Section 04 TRANSMISSION

Sub-Section 04 (DRIVEN PULLEY)

04-04-3

6,9, Sliding Half Bushing and Bushing

To disassemble a worn bushing (small), use a

press and a suitable pusher.

TYPICAL

Remove 3 screws and washers and pry large

bushing out.

INSPECTION

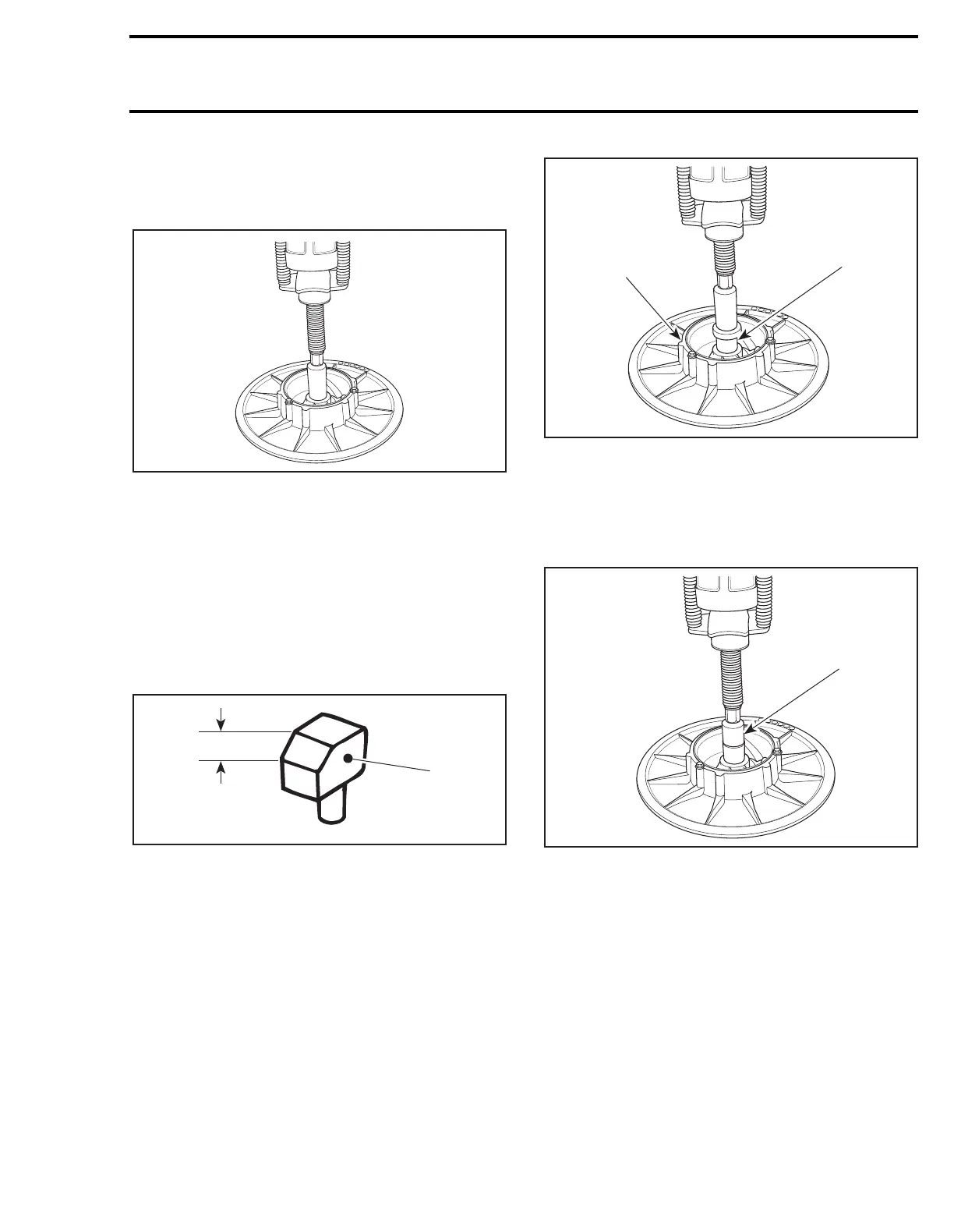

3, Slider Shoe

Check cam slider shoes for wear. Replace when

inside edge of cam slider shoe slope is worn to 1

mm (.039 in) or less.

1. Measure length of slider shoe slope

2. Sliding pulley side

ASSEMBLY

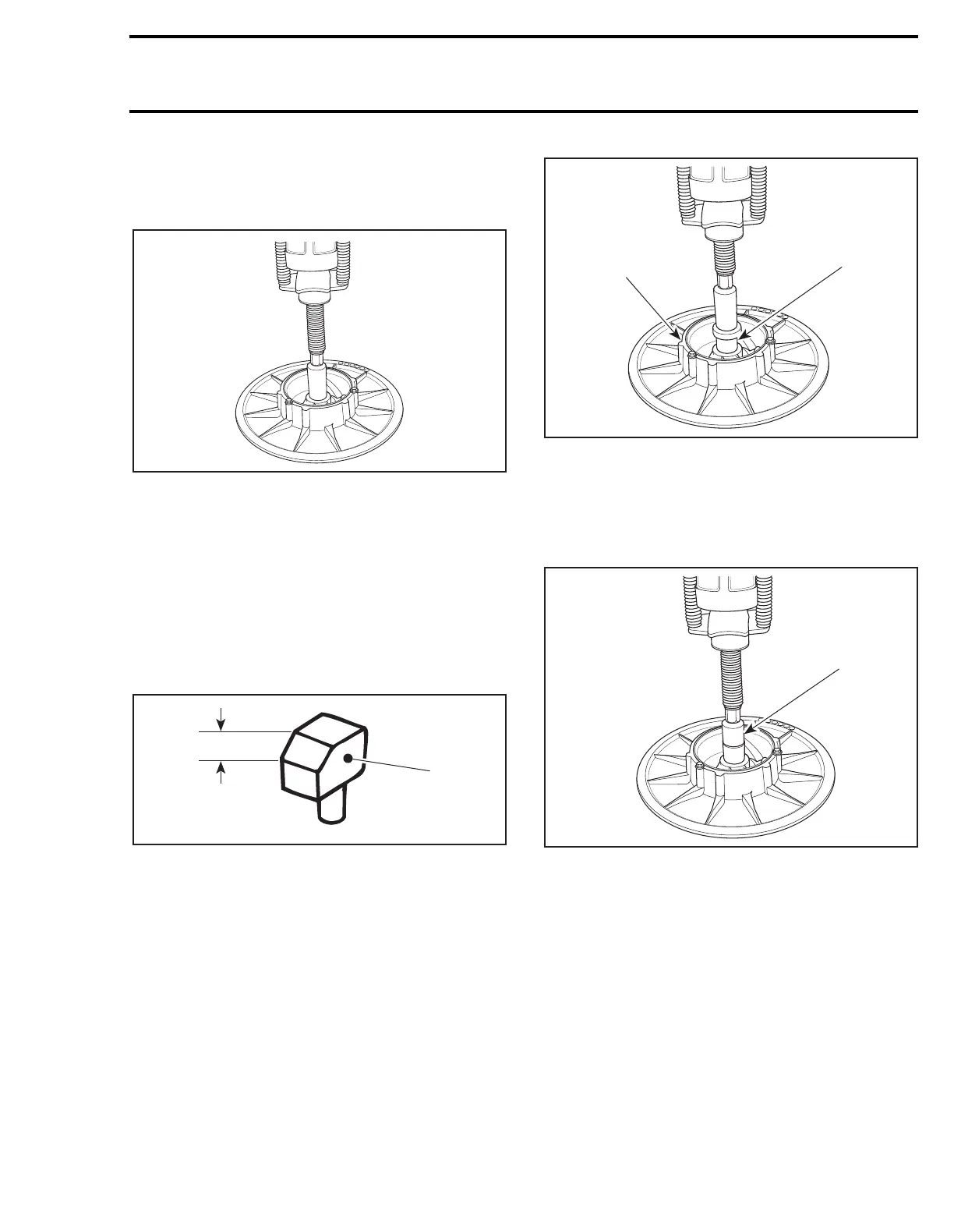

6, Sliding Half Bushing

Clean mounting surfaces with Loctite Safety Sol-

vent. Using a press and a suitable pusher, install

bushing as illustrated.

1. Install bushing from this side of sliding half

2. Bushing

After bushing installation, try fixed half shaft in-

side bushing. If it is too tight, use burnishing bar

(P / N 529 0264 00) then retry. If it is still too tight,

use burnishing bar with oil on it.

8,9, Screw and Bushing

Align notches with screw positions and press

down. Torque screws to 5 N•m (44 lbf•

in

).

3, Slider Shoe

When replacing slider shoes, always install a new

set (3 shoes) to maintain equal pressure on cam.

A25D0KA

A25D0IA

2

1

A25D0LA

2

1

A25D0MA

529 0264 00

Loading...

Loading...