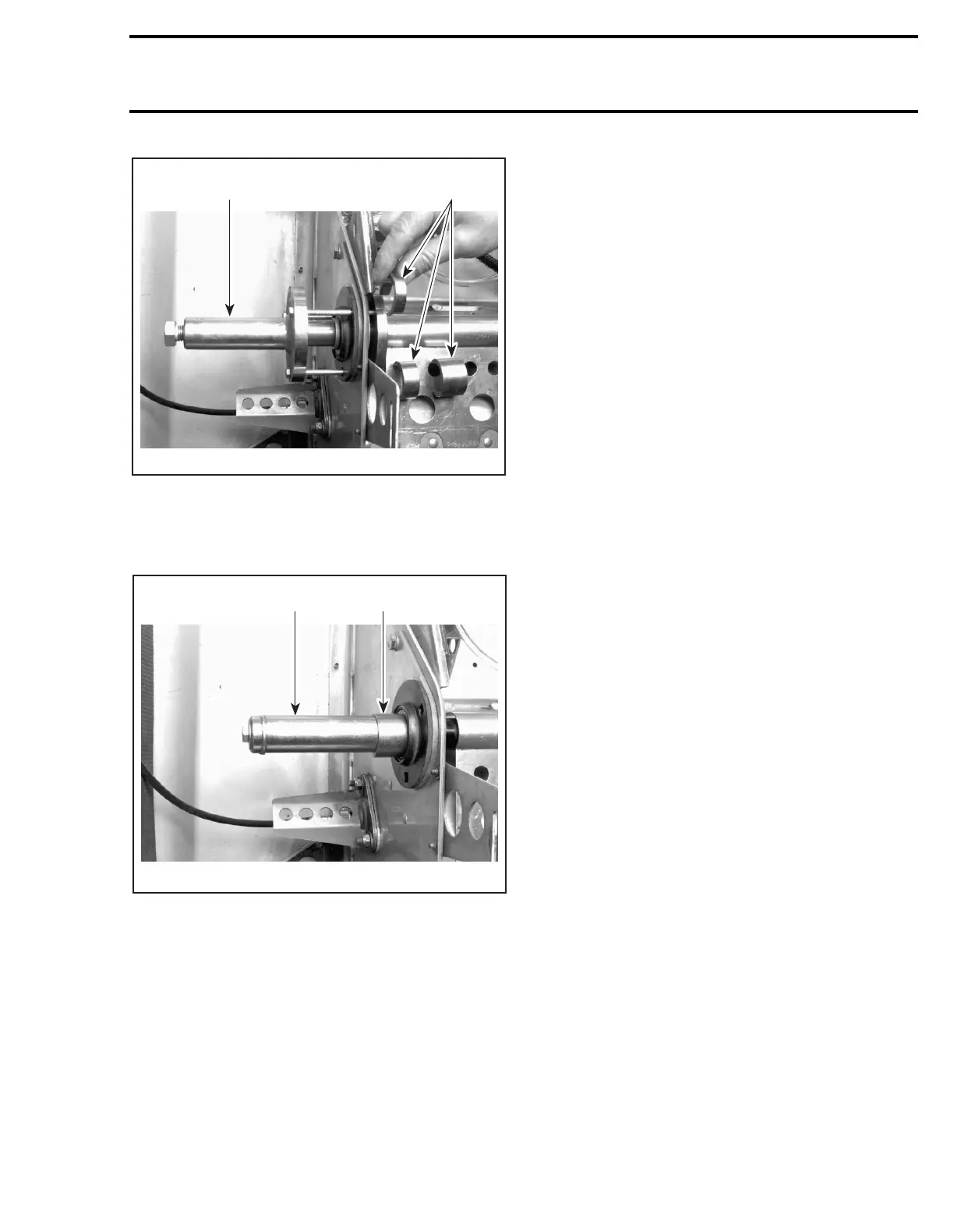

To install bearing on countershaft, use installer (P / N

529 0302 00) and spacer(s) from remover as re-

quired.

1. Spacer

COUNTERSHAFT AND BRAKE DISC REMOVAL

S-Series with Hydraulic Brake

– Remove muffler.

– Refer to CHAINCASE 04-07 in order to remove

chaincase cover.

– Remove upper sprocket castellated nut.

– Remove belt guard, drive belt and driven pulley

referring to DRIVEN PULLEY 04-04.

– Slacken set screw and unlock collar

no. 18

if

bearing is needed to be disassembled. See

above S-Series illustration and procedure.

– Remove 3 retaining screws

no. 20

from coun-

tershaft bearing housing.

– Unbolt oil reservoir support to make room for

countershaft or brake disc removal.

– Pull countershaft toward driven pulley side to

gain access to clip

no. 25

.

– Remove clip

no. 25

on countershaft.

– Pull countershaft toward driven pulley side to

free from chaincase. Withdraw countershaft to-

ward chaincase.

– Remove connecting pipe between tuned pipe

and after muffler.

– Disconnect brake line from caliper and plug it.

– Unbolt caliper from chaincase.

– Remove brake disc from countershaft.

DISASSEMBLY

7,15,16,23, Brake Pad, Brake Lever, Pin

and Screw

All Models with Mechanical Brake

Pull pin out off caliper and remove lever.

On Tundra II LT, remove self-tapping screw. Un-

screw ratchet wheel in order to remove moving

pad.

Remove fixed pad.

S-Series with Mechanical Brake

Fixed pad is riveted to chaincase on these mod-

els. Caliper must be split to remove moving pad.

To removed fixed pad, drill out its rivet then pry

disc in order to free fixed pad.

All Models with Hydraulic Brake

Only brake pads are available as spare parts. If cal-

iper or master cylinder are damaged, replace each

of them as an assembly.

CLEANING

Clean all metal components in a general purpose

solvent. Thoroughly dry all components before as-

sembling.

CAUTION : Do not clean brake pads in sol-

vent. Soiled brake pads must be replaced

by new ones.

A03D1JA

529 0301 00 1

A03D1KA

529 0302 00 1

Loading...

Loading...