Section 04 TRANSMISSION

Sub-Section 06 (BRAKE)

04-06-7

Apply anti-seize lubricant (P / N 413 7010 00) on

shaft and check that disc slides freely.

The disc hub exceeds the disc more from one

side than from the other. Install disc with the long-

er exceeding portion toward driven pulley.

Push O-rings inside disc hub.

Countershaft Bearing Adjustment

S-Series

Insert countershaft (with brake disc) from chain-

case side through countershaft support (driven

pulley side), then insert into chaincase.

Install countershaft bearing

no. 19

and ensure

that countershaft is properly aligned, then tighten

3 retaining screws.

NOTE :

A misaligned countershaft will result

in difficulty to center the bearing in its sup-

port.

Refer to DRIVE AXLE 06-04 then look

Chaincase

Perpendicularity Adjustment.

Torque castellated nut of upper sprocket to 53

N•m (39 lbf•ft).

CAUTION : Upper sprocket castellated nut

must be tightened

before

adjusting bearing

collar.

Slide collar

no. 18

towards bearing and turn, by

hand, to engage the eccentric. This should require

about a quarter turn.

Turn collar in direction of countershaft rotation un-

til collar and inner race lock together.

Insert a punch into collar hole and strike sharply in

the same direction to lock firmly.

Apply Loctite 242 (P / N 413 7030 00) on set

screw threads, then tighten.

Close chaincase referring to CHAINCASE 04-07.

1,11,12, Locking Tab, Outer Caliper

and Nut

S-Series

Install caliper retaining bolts.

Assemble outer caliper. Install locking tab then

nuts. Torque nuts to 24 N•m (18 lbf•ft). Bend lock-

ing tab over a flat of each nut.

5,10, Brake Cable and Nut

Insert brake cable into upper hole in brake lever

and caliper. Install nut and tighten until a few

threads exceed.

WARNING : At least 3 threads must ex-

ceed the elastic stop nut.

ADJUSTMENT

Brake

Models with Mechanical Brake

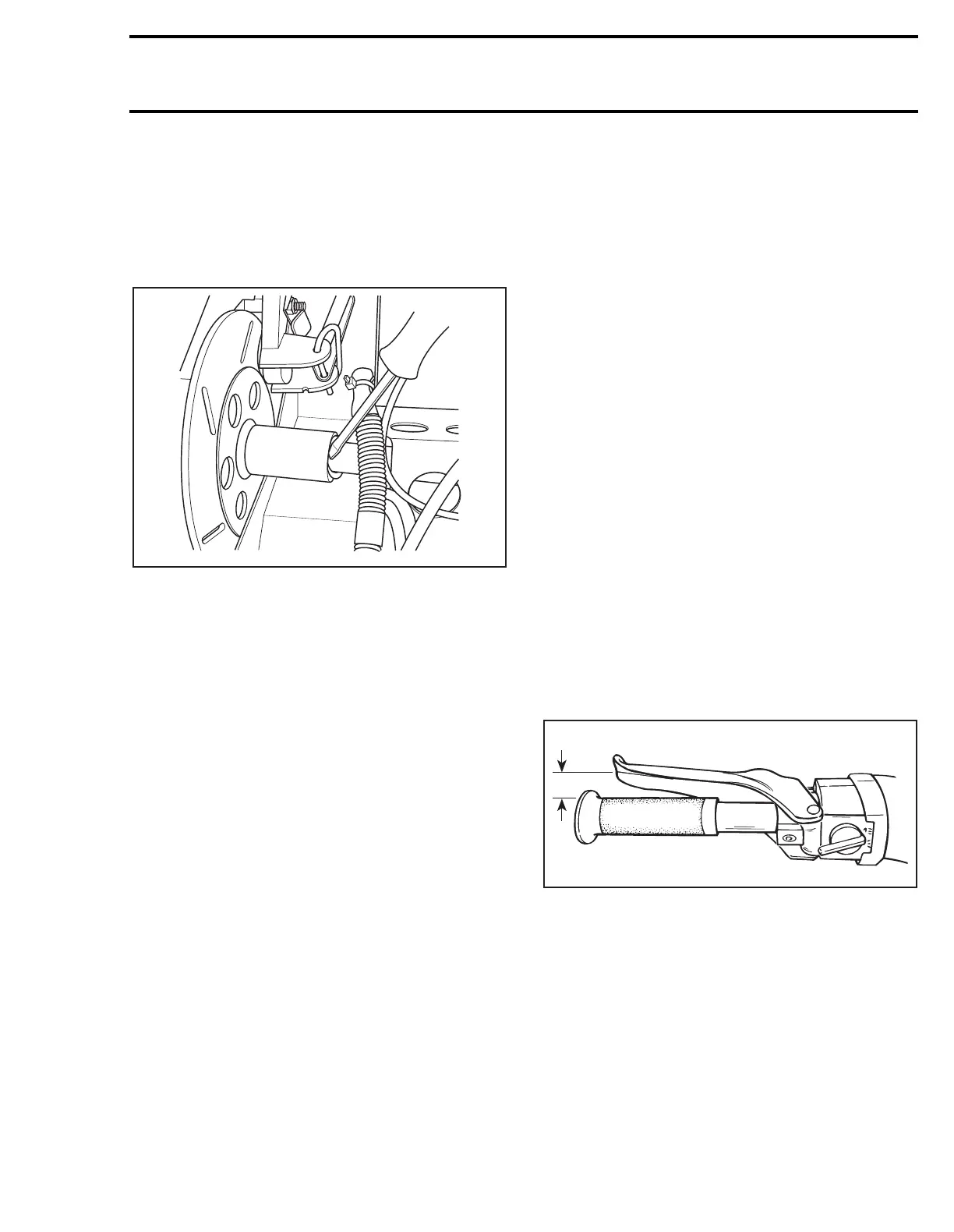

Fully depress brake handle several times to obtain

13 mm (1/2 in) between brake handle and handle-

bar grip when brake is fully applied.

A. 13 mm (1/2 in)

Should this adjustment be unattainable, retighten

nut

no. 10

as needed.

Models with Hydraulic Brake

Change brake fluid once a year.

Bleed brake system as follows :

Keep sufficient DOT 4 (DOT 3 for normal use)

brake fluid in reservoir at all times.

CAUTION : Use only DOT 4 brake fluid for

heavy duty or racing applications.

A03D13A

;

A08G02A

A

Loading...

Loading...