Section 03 ENGINE

Sub-Section 03 (454, 494, 583 AND 670 ENGINE TYPES)

03-03-8

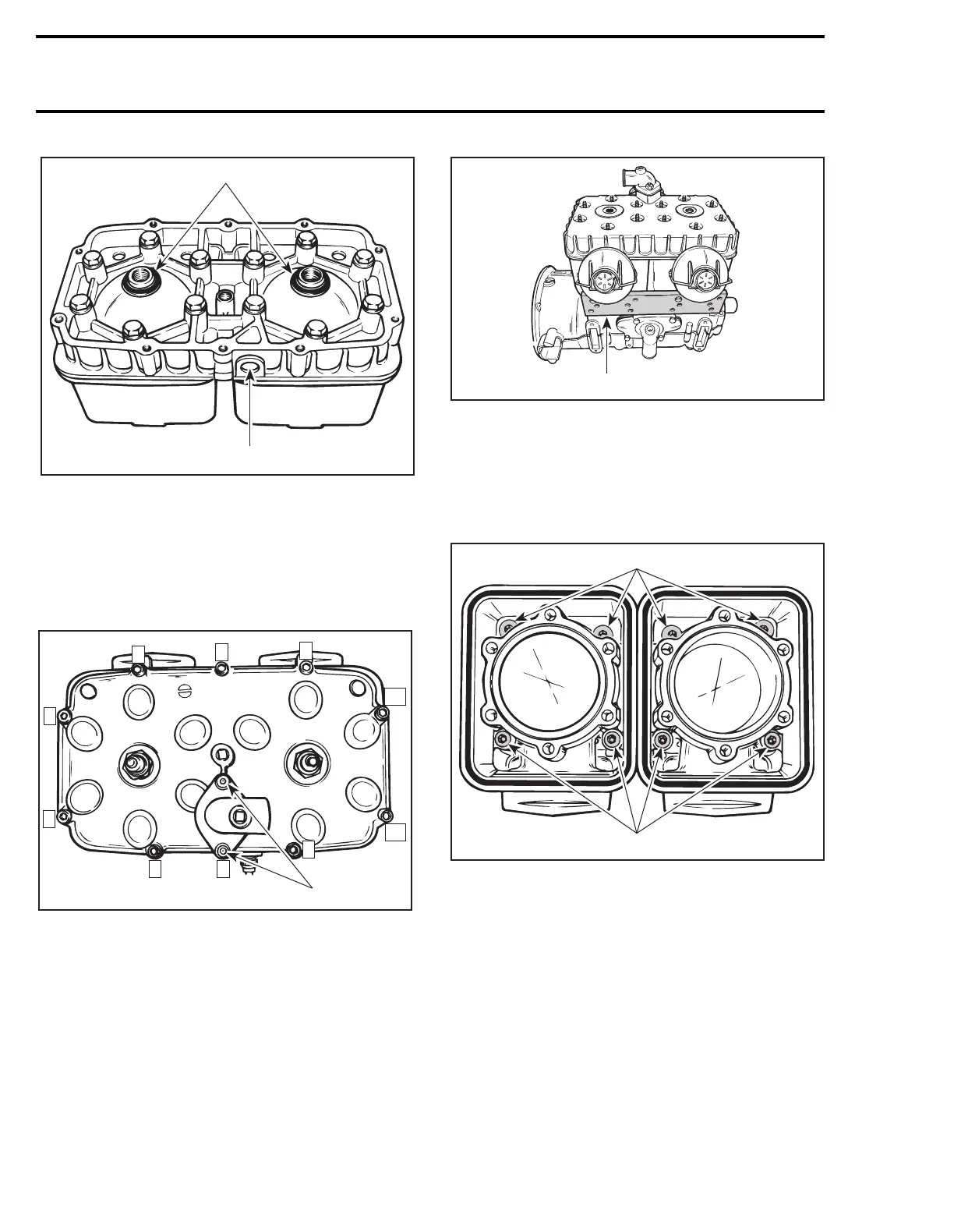

TYPICAL

1. O-rings

2. Temperature sensor hole

A. Torque to 29 N•m (21 lbf•ft)

1, Screw

Torque cylinder head cover screws to 10 N•m (90

lbf•

in

) as per following illustrated sequence.

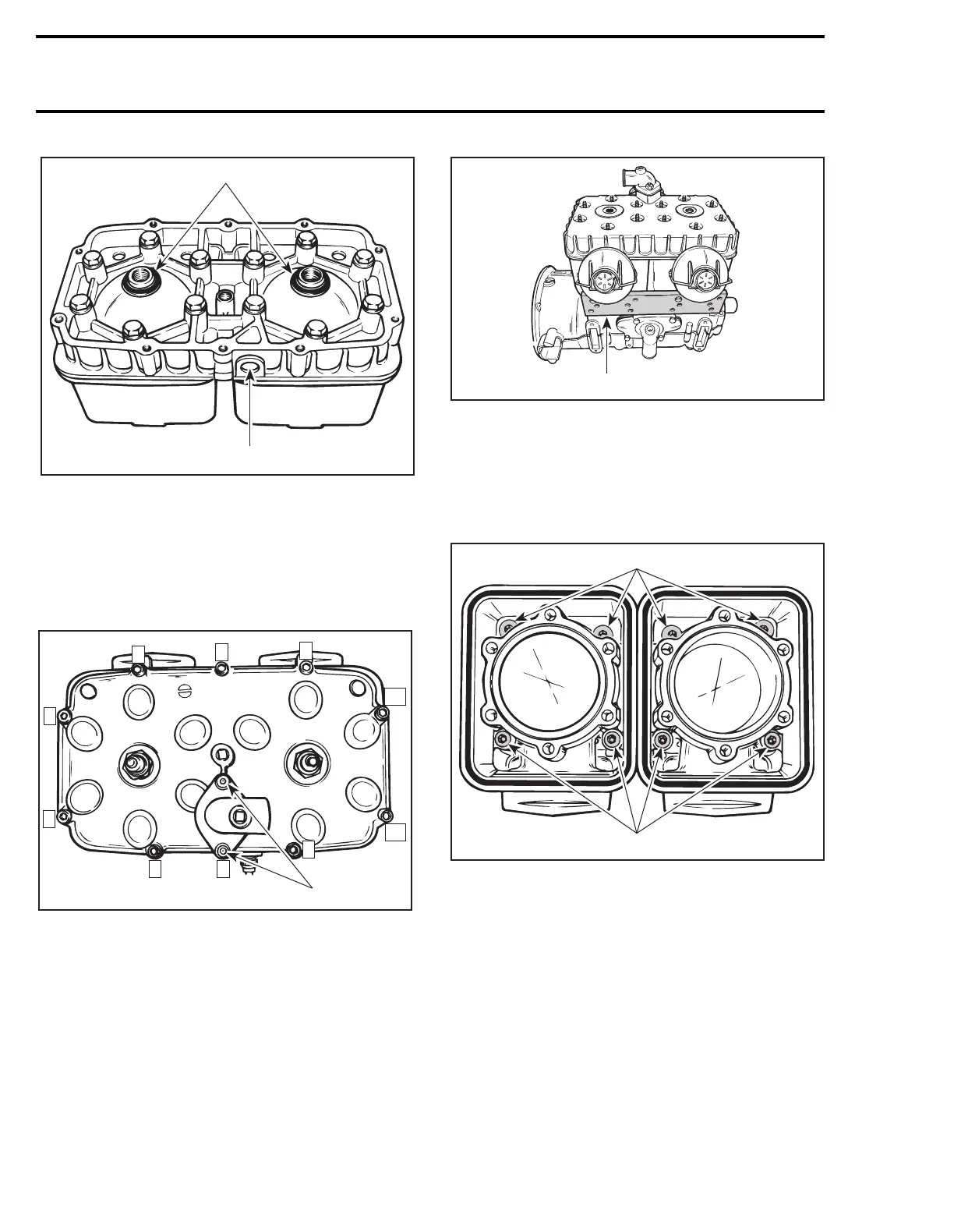

TYPICAL

1. Longer screws

454, 583 and 670 Only

When reassembling the cylinders to the crank-

case, it is important to have them properly aligned

so that the cylinder head holes will match up with

the studs. Cylinder head itself can be used to align

the cylinders. Prior to torquing crankcase/cylinder

nuts, install exhaust manifold to properly align ex-

haust flanges or use exhaust flange aligning tool

(P/N 420 8769 02).

Apply Loctite 242 (P/N 413 7030 00) on cylinder

screw threads.

Install and torque screws in a criss-cross se-

quence for each cylinder to 29 N•m (21 lbf•ft). For

454 and 670 engines longer screws go on exhaust

side.

TYPICAL

A. Torque screws to 29 N•m (21 lbf•ft)

17, Gasket

583 Only

Install gasket with its larger holes on exhaust side.

A25C0CA

1

2

A

A25C0DA

1

9

8

4

2

6

10

11

7

35

A24C0NA

420 8769 02

F01D13A

A

A

Loading...

Loading...