Section 04 TRANSMISSION

Sub-Section 04 (DRIVEN PULLEY)

04-04-10

ADJUSTMENT

Refer to PULLEY DISTANCE AND ALIGNMENT

04-05 to adjust pulley distance. Adjust drive belt

height between pulley halves to obtain specified

belt deflection.

5, Spring

Spring Torsional Pre-Load

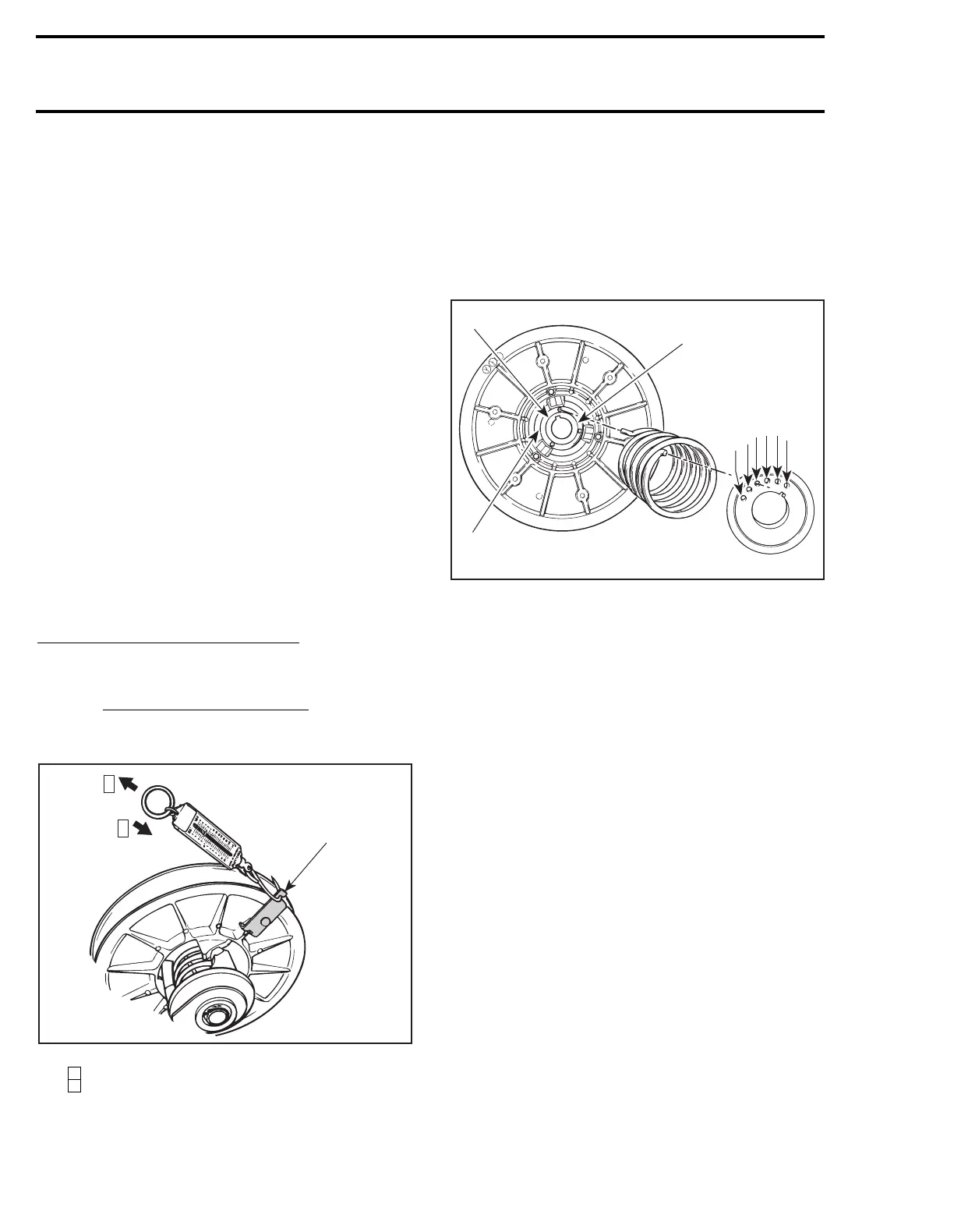

To check spring pre-load adjustment, use spring

scale hook (P / N 529 0065 00) and a spring scale.

Remove drive belt.

Install the hook on the sliding half. Preventing

fixed half from turning, pull sliding half with the

spring scale perpendicularly with pulley axle.

Take 1

st

measurement when sliding half begins to

turn. Rotate sliding half to 10 mm (3/8 in) of rota-

tion. Hold fish scale at this position. Slowly re-

lease tension from fish scale and take 2

nd

measurement when sliding half begins to return.

Spring pre-load is the average measurement be-

tween these 2.

TYPICAL

Step : 1

st

measurement

Step : 2

nd

measurement

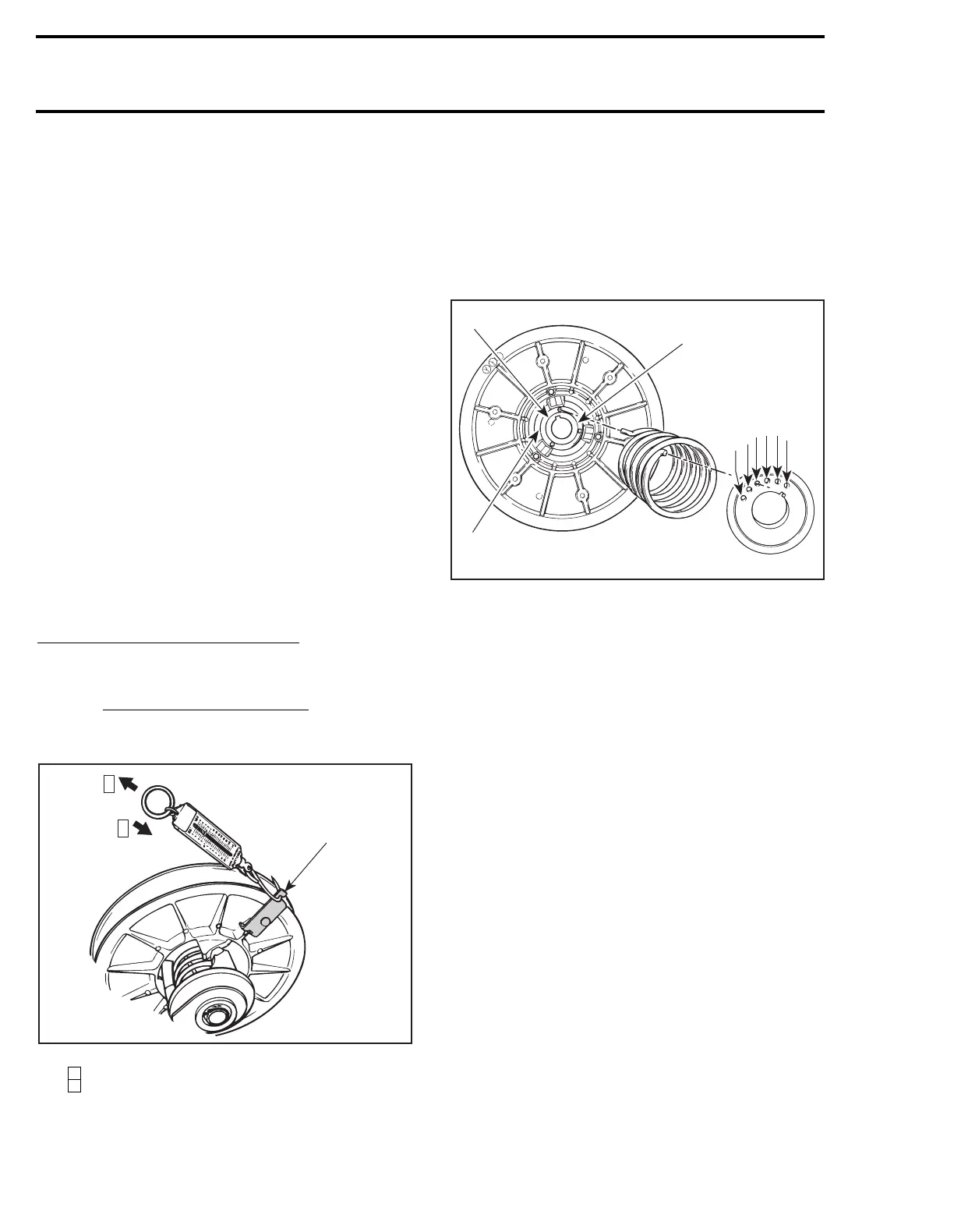

To adjust spring pre-load, relocate spring end in

cam, moving it clockwise to increase the pre-load

and counterclockwise to decrease it. Refer to

TECHNICAL DATA 09-03.

NOTE :

If spring pre-load can not be adjust-

ed, try to relocate the other end of spring in

sliding pulley (holes A, B, C).

Letters and numbers shown in illustration are actual letters and

numbers embossed on parts

NOTE :

Always recheck torsional pre-load

after adjusting.

Pulley Alignment and Drive Belt

Deflection

Refer to PULLEY DISTANCE AND ALIGNMENT

04-05 and DRIVE BELT 04-02 to perform adjust-

ments.

CAUTION : Drive belt and pulley adjustments

must always be checked whenever pulleys

have been removed, replaced or disassembled.

3, Outer Cam

Make sure to install proper cam. Refer to TECHNI-

CAL DATA 09-03.

Cam angle is identified on cam.

1

st

measurement

(when opening)

+

2

nd

measurement

(when closing)

=

Spring

pre-load

2

Example :

3.8 kg (8.4 lb)

(when opening)

+

3.4 kg (7.5 lb)

(when closing)

=

3.6 kg (8 lb)

Actual

spring

pre-load

2

529 0065 00

A01B18A

1

2

1

2

'

A18C0AA

32

1

4

5

6

A

C

B

Loading...

Loading...