Section 03 ENGINE

Sub-Section 03 (LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

03-03-8

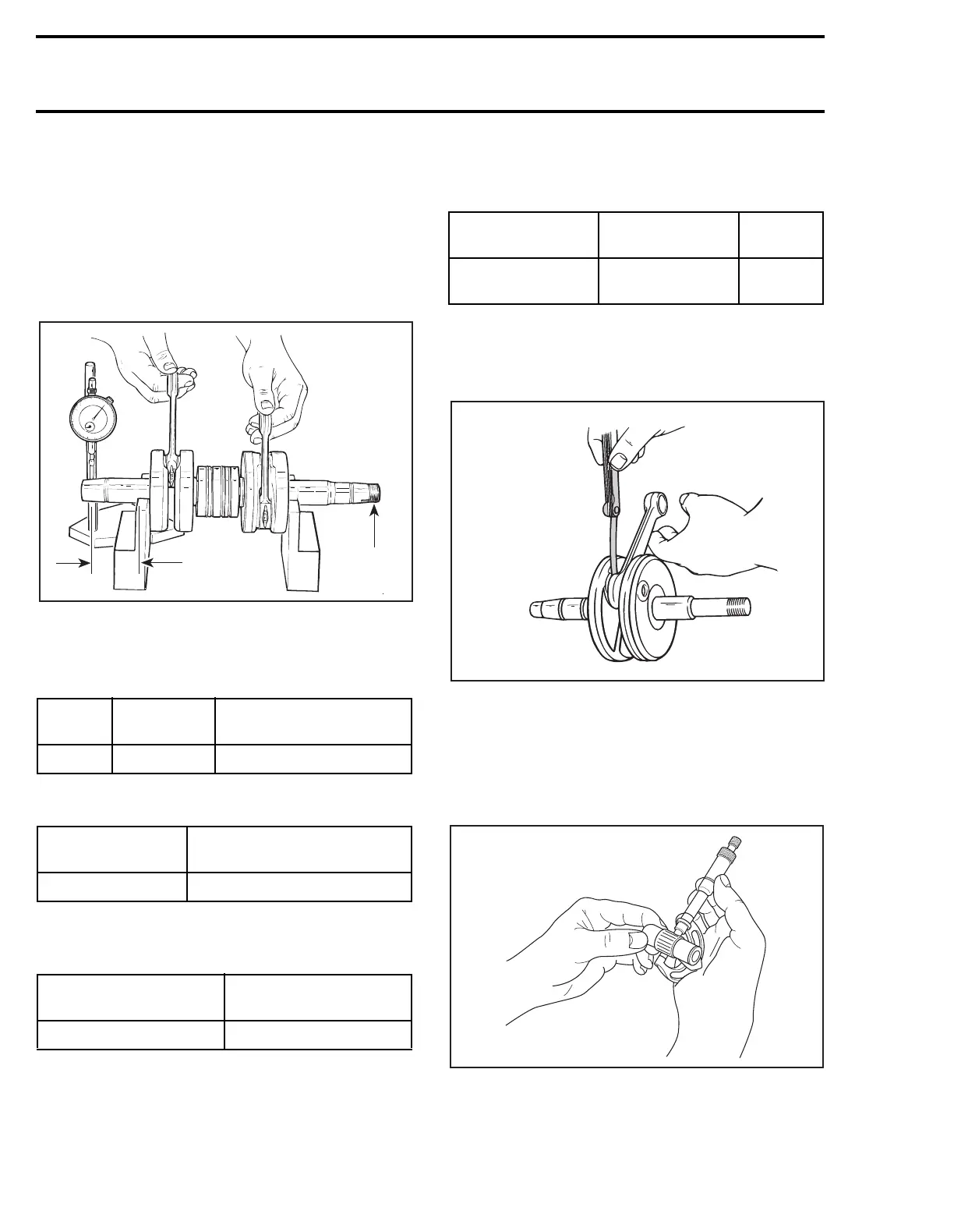

Measuring (on bench)

Once engine is disassembled, check crankshaft

deflection on V-shaped blocks. If deflection ex-

ceeds the specified tolerance, it can be worn

bearings or a bent crankshaft. Remove crankshaft

bearings and check deflection again on V-shaped

blocks to determine the defective part(s). See

measurement A in following illustration.

TYPICAL

1. Measure at mid point between the key and the first thread

A. See table below

Crankshaft Deflection on PTO Side

Crankshaft Deflection on MAG Side

Crankshaft Deflection in Center of

Crankshaft

NOTE:

Crankshaft deflection can not be correctly

measured between centers of a lathe.

If the deflection exceeds the specified tolerance,

crankshaft should be repaired or replaced.

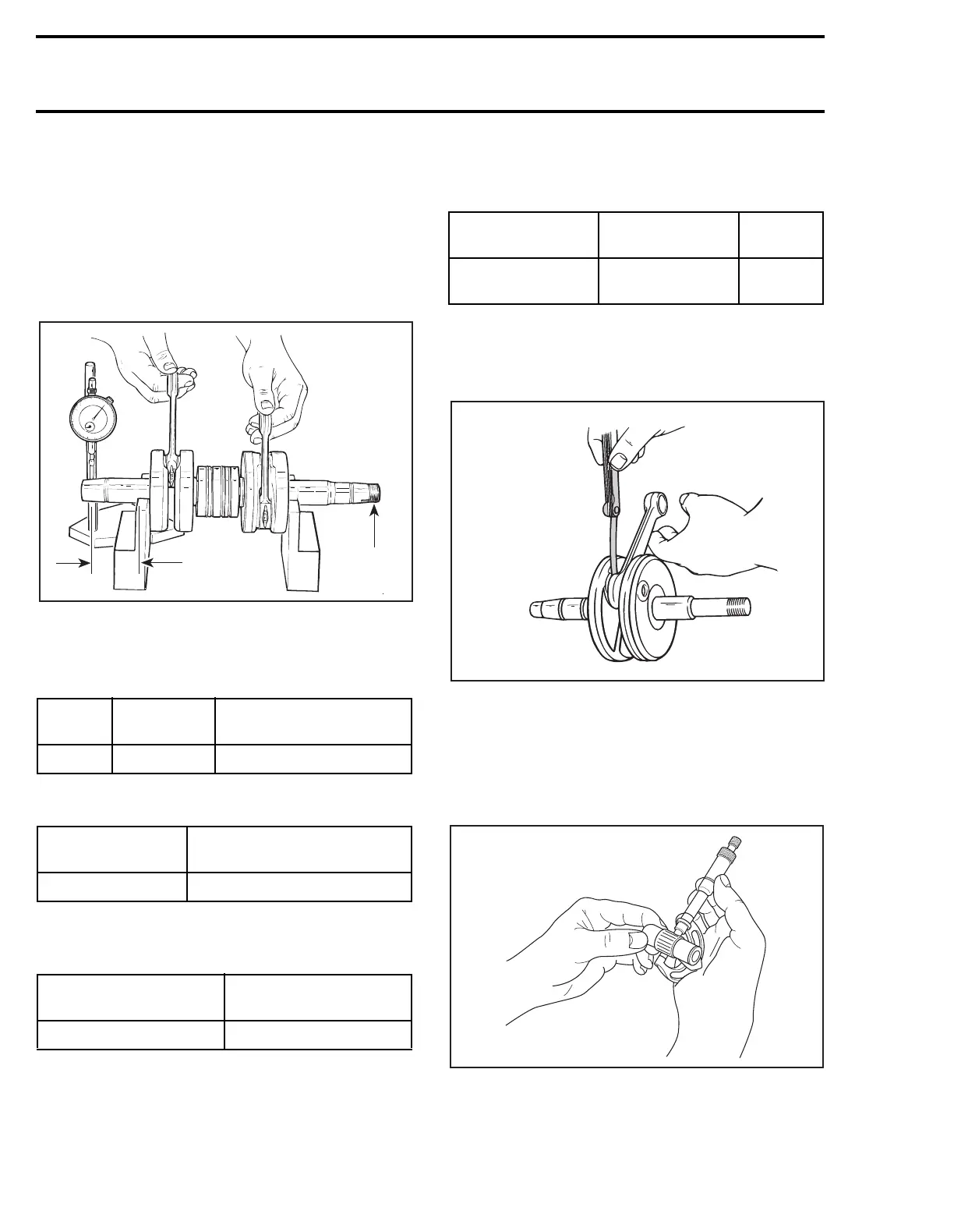

CONNECTING ROD BIG END

AXIAL PLAY

Using a feeler gauge, measure distance between

thrust washer and crankshaft counterweight. If

the distance exceeds specified tolerance, repair or

replace the crankshaft.

TYPICAL

CONNECTING ROD/PISTON PIN

CLEARANCE

Measure piston pin with its needle bearing. Com-

pare to inside diameter of connecting rod.

ENGINE

TYPE

DISTANCE A

mm (in)

MAXIMUM ON PTO SIDE

mm (in)

All 94.5 (3.720) 0.03 (.0012)

ENGINE TYPE

MAXIMUM ON MAG SIDE

mm (in)

All 0.05 (.002)

ENGINE TYPE

MAXIMUM IN CENTER

OF CRANKSHAFT

All 0.08 mm (.0031 in)

A

A01C0RA

1

ENGINE

TYPE

NEW PARTS

MIN. – MAX.

WEAR

LIMIT

All

0.40 – 0.75 mm

(.016 – .029 in)

1.20 mm

(.047 in)

A01C0SA

A01C3GA

Loading...

Loading...