Section 04 TRANSMISSION

Sub-Section 03 (DRIVE PULLEY)

04-03-5

GENERAL

Some drive pulley components (return spring,

ramp) can be changed to improve vehicle perfor-

mance in high altitude regions. The High Altitude

Technical Data booklet (P / N 484 0624 00 and 484

0545 00 for binder) gives information about cali-

bration according to altitude.

CAUTION : Such modifications should

only be performed by experienced me-

chanics since they can greatly affect vehicle

performance. Verify spring specifications be-

fore installation. Do not only refer to the spring

color code.

NOTE :

TRA clutch stands for Total Range

Adjustable clutch.

WARNING : Any drive pulley repairs must

be performed by an authorized Bombar-

dier snowmobile dealer, or other such quali-

fied person. Sub-component installation and

assembly tolerances require strict adherence

to procedures detailed.

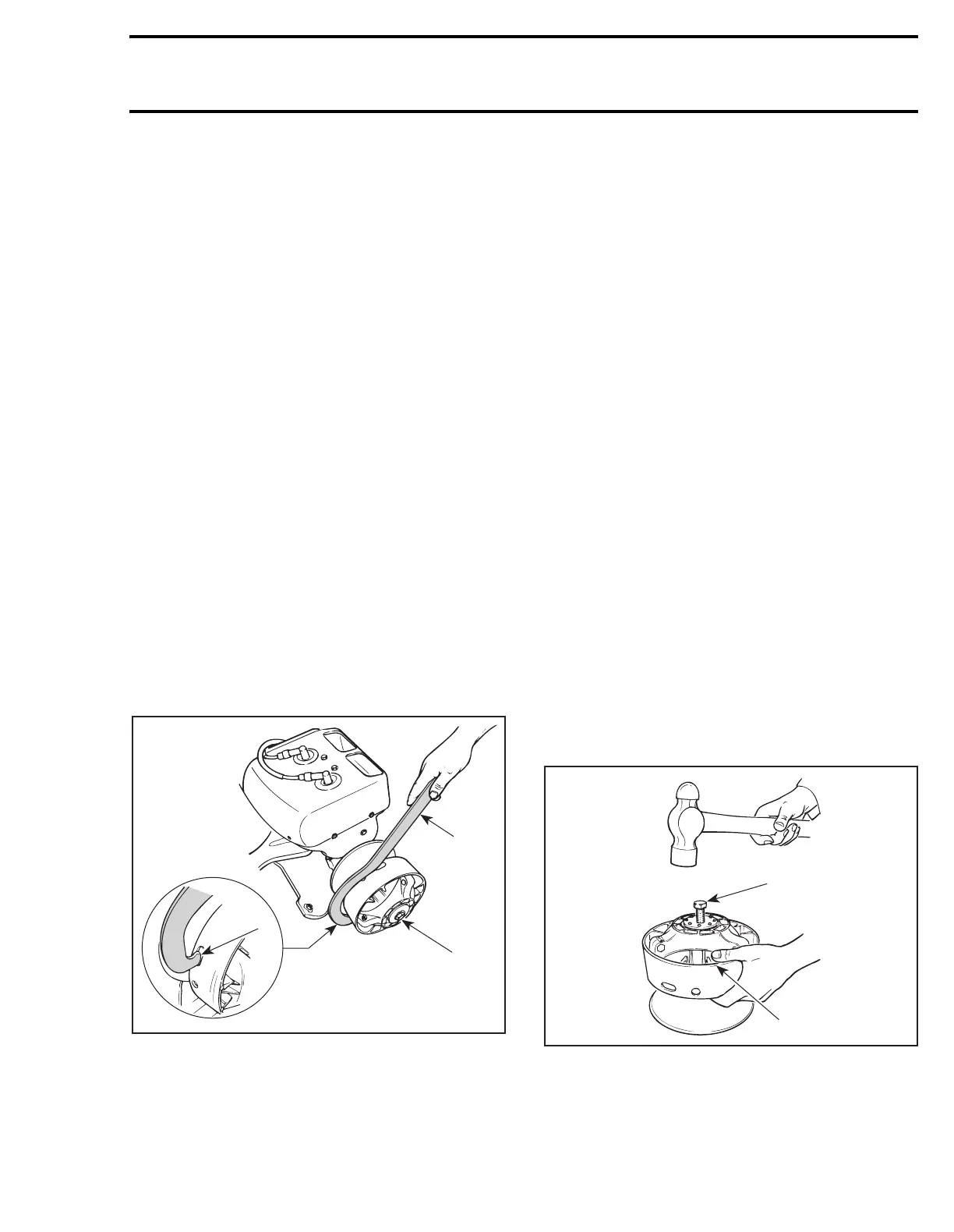

REMOVAL

30,31, Conical Spring Washer and

Screw

Use clutch holder (P / N 529 0064 00).

TYPICAL

1. Retaining screw

2. Insert in any slot

NOTE :

Sliding half can be removed while

fixed half remains on crankshaft.

WARNING : Never use any type of impact

wrench at drive pulley removal and instal-

lation.

Remove retaining screw.

To remove drive pulley ass’y and / or fixed half

from engine, use puller (P / N 529 0079 00).

CAUTION : These pulleys have metric

threads. Do not use imperial threads pull-

er. Always tighten puller by hand to ensure

that the drive pulley have the same type of

threads (metric vs imperial) prior to fully tight-

en.

To Remove Drive Pulley Ass’y :

Retain drive pulley with clutch holder.

Install puller in pulley shaft then tighten.

DISASSEMBLY

1,2, Screw and Ring Gear

CAUTION : Retaining screws must be

heated before disassembly.

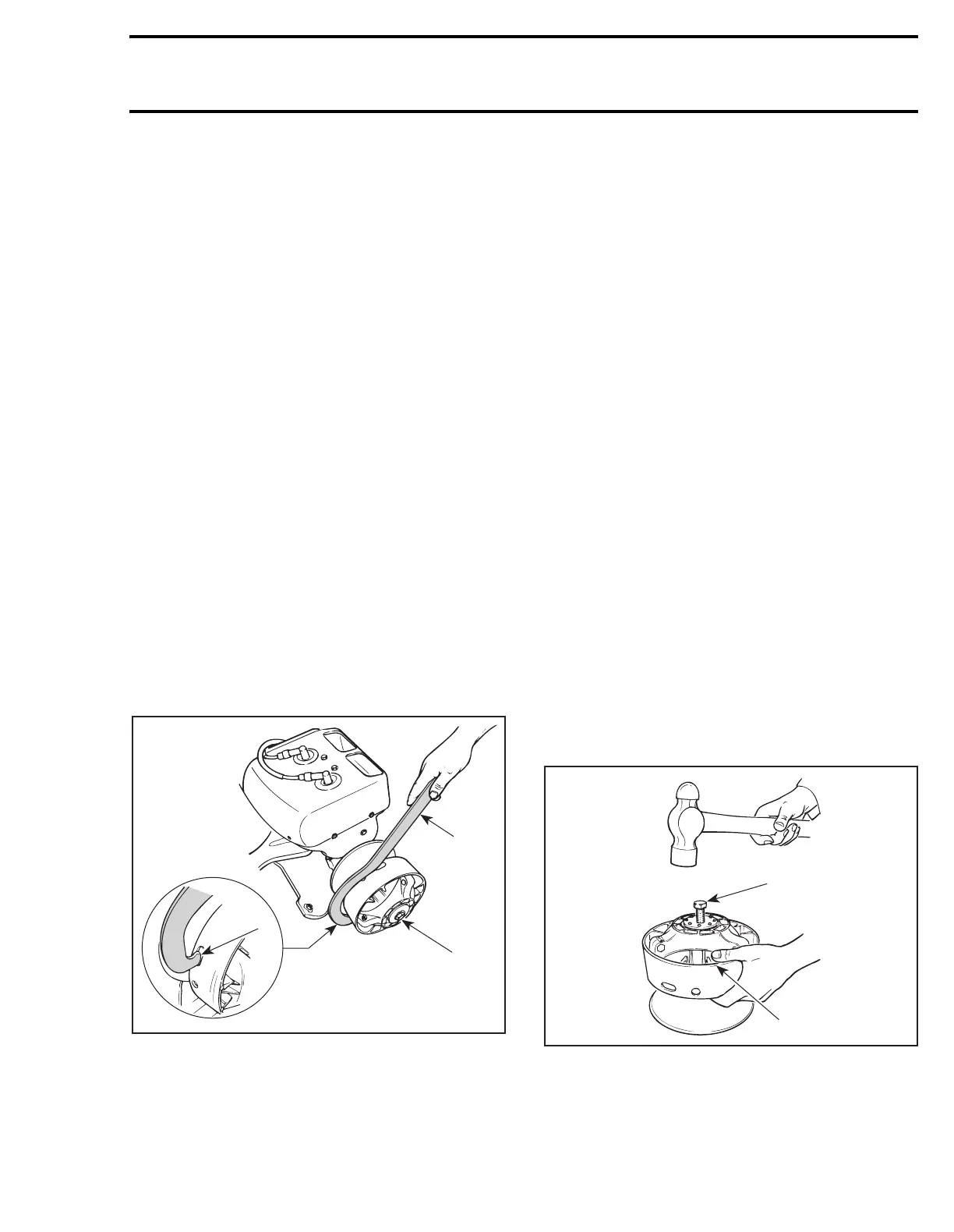

5,6, Fixed and Sliding Half

CAUTION : Do not tap on governor cup.

Screw puller into fixed half shaft about 13 mm (1/2

in). Raise drive pulley and hold it by the sliding half

while knocking on puller head to disengage fixed

half.

1. Puller

2. Holding sliding half

NOTE :

No components marking is required

before disassembling this drive pulley since

it has factory mark and arrows as indexing refer-

ence.

;

A20D06A

2

529 0064 00

1

;

A16D01A

1

2

Loading...

Loading...