Section 03 ENGINE

Sub-Section 08 (CARBURETOR AND FUEL PUMP)

03-08-6

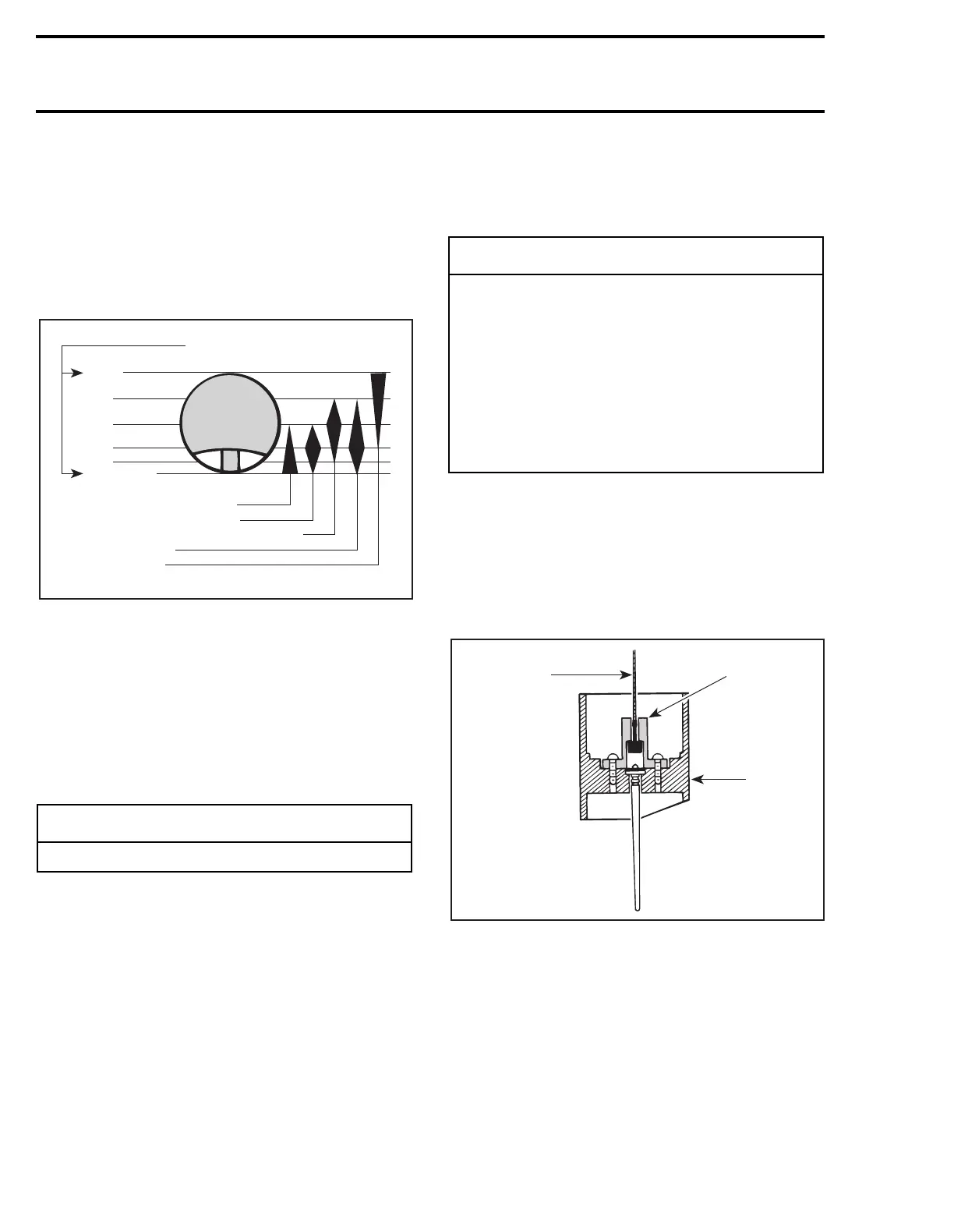

The following illustration shows the part of the

carburetor which begins and stops to function at

different throttle slide openings.

Note that the wider part of symbol corresponds to

the opening mostly affected. For instance, throt-

tle slide cut-away begins to function at closed po-

sition but it is most effective at 1/4 opening and

decreases up to 1/2 opening.

VIEW FROM AIR INTAKE OPENING

NOTE:

For fine tuning refer to TECHNICAL DATA

09-02 and to SPARK PLUG 05-03.

NOTE:

For high altitude regions, the

High Altitude

Technical Data Booklet

(P/N 484 0648 00 and 484

0545 00 for binder) gives information about cali-

bration according to altitude and temperature.

INSTALLATION

To install carburetor on engine, inverse removal

procedure.

However, pay attention to the following:

– Inspect throttle cable and housing prior to in-

stallation.

On applicable models, make sure to align tab of

carburetor and air intake silencer (if applicable)

with notch of adaptor(s). On applicable models, in-

stall adaptor with up mark facing up.

Install clamps in a way that their tightening bolts

are staggered — not aligned.

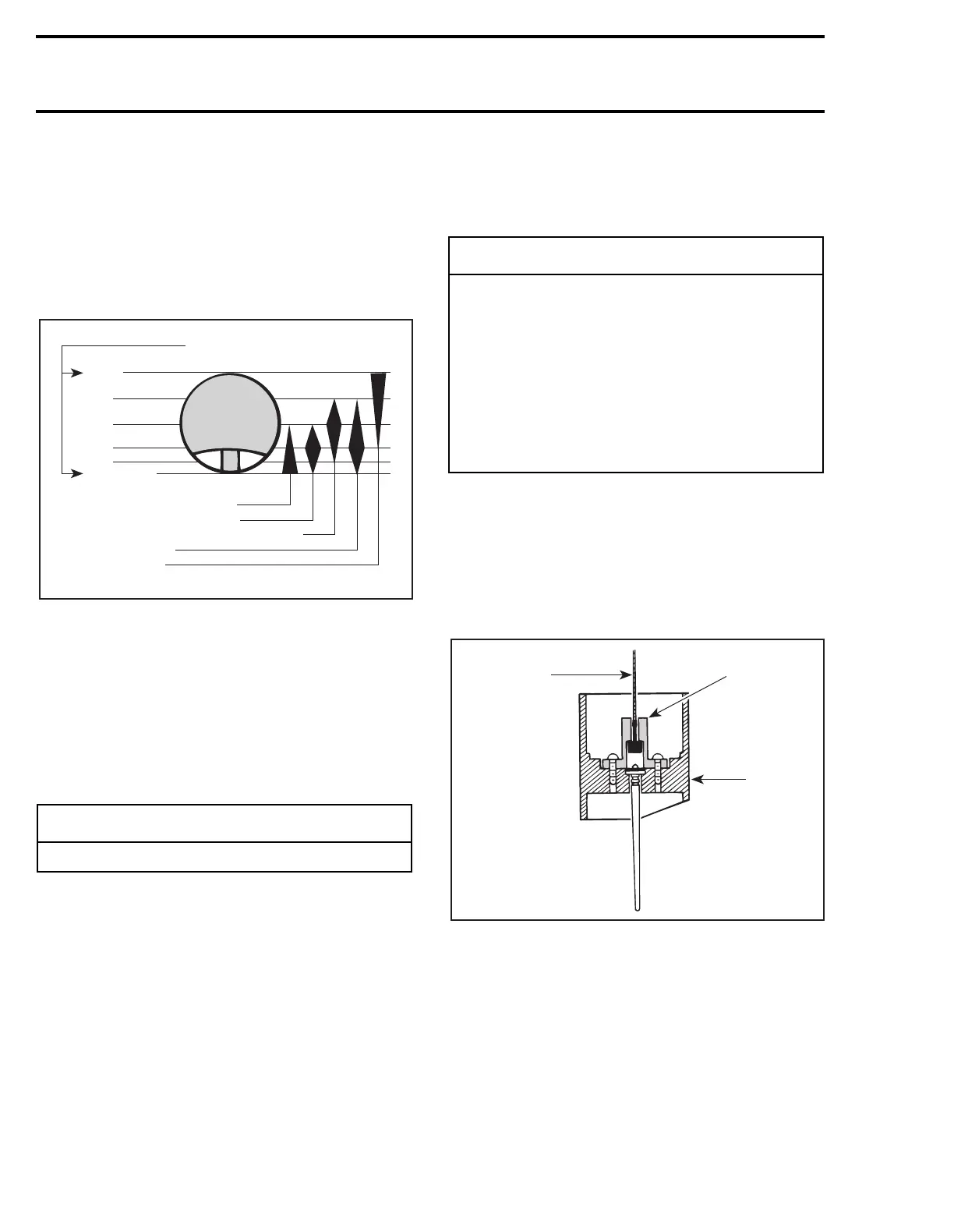

Hook throttle cable into the needle retainer plate.

NOTE:

Do not obstruct hole in throttle slide when

installing needle retaining plate. This is important

to allow air escaping through and thus allowing a

quick response.

CENTER POST TYPE

1. Throttle cable

2. Needle retaining plate

3. Throttle slide

-

CAUTION

Never allow throttle slide(s) to snap shut.

Throttle slide openings

Wide

open

3/4

1/2

1/4

1/8

Close

Pilot jet and air screw13,6,

Throttle slide cutaway5,

Needle taper and needle position3,

Needle jet14,

Main jet8,

A00C04A

-

CAUTION

The rubber flange must be checked for

cracks and/or damage. At assembly, the

flange must be perfectly matched with the

air intake manifold or severe engine damage

will occur. Beside do not interchange carbu-

retors, the jetting may be different on each

side. A red dot is printed on MAG carburetor

(blue on PTO side) and on the high tension

coil support. Match the carburetor and the

support dots.

A00C1TA

1

2

3

Loading...

Loading...