Section 03 ENGINE

Sub-Section 03 (377, 443 AND 503 ENGINE TYPES)

03-03-12

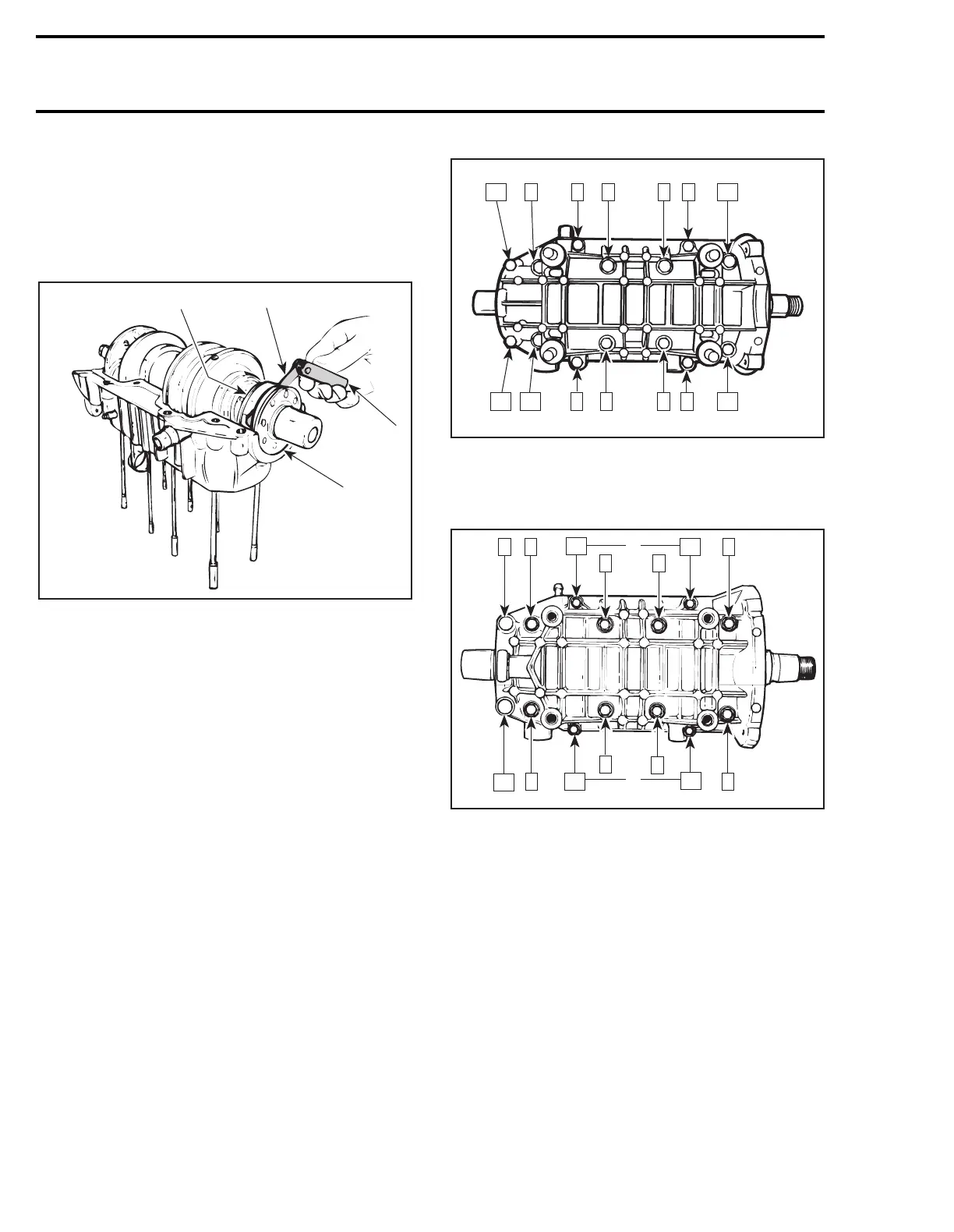

For bearing lubrication purpose, a gap of 1.0 mm

(.040 in) must be maintained between seals and

bearings.

When installing plain oil seals (seal without locat-

ing ring or without spacing legs), ensure to main-

tain 1.0 mm (.040 in) gap.

1. Bearing

2. Feeler gauge

3. Plain oil seal

A. 1 mm (.040 in)

Crankcase halves

nos. 1

and

9

are factory

matched and therefore, are not interchangeable

as single halves.

Prior to joining of crankcase halves, spray some

new injection oil (or equivalent) on all moving

parts of the crankshaft. Spray Primer N (P / N 413

7081 00) on one of mating surfaces. Let it dry for

10 to 20 minutes.

Apply paste gasket (P / N 413 7027 00)

no. 5

on

the other mating surface.

NOTE :

Primer N allows Loctite 515 to fully

cure on aluminum surfaces. It increases fill-

ing capacity and reduce curing time.

Position the crankcase halves together and tight-

en bolts by hand then install and tighten armature

plate on magneto side to correctly align the crank-

case halves.

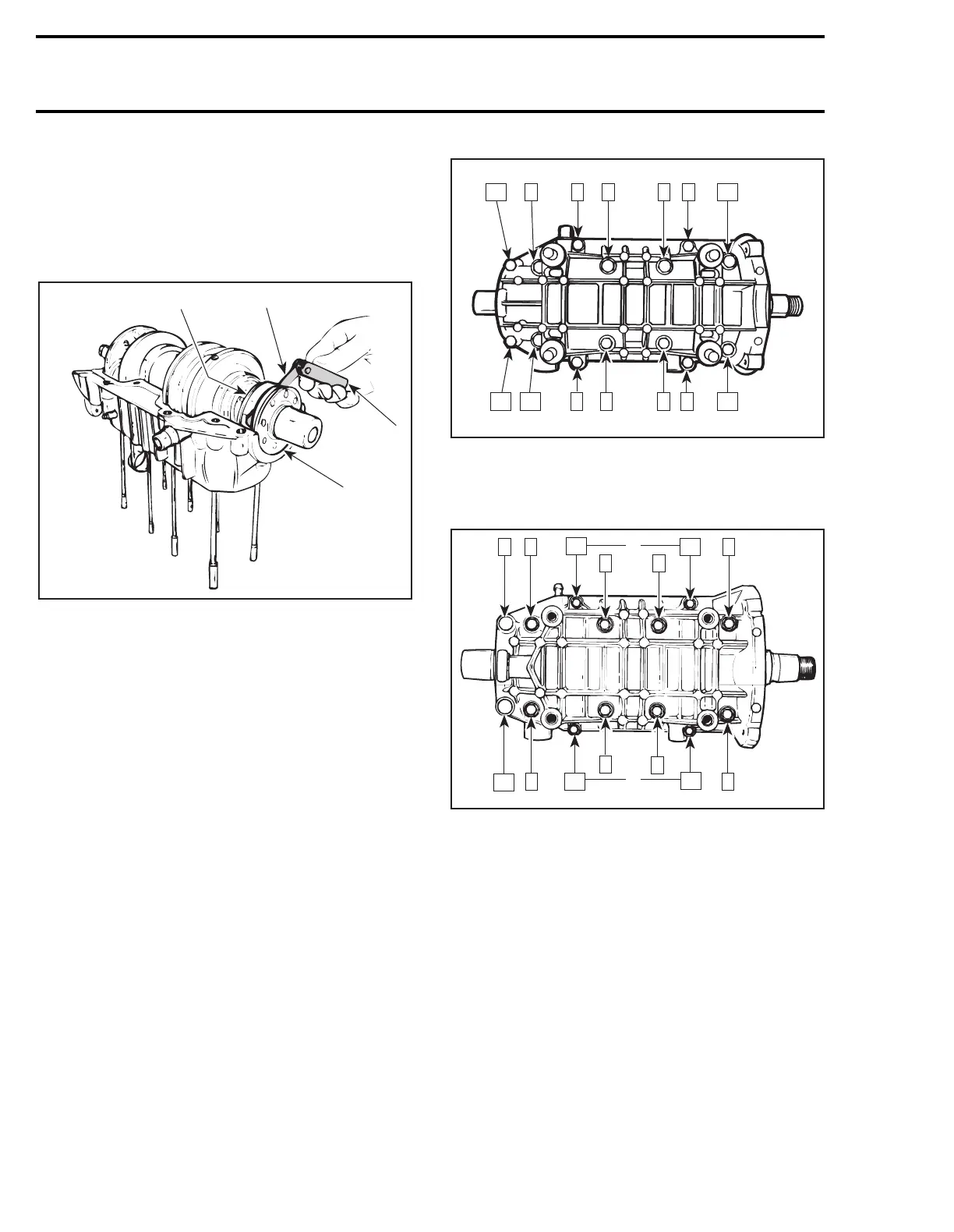

503 Engine Type

Torque screws

nos. 6, 7, 8

and

11

to 22 N•m (16

lbf•ft) following illustrated sequence.

377 and 443 Engines

Torque screws to proper torque in the following

sequence.

A. 10 N

•

m (89 lbf

•

in)

All the other screws are torqued to 21 N•m (15 lbf•ft)

All Engines

To install magneto, refer to CDI MAGNETO 03-05.

A17C07A

1 A

2

3

115317913

14 10 6 4 2 8 12

A17C08A

10

8 14

4

2

12

6

5

11

31

13

79

A

A

A09C05A

Loading...

Loading...