Section 03 ENGINE

Sub-Section 02 (277 ENGINE TYPE)

03-02-8

NOTE :

Engine must be removed from chas-

sis to perform the following procedures.

CLEANING

Discard all oil seals and gaskets.

Clean all metal components in a non-ferrous met-

al cleaner.

DISASSEMBLY

General

To remove drive pulley, refer to DRIVE PULLEY

04-03.

To remove magneto, refer to MAGNETO 03-05.

2,6, Crankcase Half

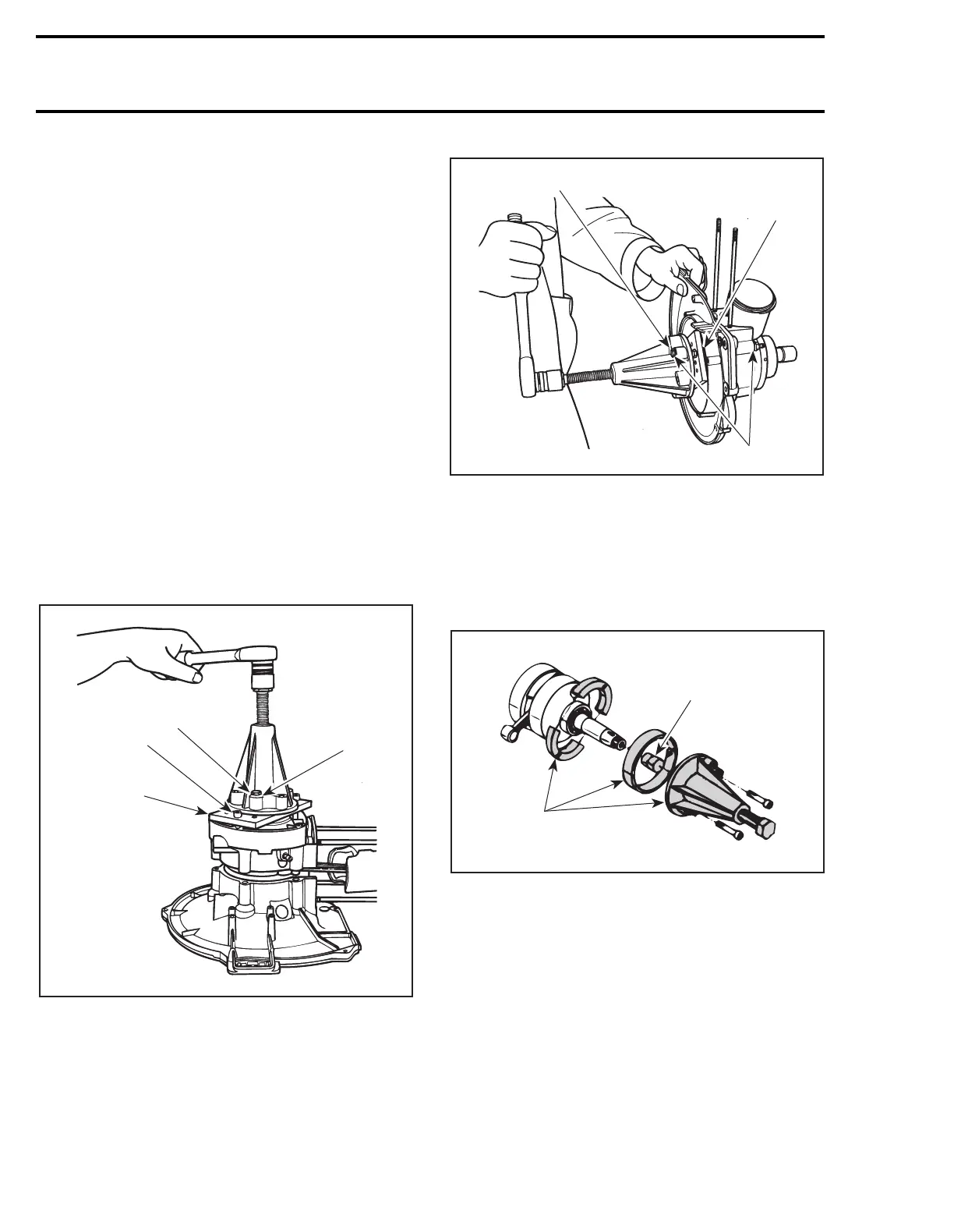

Heat to 110-120°C (230-248°F) all around bearing

seat on PTO side. Install puller (P / N 420 8762 98)

to plate (P / N 529 0249 00) with washer under

screw heads and extract PTO side crankcase half

no. 1

.

1. Plate

2. Flat washer

Heat to 110-120°C (230-248°F) all around bearing

seat on MAG side. Install puller with plate, long

bolts M8 x 110 mm and flat washers. Extract

MAG side crankcase half

no. 2

.

1. Plate

2. Flat washers

To remove seals

nos. 3

and

4

, push from outside

the crankcase towards the inside.

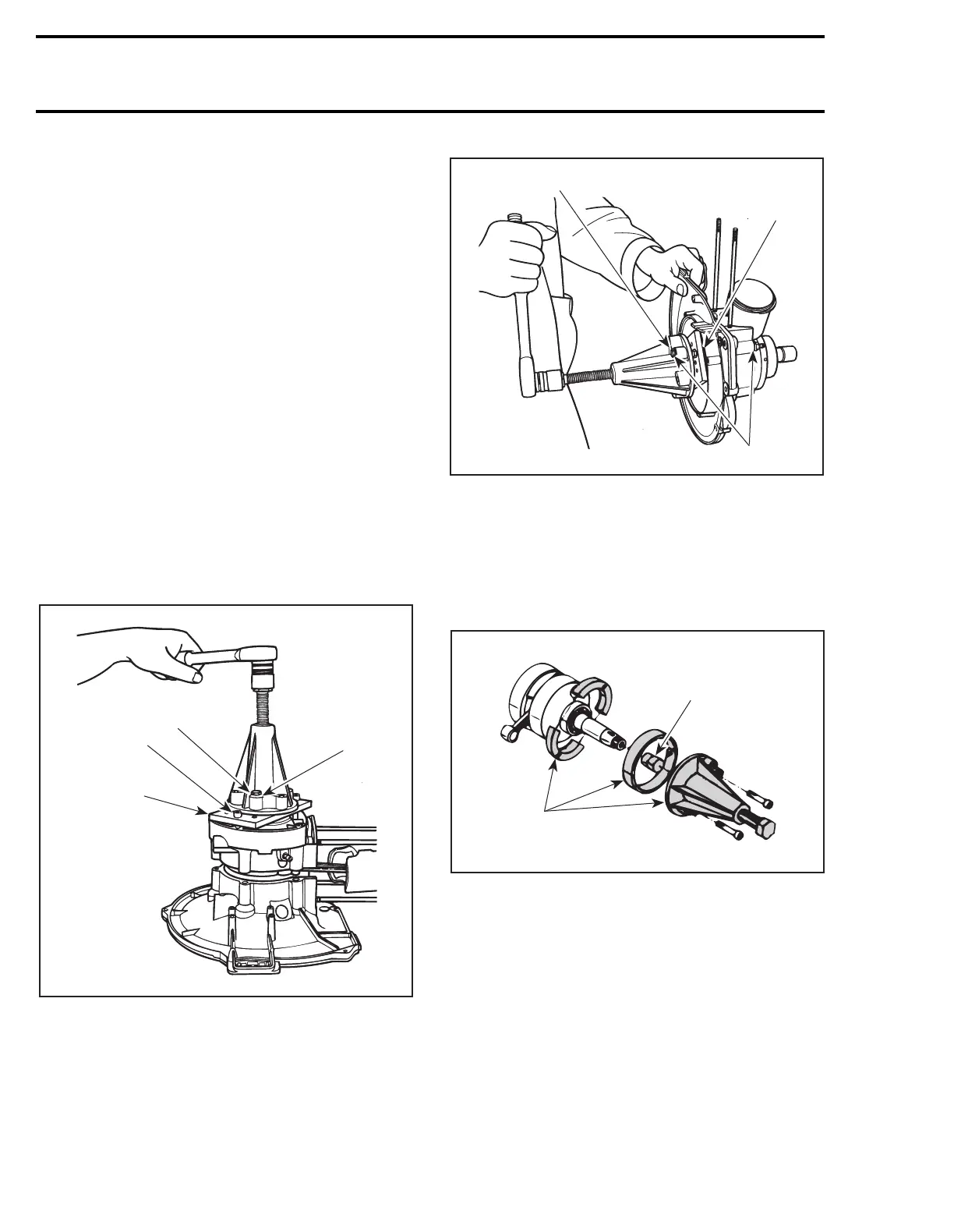

To remove bearings

nos. 5

and

6

from crankshaft

use a protective cap and special puller as illustrat-

ed.

1. Protective cap

2. Special puller

INSPECTION

Refer to ENGINE DIMENSIONS MEASUREMENT

03-04.

ASSEMBLY

Smear anti-seize lubricant (P / N 413 7010 00) on

part of crankshaft where bearing fits.

A05C0GA

1

M8 x 40

2

M8 x 30

A05C0HA

1

M8 x 110 mm

2

1

2

A00B28A

Loading...

Loading...