Section 03 ENGINE

Sub-Section 06 (OIL INJECTION SYSTEM)

03-06-3

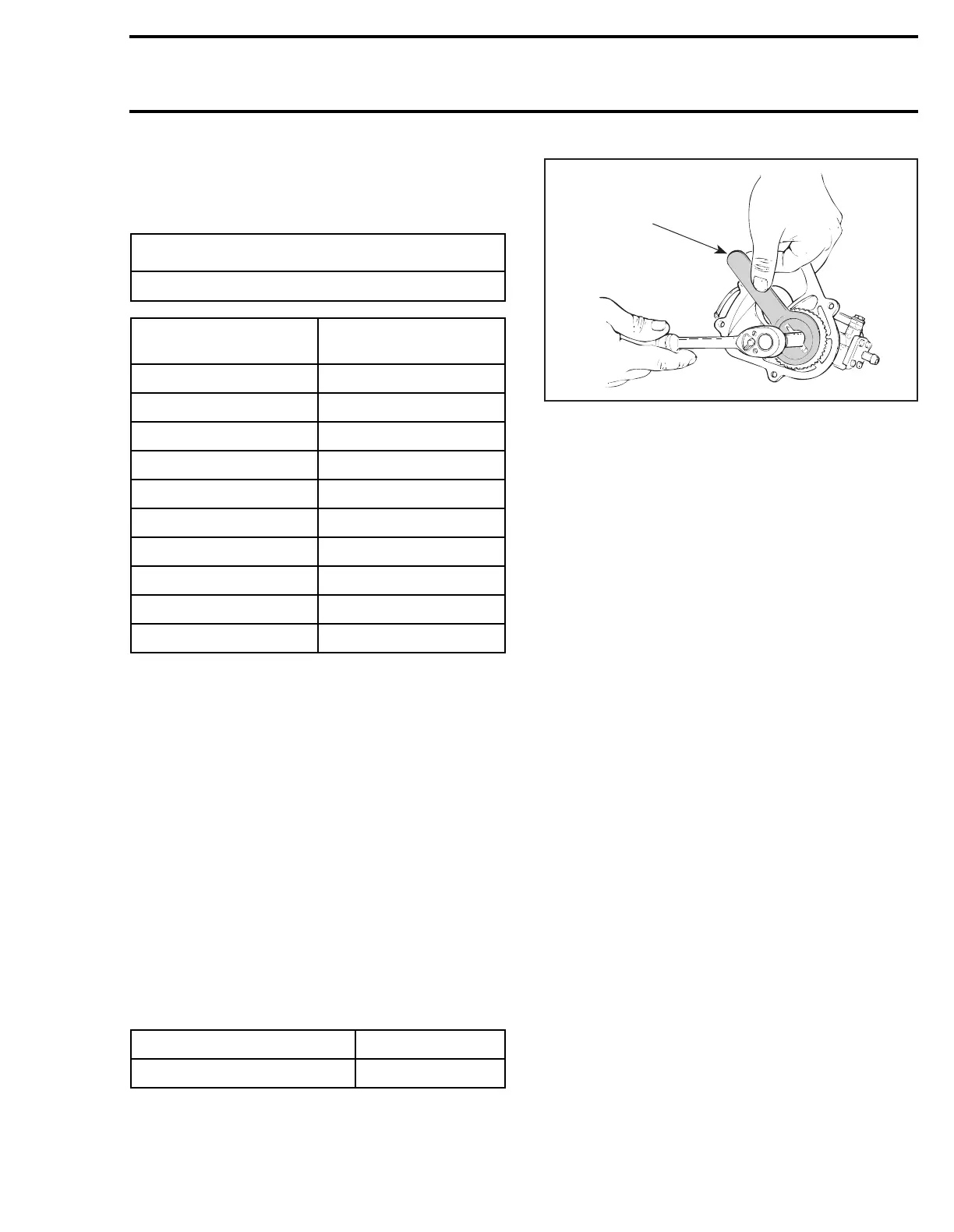

OIL PUMP IDENTIFICATION

Different engines use different pumps. See iden-

tification on lever

no. 7

.

NOTE:

The following procedures can be

done without removing the engine from

chassis.

CLEANING

Clean all metal components in a non-ferrous met-

al cleaner.

DISASSEMBLY

NOTE:

Some oil pump components are not

available as single parts.

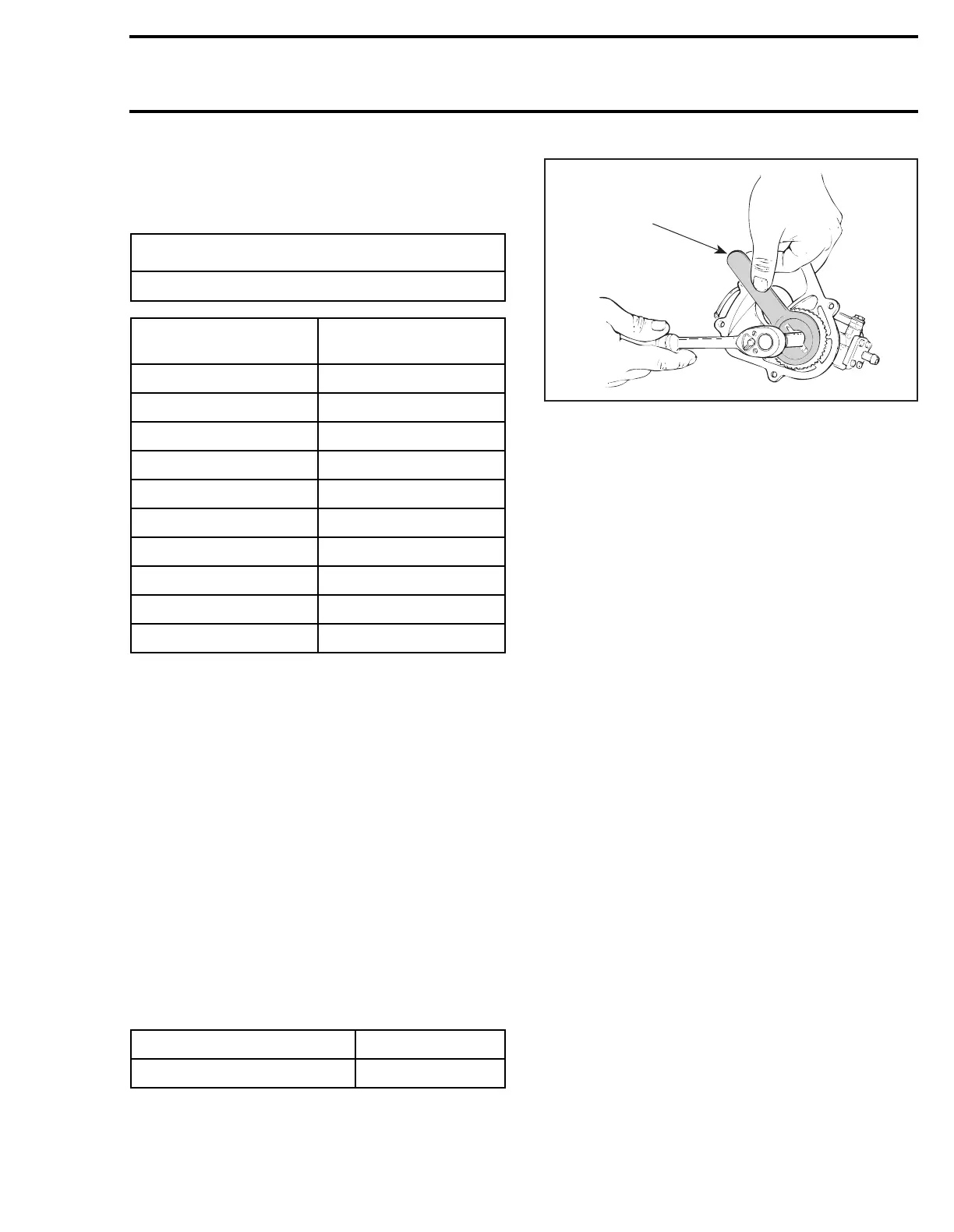

1,2, Gear Retaining Nut and Oil Pump

Gear

To remove gear retaining nut, first extract the nee-

dle roller with pliers then lock gear in place using

one of the following gear holde:

TYPICAL

ASSEMBLY

2, Oil Pump Gear

At gear assembly, apply a light coat of Molykote

111 (P/N 413 7070 00) on gear teeth.

4, Needle Roller

(fan cooled engine only)

The needle roller must be engaged as deep as

possible in the pump mounting flange.

5,6, Spring Clip and Clamp

Always check for spring clips and clamps tight-

ness.

3, Screw

Torque to 9 N•m (80 lbf•

in

).

Make sure cable barrel is well seated in oil pump

lever.

Secure barrel with plastic washer and circlip.

Verify cable and oil pump lever operation.

ADJUSTMENT

Prior to adjusting the pump, make sure all carbu-

retor adjustments are completed.

Synchronizing Pump with Carburetor:

Eliminate the throttle cable free-play by pressing

the throttle lever until a light resistance is felt,

then hold in place. The aligning marks on the

pump casting and on the lever must align. If not,

loosen the adjuster nut and adjust accordingly.

Retighten the adjuster nut.

-

CAUTION

Always mount proper pump on engine.

ENGINE TYPE

OIL PUMP

IDENTIFICATION

443 MX Z

E4

454 N4

494 Skandic WT LC N4

494 Formula N4

503 Skandic WT/SWT E4

583 GT N6

583 MX Z N6

583 Summit N2

670 MX Z N6

670 Summit N6

ENGINE TYPE TOOL P/N

443/454/494/503/583/670 420 2779 05

A00C17A

420 2779 05

Loading...

Loading...