Section 03 ENGINE

Sub-Section 04 (LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

03-04-9

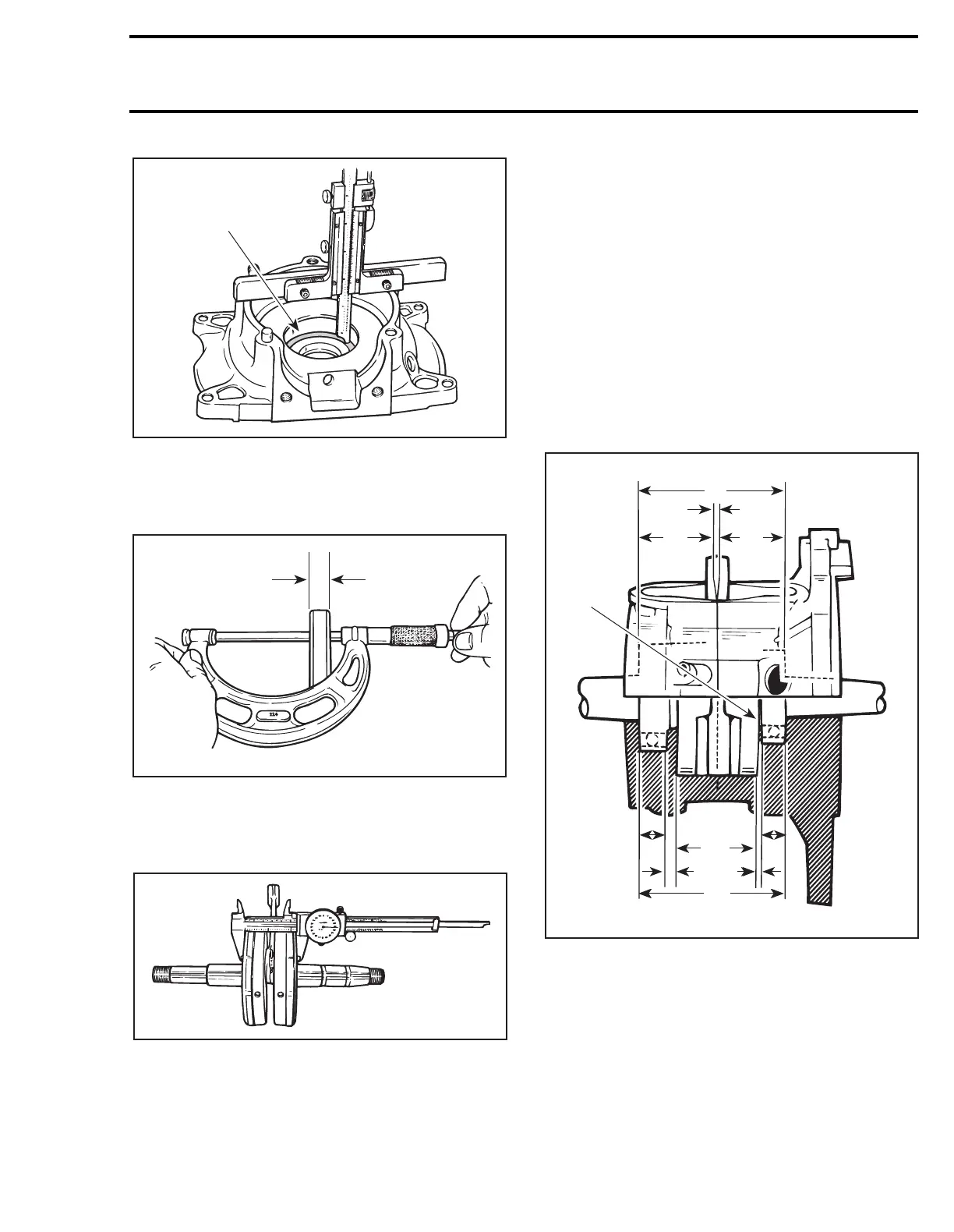

MEASURING M

1

AND M

2

1. Bearing seat

b. Measure the thickness of each bearing (M

4

and

M

5

).

MEASURING M

4

AND M

5

1. Bearing thickness

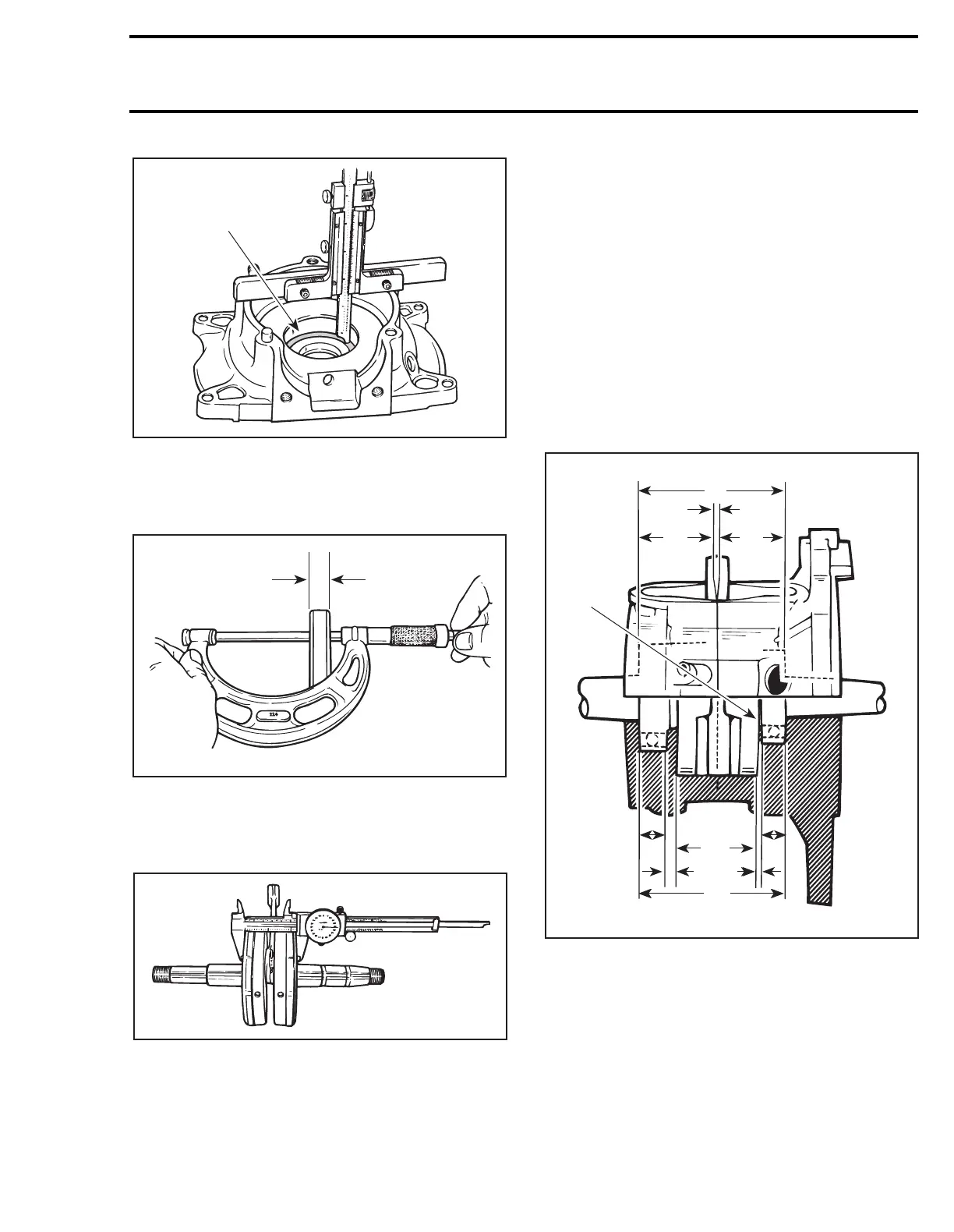

c. Measure distance between bearing shoulders

on crankshaft (M

6

).

MEASURING M

6

d. Measure the distance ring (M

7

) and adjustment

shims thickness (M

8

).

Add these measure-

ments to obtain dimension B.

e. From dimension A, subtract dimension B.

The result is the actual crankshaft end-play that

must be within specification.

If the result is over specification, add adjustment

shim(s) to reach this specification.

If the result is under specification, remove adjust-

ment shim(s) to reach this specification.

To Summarize

A

= M

1

+ M

2

+ M

3

B

= M

4

+ M

5

+ M

6

+ M

7

+ M

8

A – B =

Actual end-play that must be within spec-

ification.

M

8

is the dimension that must be adjusted to ob-

tain the specified crankshaft end-play.

1. End-play is adjusted with shims

2. PTO

3. MAG

377, 443, 503 Engine Types

End-play is not adjustable but it should be be-

tween 0.10 – 0.30 mm (.004 – .012 in).

A01C0TA

1

A01C0UA

1

A02C0LA

A

M

3

M

2

M

1

32

1

M

4

M

5

M

6

M

7

M

8

B

A01C0WA

Loading...

Loading...