Section 03 ENGINE

Sub-Section 03 (377, 443 AND 503 ENGINE TYPES)

03-03-8

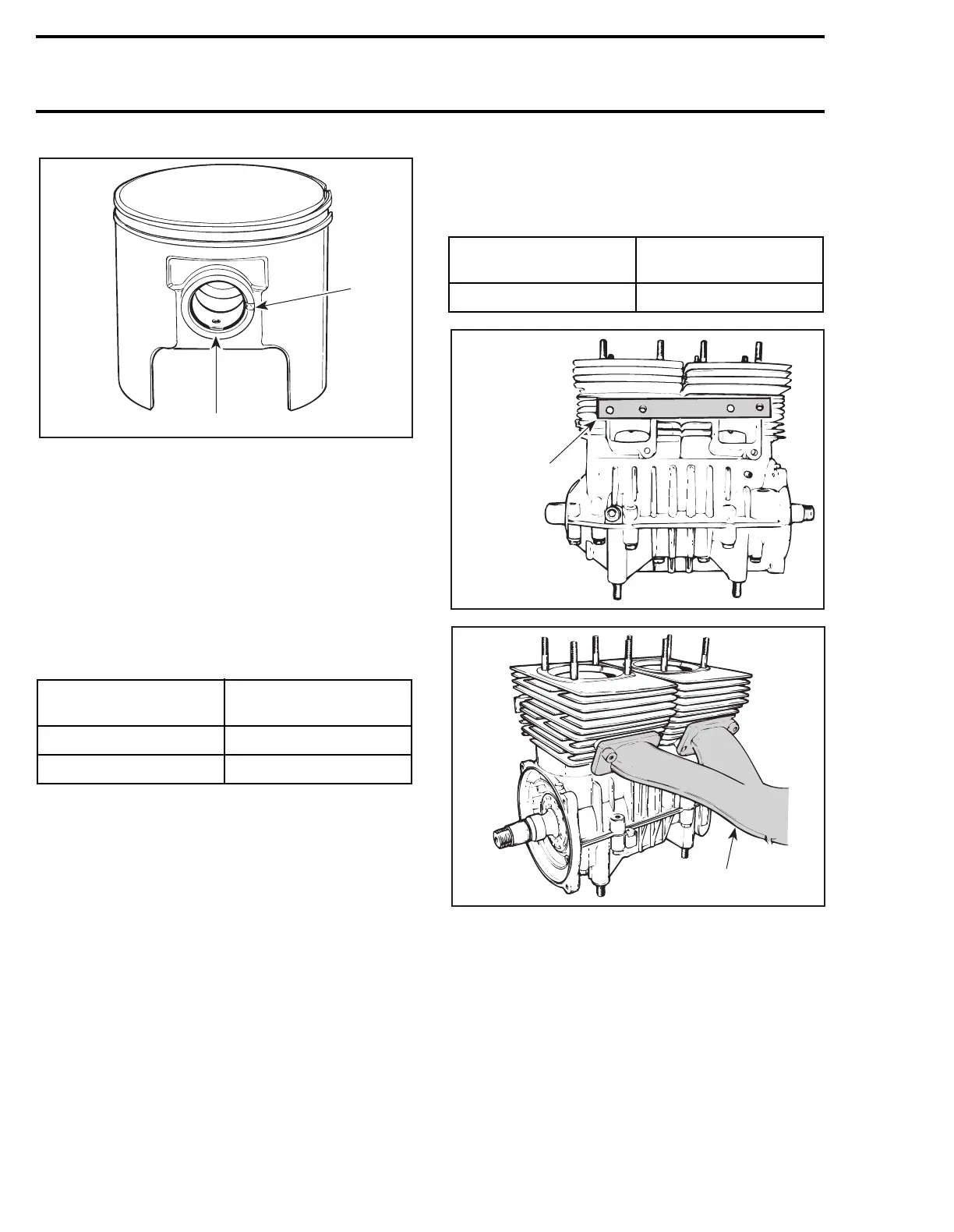

1. Piston notch

2. Circlip break at 6 o’clock

CAUTION : Circlips must not move freely

in the groove after installation. If so, re-

place them.

NOTE :

Be sure to restore the chamfer

around all cylinder sleeve port openings.

Before inserting piston in cylinder

no. 4

, lubricate

the cylinder with new injection oil or equivalent.

Install proper ring compressor on piston assem-

bly.

NOTE :

The ring compressor will not fit on

over size pistons.

Check flatness of intake sockets

no. 6

. Refer to

ENGINE DIMENSION MEASUREMENT 03-04

and look for

checking surface flatness

.

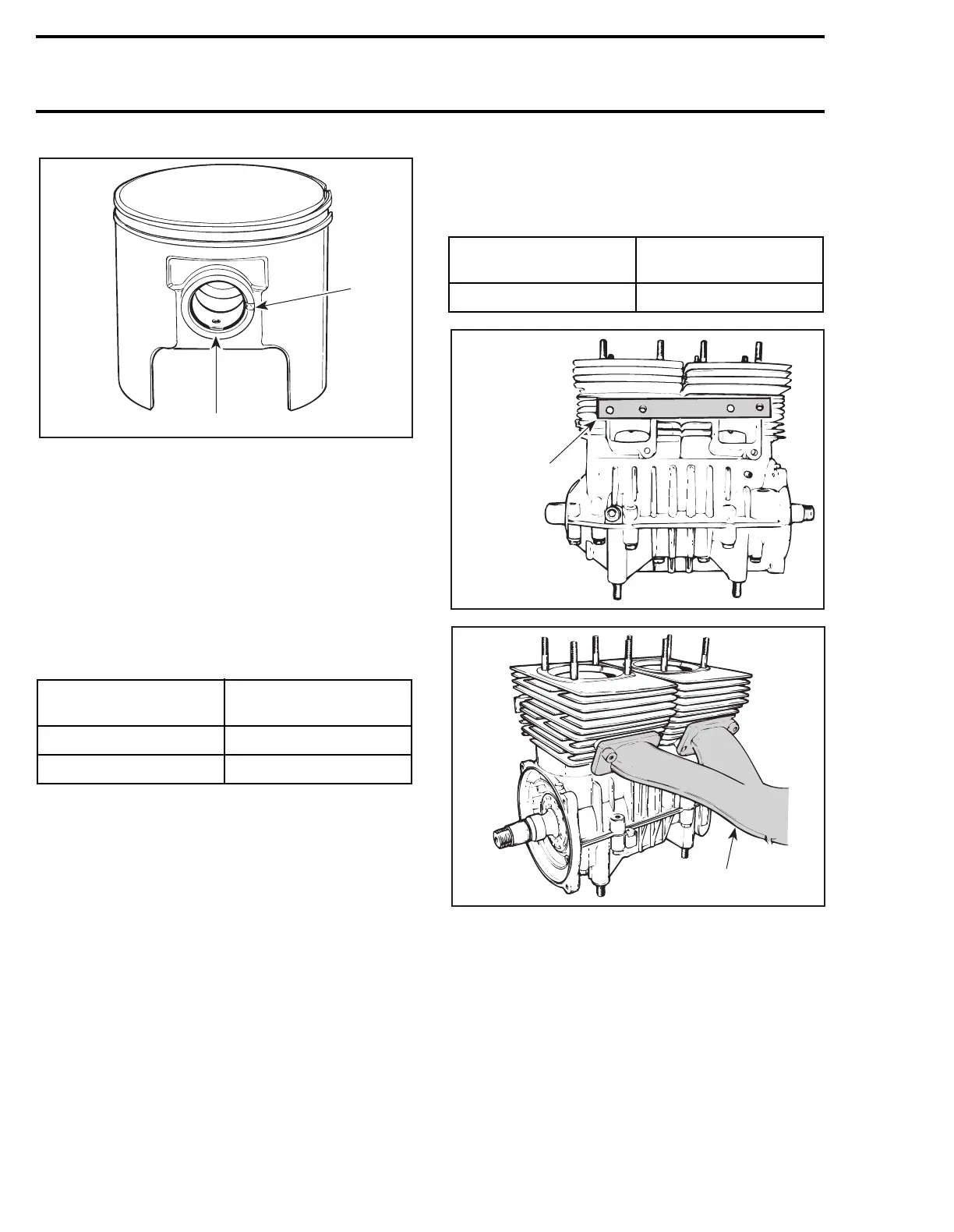

At cylinder

no. 4

and / or cylinder head

no. 3

in-

stallation, use aligning tool or exhaust manifold it-

self to ensure sealing of intake manifold and

exhaust before tightening cylinder head nuts.

1. Or use exhaust manifold to align cylinders

ENGINE TYPE

RING COMPRESSOR

P/N

377 420 8760 90

503 420 8769 70

1

2

A01C02A

ENGINE TYPE

ALIGNING TOOL

P/N

377, 443 and 503 420 8761 71

A17C01A

420 8761 71

A17C02A

1

Loading...

Loading...