Working in water and on boggy ground

Be very careful when working on boggy ground.

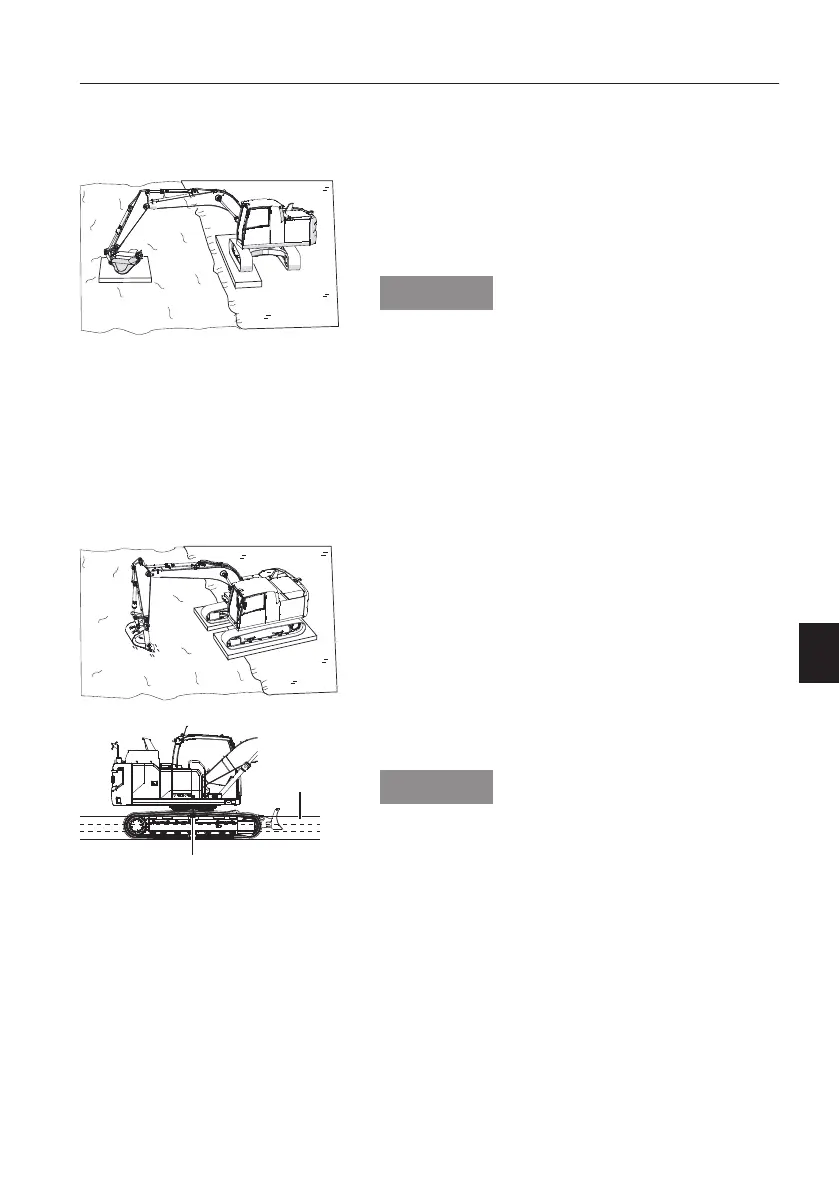

In case that one track gets bogged

If one track gets bogged down, raise this track using

the bucket and put a plank under the track.

NOTICE

When the machine is lifted with the aid of the boom

or the dipper arm, the bottom of the bucket should

rest on the ground not the bucket teeth.

Set the angle between boom and dipper arm at 90

° ~ 110 °.

After working in water or escaping from boggy

ground, replenish the grease to the attachment pins

or the areas affected by the water. Check the idler,

rollers and track drive case oil, if contaminated,

change the oil.

In case both tracks get bogged

In case that both tracks get bogged down, put

planks under each track. Thrust the bucket into the

ground, pull with the dipper arm as when digging,

and move the travel lever forward to escape.

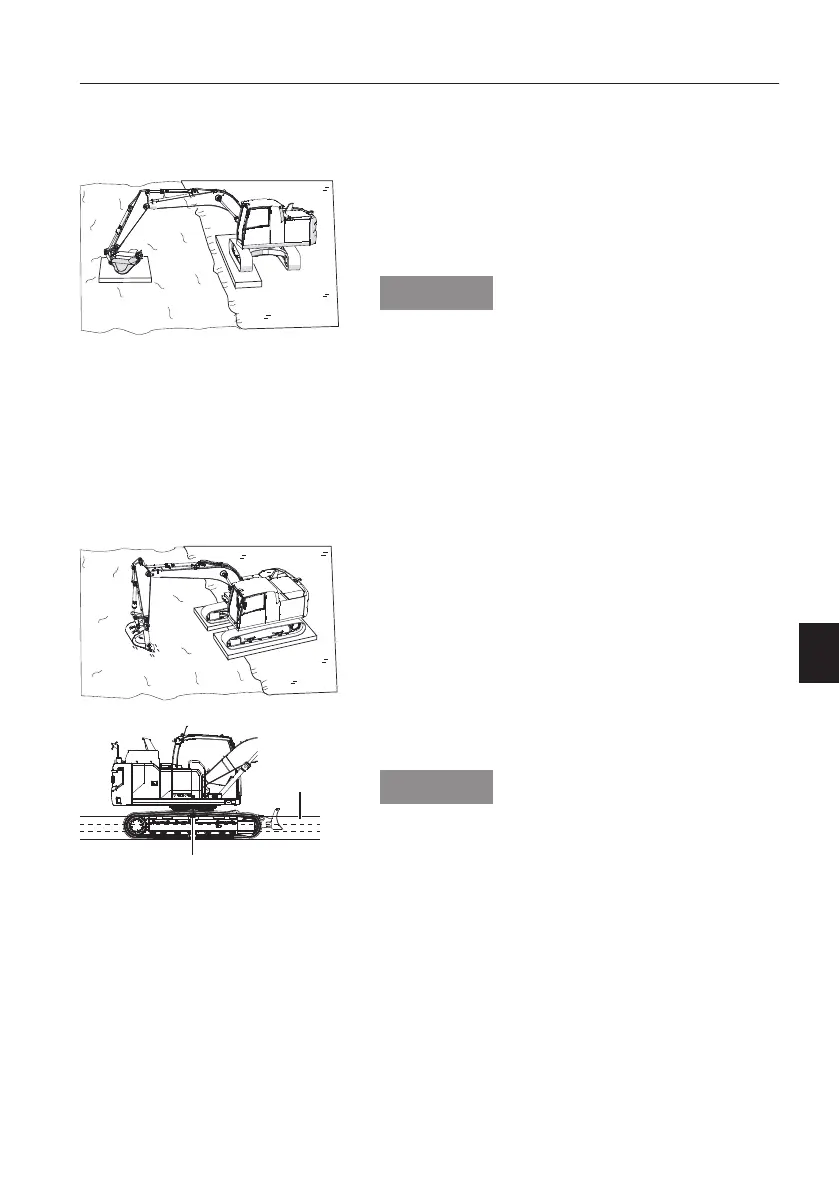

Permissible depth of water

NOTICE

Pay attention to the permissible water depth in

order to avoid damage to the machine.

Permissible working depth in water is the center of

top rollers.

Do not fully submerge the top rollers.

Upon leaving the water, make sure all the grease is

replenished in the areas affected by the water, for

example bucket pin and so on, remove the old

grease completely regardless of the maintenance

period. Also check the oil in the travel drive for

contamination, and if necessary, replace it.

1 Top roller

2 Water level

Operating techniques

Working within dangerous areas

219

Loading...

Loading...