Section 03 ENGINE

Sub-Section 02 (277 ENGINE TYPE)

03-02-9

Prior to installation, place bearings into an oil con-

tainer and heat the oil to 75°C (167°F) for 5 to 10

min. This will expand bearings and ease installa-

tion.

Install bearings with groove outward.

NOTE :

Crankshaft end play requires adjust-

ment only when crankshaft and / or crank-

case is replaced. Prior to magneto side bearing

installation, determine crankshaft end play and in-

stall required shim(s) on crankshaft extension. For

the crankshaft end play adjustment procedure, re-

fer to LEAK TEST AND ENGINE DIMENSION

MEASUREMENT 03-04.

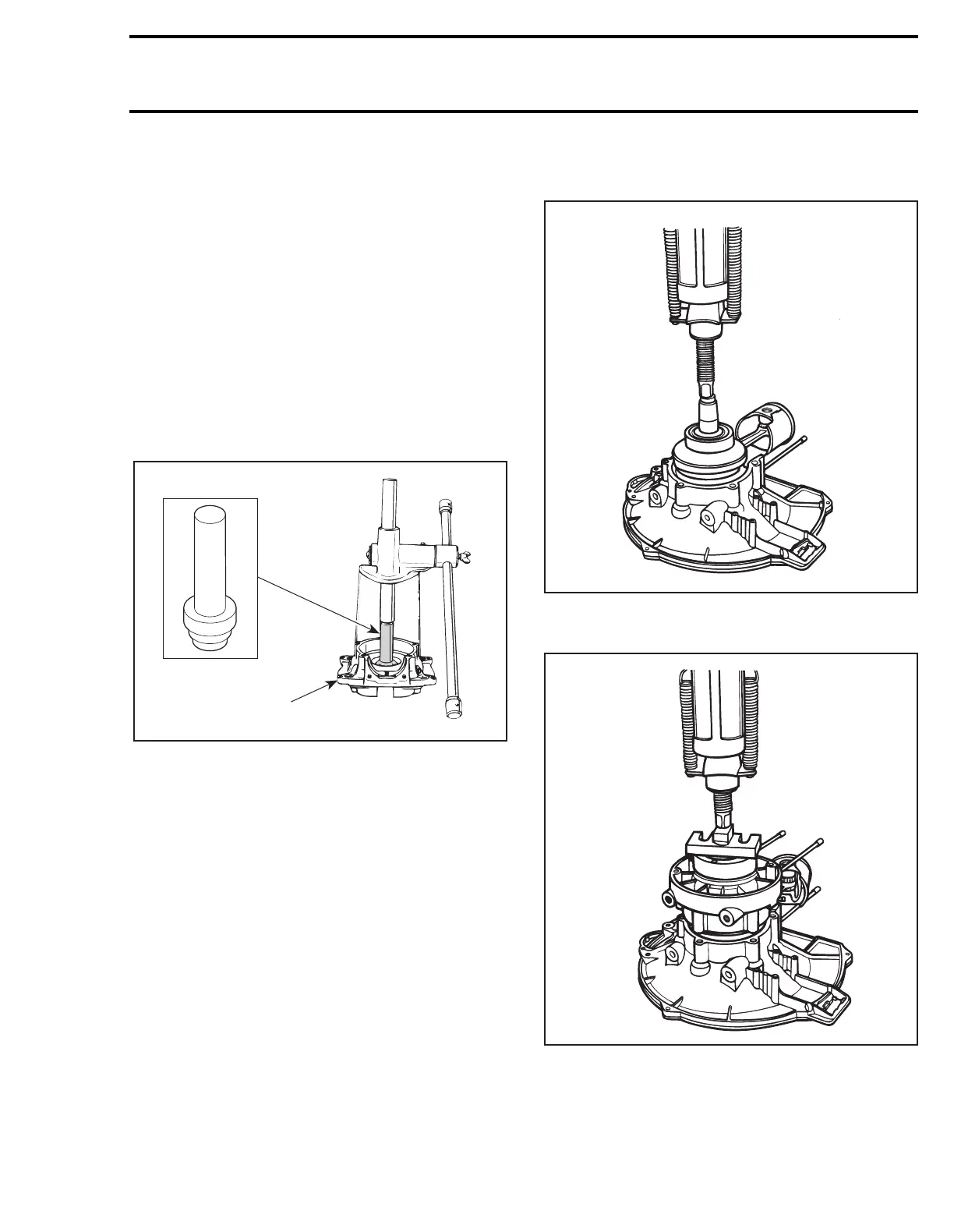

To install new seal

nos. 3

and

4

into crankcase

use oil seal pusher (P / N 420 9779 20).

1. Crankcase half

Prior to crankcase adjoining, install a protector

sleeve on each crankshaft extension to prevent oil

seal damage. Apply a light coat of lithium grease

on seal lip. Spray some new injection oil on all

moving parts of the crankshaft.

Install crankshaft seals with pusher (P / N 420

2778 75) for MAG side seal

no. 4

and (P / N 420

8766 60) for PTO side seal

no. 3

.

CAUTION : To ensure appropriate crank-

shaft bearing lubrication, seal outer sur-

face must be pressed on seal crankcase

shoulder.

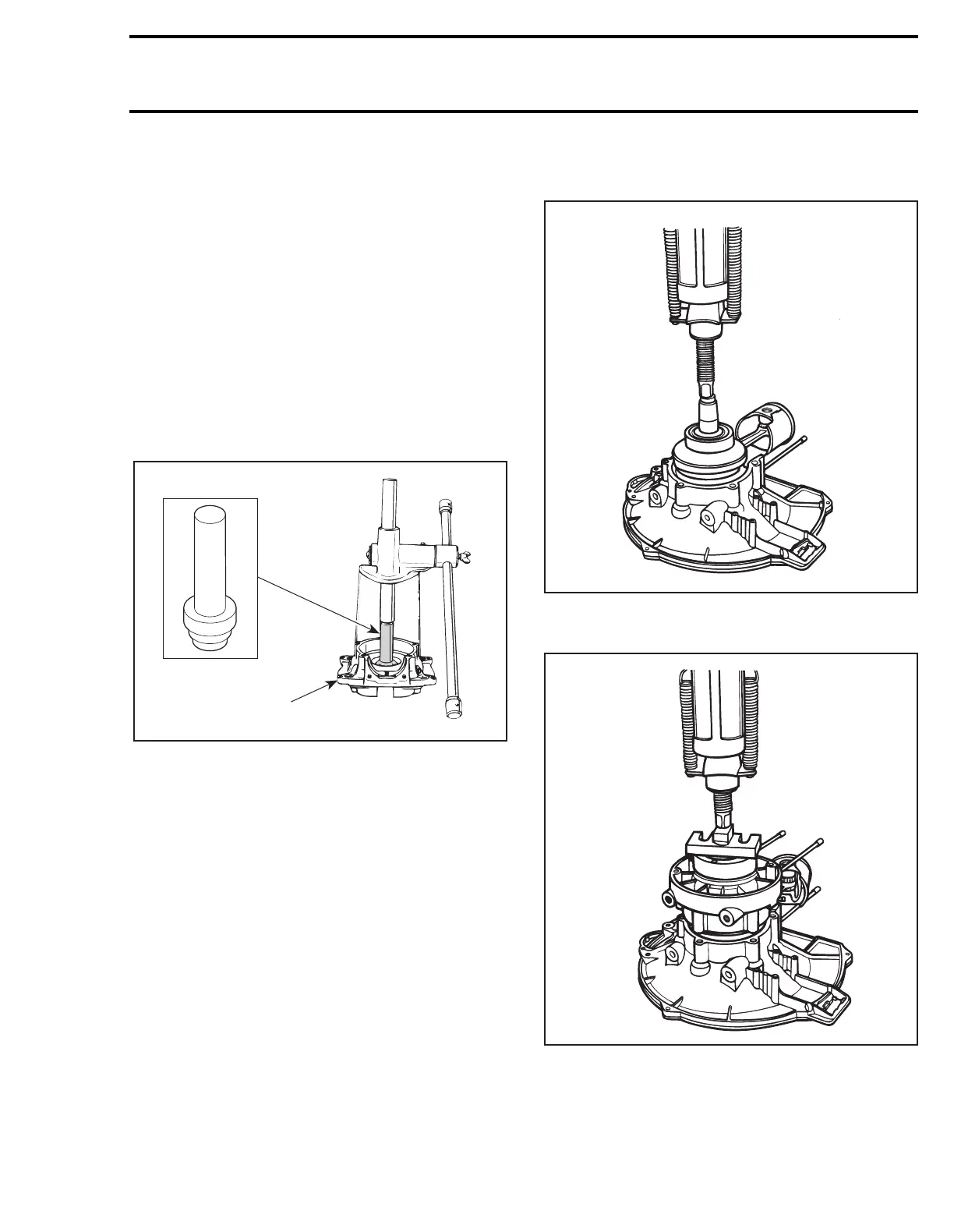

Using a press, install crankshaft into MAG side

crankcase half.

Press down PTO side crankcase half onto crank-

shaft using appropriate spacer(s).

'

A00C3ZA

420 9779 20

1

A05C0IA

A05C0JA

Loading...

Loading...