Section 03 ENGINE

Sub-Section 09 (ROTARY VALVE, COOLANT PUMP AND RESERVOIR)

03-09-7

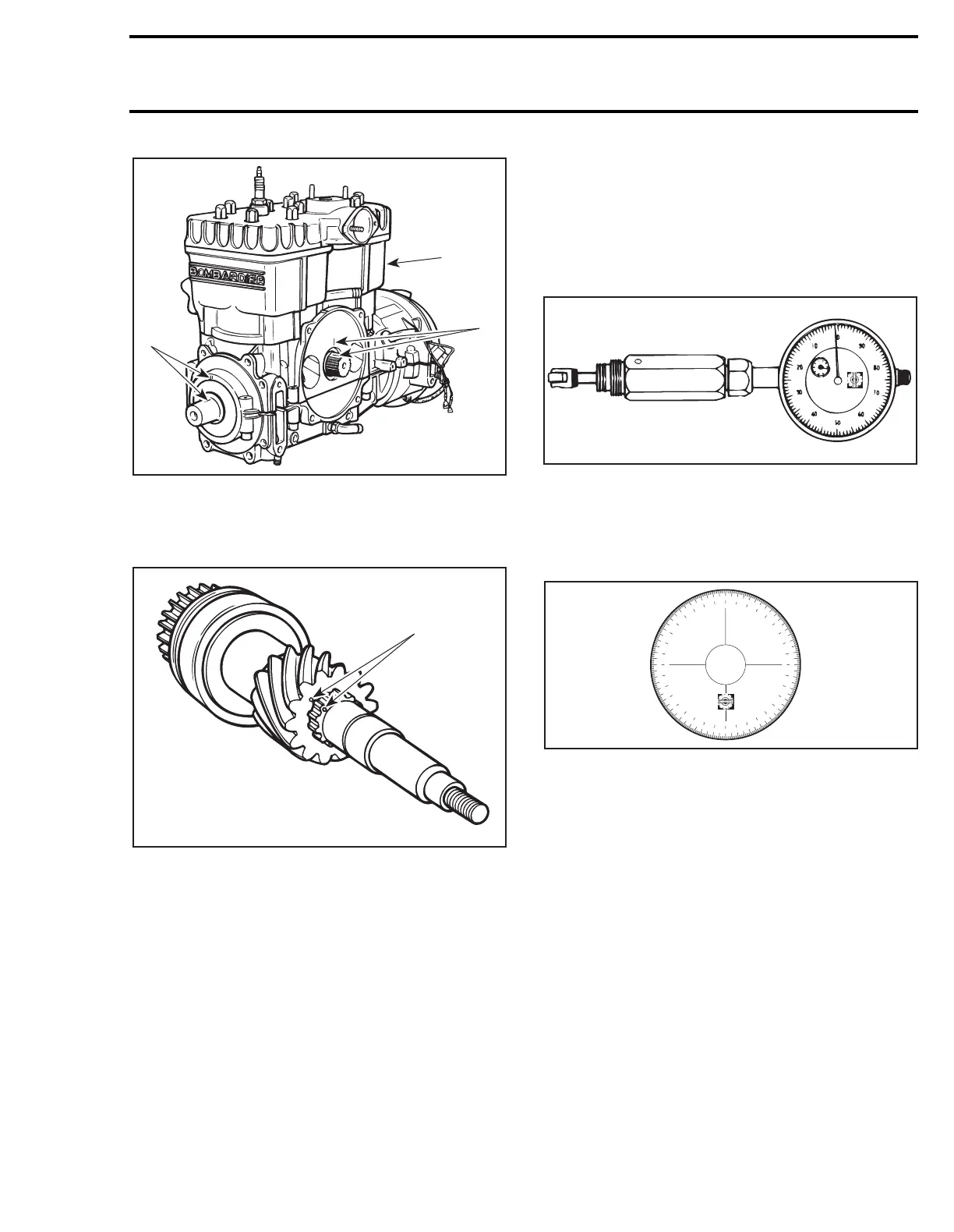

1. Mark here

2. MAG piston at TDC

After removing rotary valve shaft but before disas-

sembling, mark brass gear in relation to shaft.

1. Mark here

These marks will be useful to time rotary valve ex-

actly to the specifications.

NOTE:

Tolerance of rotary valve timing is ± 5

degrees.

When the same crankcase is reassembled, the

first timing method is to be followed. However

since replacement crankcases do not have timing

marks (ridge), the second method is required.

Take note that the second method is more accu-

rate and may be used any time.

Installation

To correctly install rotary valve, proceed as fol-

lows:

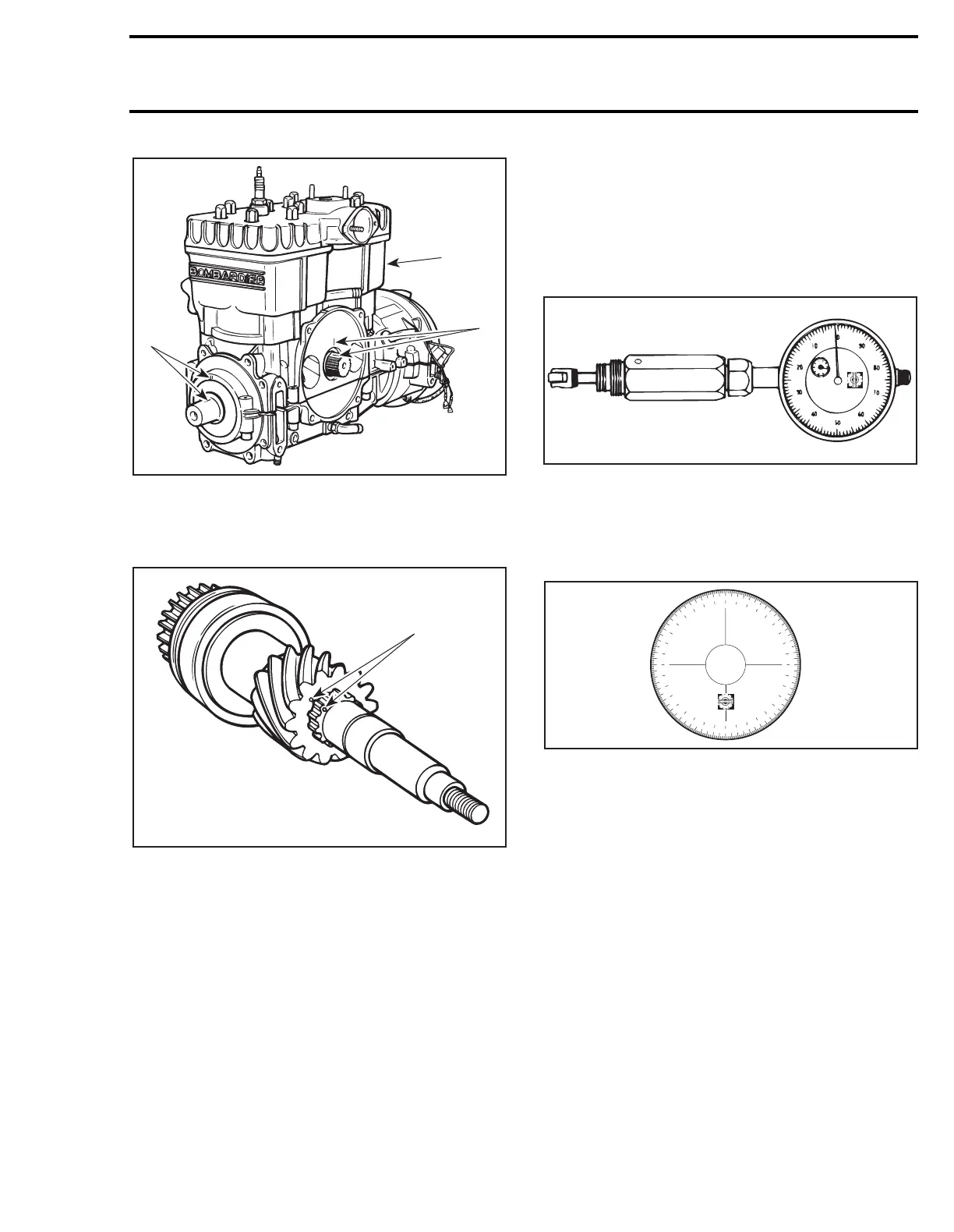

– Turning crankshaft, bring

MAGneto side

piston

to Top Dead Center.

Use a dial indicator (P/N 414 1047 00).

A degree wheel (P/N 414 3529 00) is required to

measure rotary valve opening and closing angles

in relation with

MAGneto side

piston. Degree

wheel will be installed on rotary valve shaft for

measurements.

Rotary valve must be set as specified in TECHNI-

CAL DATA 09.

For the following instructions, use these specifi-

cations as example:

OPENING: 132° BTDC

CLOSING: 52° BTDC

Proceed as follows:

– Turning crankshaft, bring

MAGneto side

piston

to Top Dead Center as done before with a

crankcase having a ridge.

– For opening mark, first align 360° line of degree

wheel with BOTTOM of

MAGneto side

inlet

port. Then, find 132° line on degree wheel and

mark crankcase at this point.

A16C16A

1

2

1

A16C17A

1

A00B2EA

414 1047 00

3

6

0

3

5

0

3

4

0

3

3

0

3

2

0

3

1

0

3

0

0

2

9

0

2

8

0

2

7

0

2

6

0

2

5

0

2

4

0

2

3

0

2

2

0

2

1

0

2

0

0

1

9

0

1

8

0

1

7

0

1

6

0

1

5

0

1

4

0

1

3

0

1

2

0

1

1

0

1

0

0

9

0

8

0

7

0

6

0

5

0

4

0

3

0

2

0

1

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

1

0

0

1

1

0

1

2

0

1

3

0

1

4

0

1

5

0

1

6

0

1

7

0

1

8

0

1

9

0

2

0

0

2

1

0

2

2

0

2

3

0

2

4

0

2

5

0

2

6

0

2

7

0

2

8

0

2

9

0

3

0

0

3

1

0

3

2

0

3

3

0

3

4

0

3

5

0

3

6

0

A00B33A

Loading...

Loading...