Section 03 ENGINE

Sub-Section 04 (LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

03-04-4

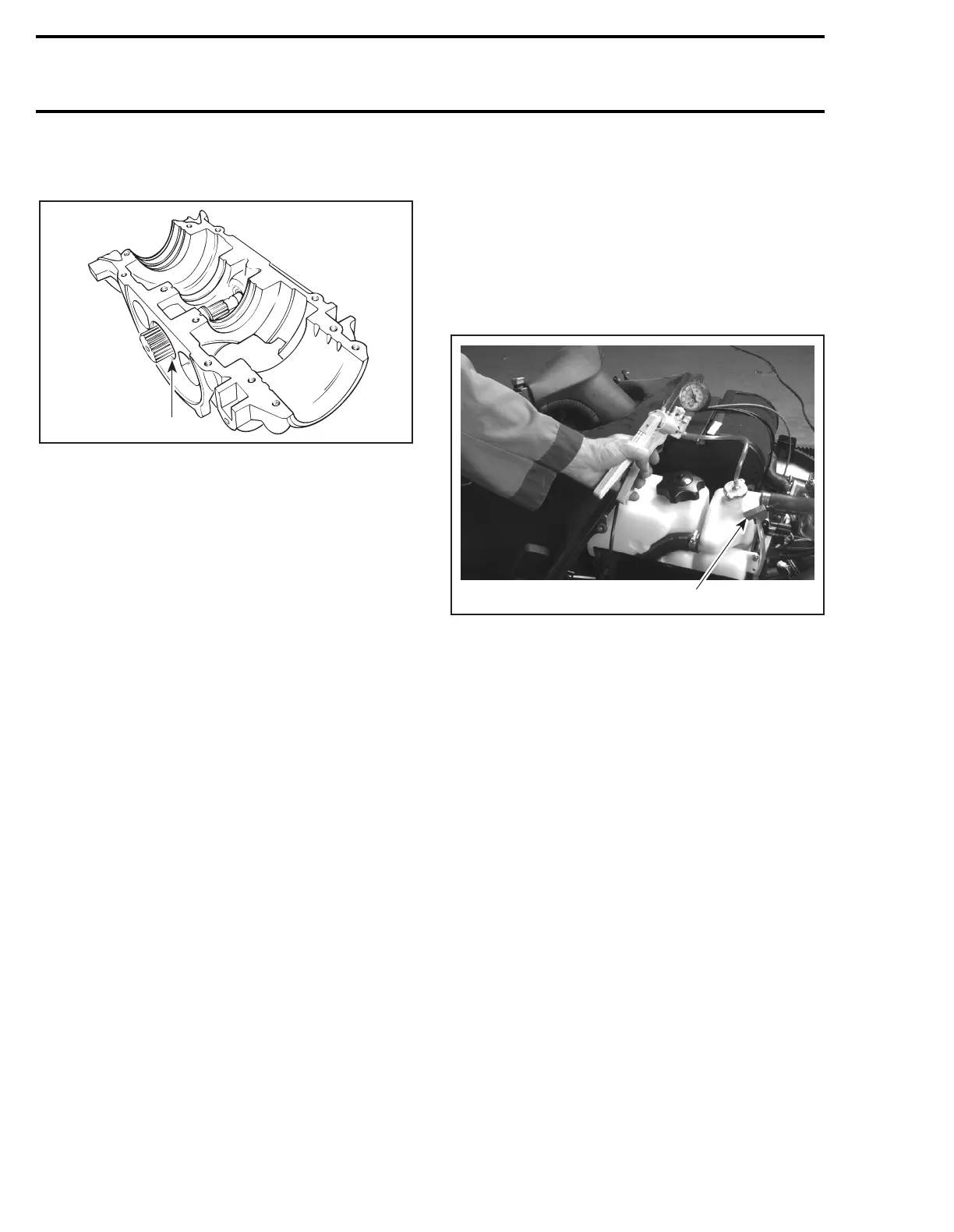

4. Remove rotary valve cover and check for leak

of rotary valve seal with soapy water.

1. Seal

5. If leak still persists, it indicates a defective cast-

ing somewhere in engine.

Disassemble engine and carefully check for de-

fects in castings. Pay attention to tapped holes

which may go through engine sealed area and

thus leading to leakage.

FINALIZING REASSEMBLY

After reassembling engine, always recheck for

leakage.

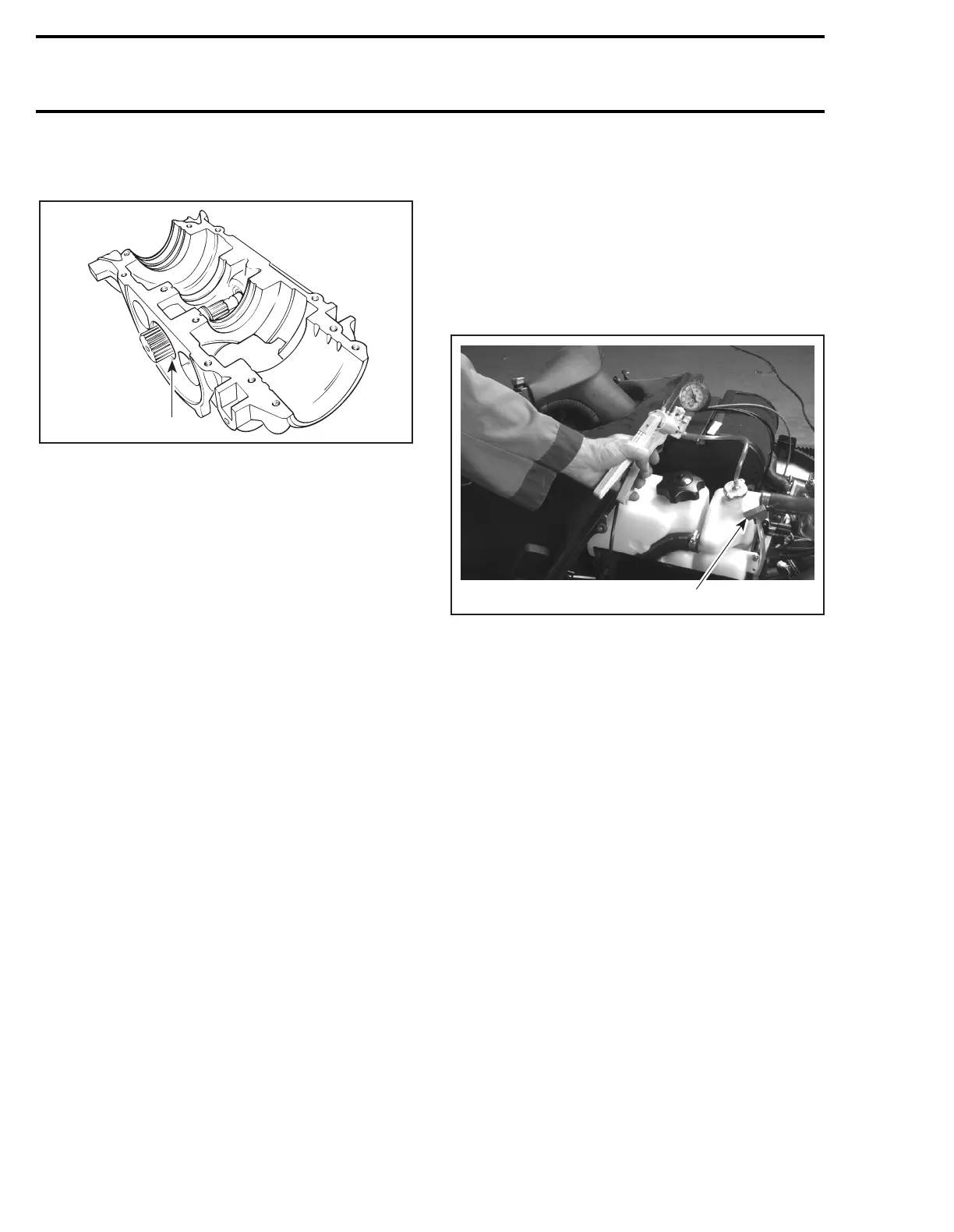

COOLING SYSTEM LEAK TEST

Install special plug (radiator cap) (P/N 529 0214

00) and hose pincher (P/N 529 0099 00) on over-

flow hose. Pressurize all system through coolant

reservoir to 15 PSI.

Check all hoses and cylinder/base for coolant

leaks. Spray a soap/water solution and look for

presence of air bubbles.

TYPICAL

A01D1BB

1

A01B4AA

529 0099 00

Loading...

Loading...