Section 04 TRANSMISSION

Sub-Section 04 (DRIVEN PULLEY)

04-04-9

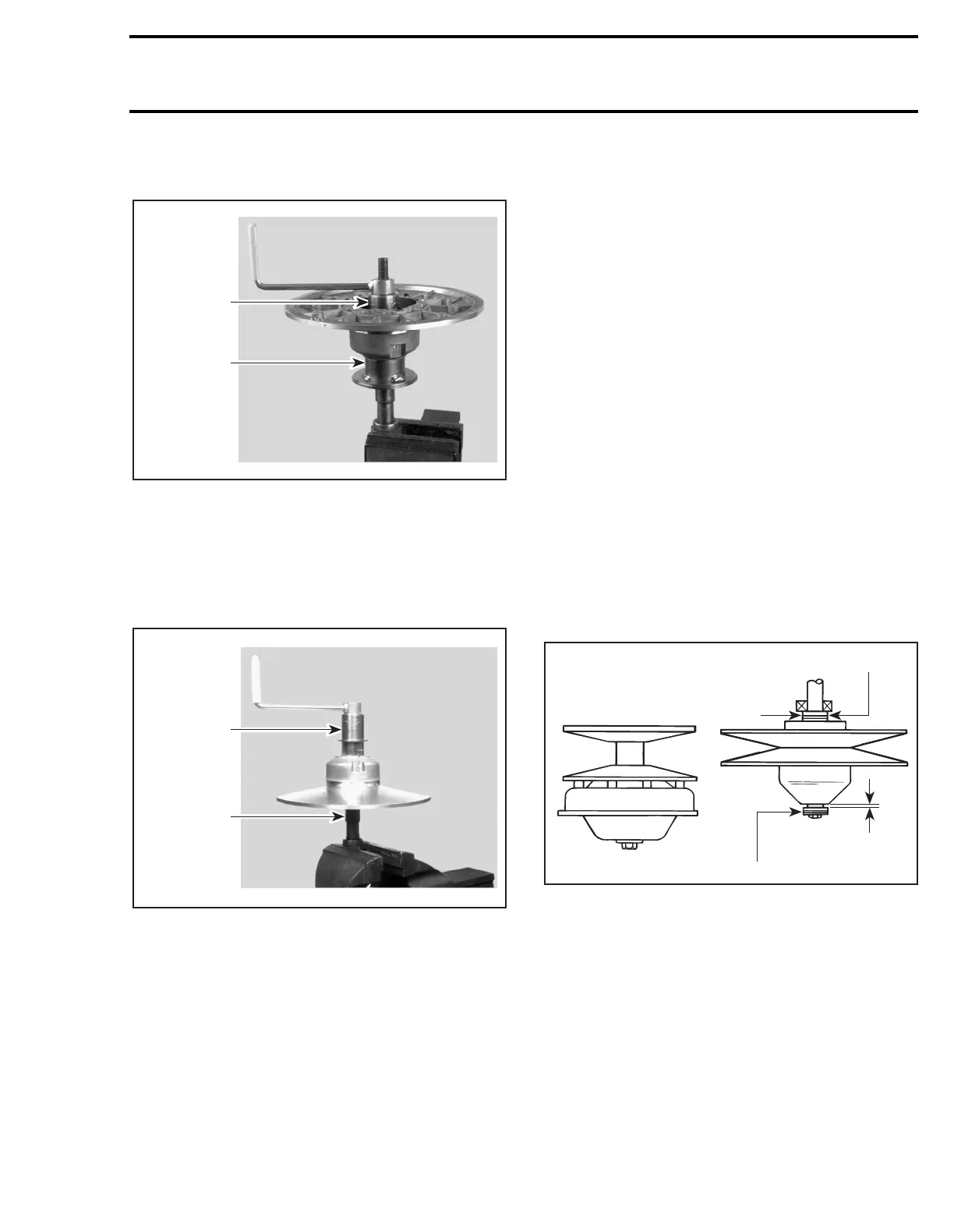

Turn puller handle and sliding half at once to ex-

tract the bushing.

IMPORTANT :

Large bushing retaining screws

and washers must be removed before small

bushing installation.

Coat bushing outside diameter with Loctite 609

(P / N 413 7031 00).

Install bushing as following photo.

ASSEMBLY

4, Cam Slider Shoe

When replacing slider shoes, always install a new

set (3 shoes) to maintain equal pressure on the

cam.

Assemble driven pulley components by reversing

the disassembly procedure.

19, Cam

Coat cam interior with anti-seize lubricant.

INSTALLATION

14,15, Countershaft and Anti-seize

Lubricant

CAUTION : Always apply anti-seize lubri-

cant (P / N 413 7010 00) on the counter-

shaft before final pulley installation.

F-Series and S-Series Only

Should installation procedure be required, refer to

BRAKE 04-06 then look for

Brake Disc

and

Coun-

tershaft Bearing Adjustment

.

Reinstall the pulley on the countershaft by revers-

ing the removal procedure.

All Models

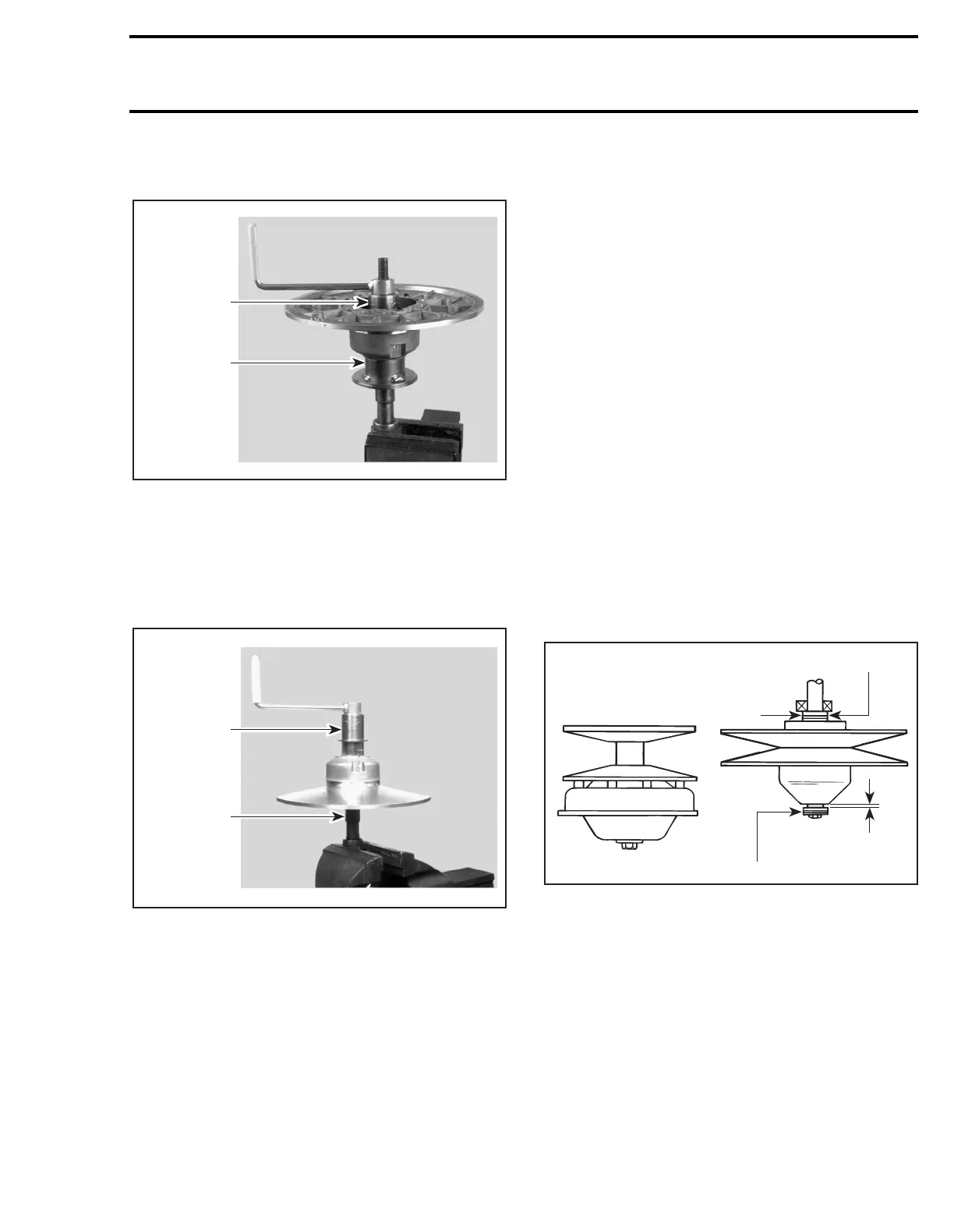

Check end play of driven pulley on countershaft

by pushing pulley towards outer housing so that

the inner shims (P / N 504 1082 00) contact it.

Measure end play at the mounting screw end be-

tween shim(s) and pulley. See illustration.

TYPICAL — TOP VIEW

1. Shim (P / N 504 1082 00) (as required)

2. Contact

A. 0 to 1 mm (0 to 3/64 in)

13, Pulley Retaining Screw

Torque to 25 N•m (18 lbf•ft).

A03D1YA

529 0313 00

529 0312 00

A03D1ZA

529 0313 00

529 0312 00

A16D0IA

1

2

A

1

Loading...

Loading...