Section 03 ENGINE

Sub-Section 02 (277 ENGINE TYPE)

03-02-6

When installing new needle bearing, insert nee-

dles with thrust washers. Instead of expansion

sleeve, needles are held in place by 2 inner plastic

cage halves.

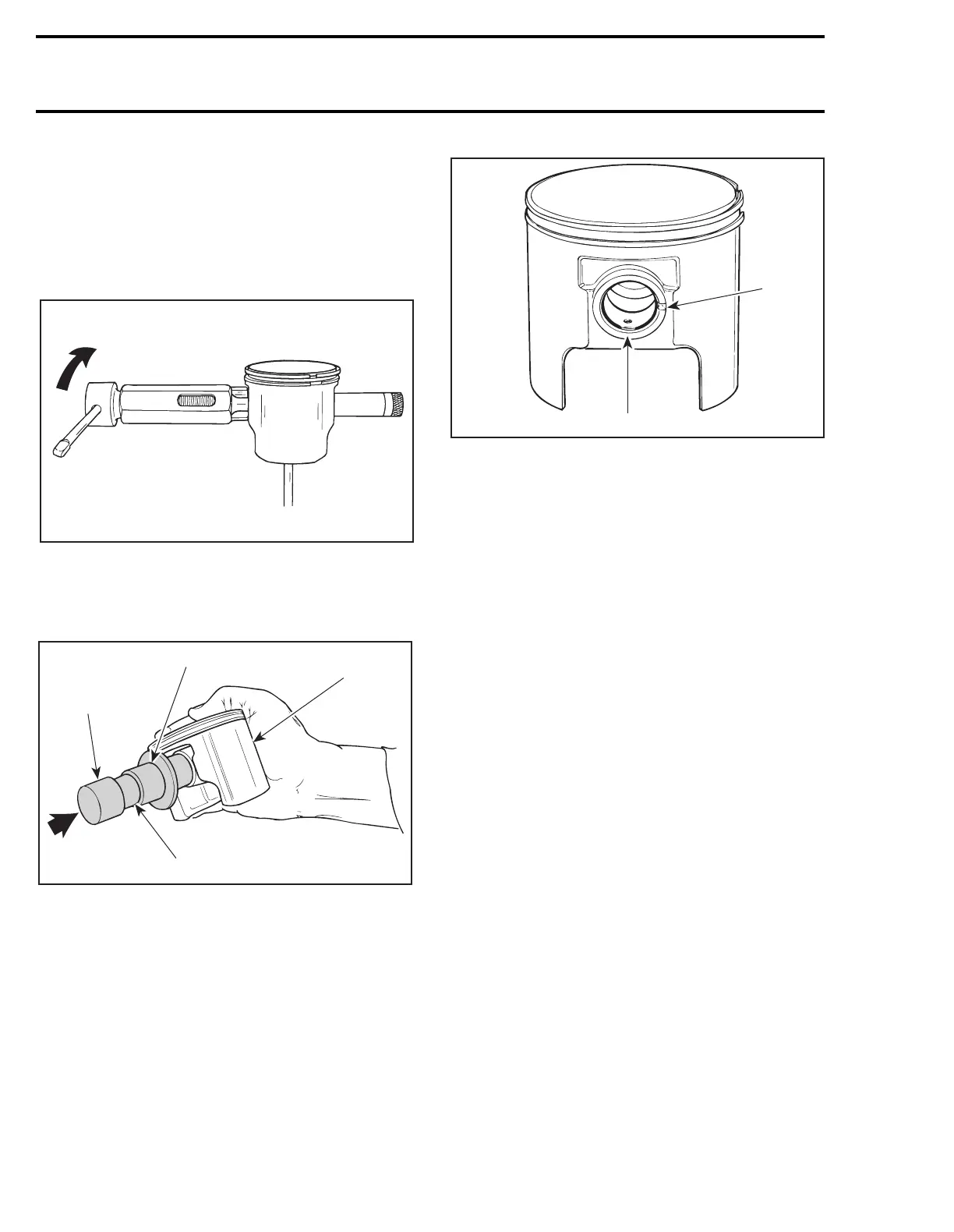

Use piston pin puller (P / N 529 0210 00) to insert

piston pin. Plastic halves should come off piston.

If not, pull them using a long nose pliers.

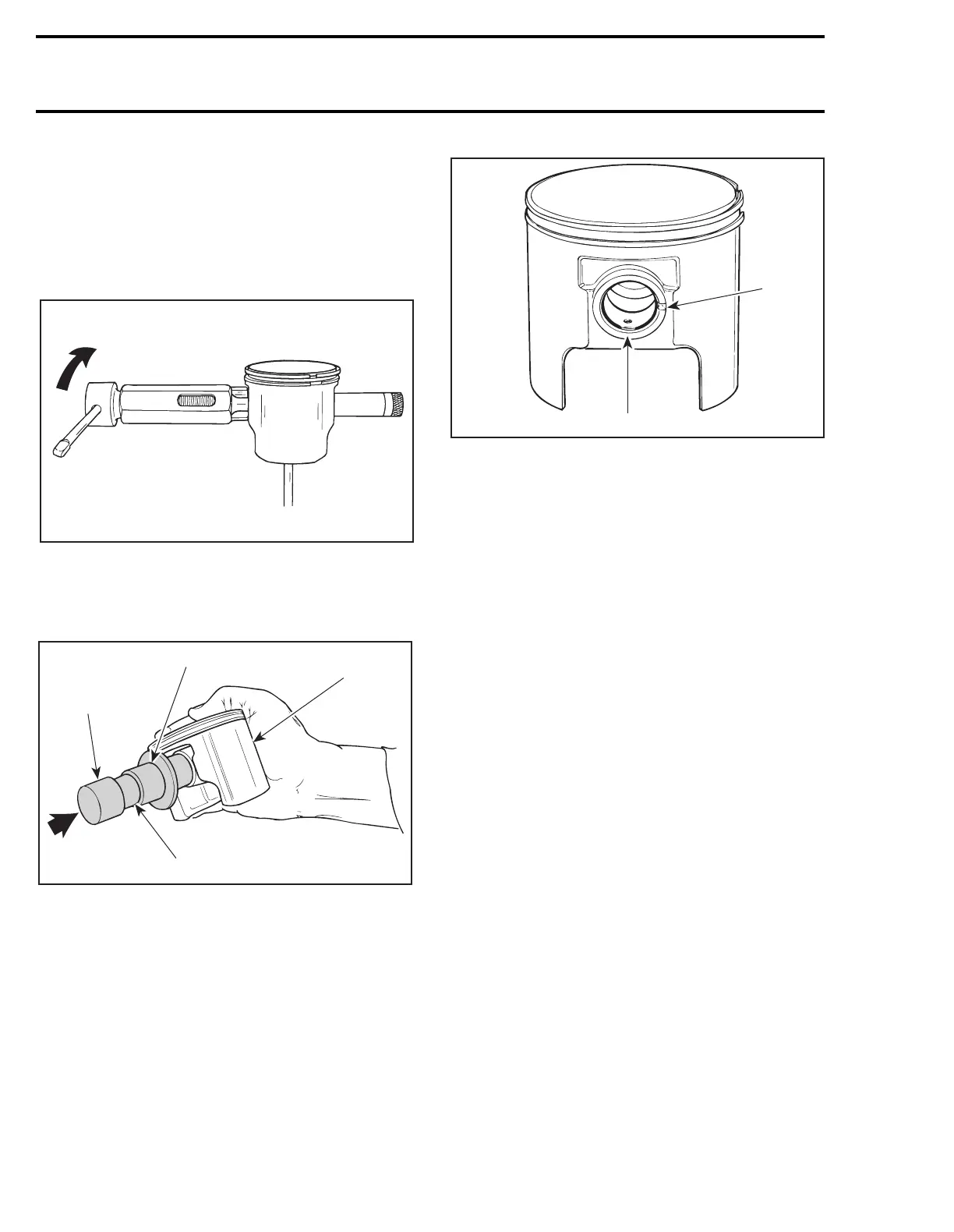

To minimize the effect of acceleration forces on

circlip, install each circlip so the circlip break is at

6 o’clock as illustrated. Use piston circlip installer

(P / N 529 0169 00).

1. Place circlip in

2. Restrain

3. Oil

1. Piston notch

2. Circlip break

CAUTION : Circlips must not move freely

in the groove after installation. If so, re-

place them.

Before inserting piston in the cylinder, lubricate

the cylinder with new injection oil or equivalent.

Position cylinder head on cylinder with fins in line

with crankshaft center line. Cross torque retaining

nuts to 26 N•m (19 lbf•ft) for 277 engine type.

A21C01A

A01B1QA

1

2

3

529 0169 00

1

2

A01C02A

Loading...

Loading...