Maintenance2303−1/A1

Winterthur Gas & Diesel Ltd.

6/ 12

14) Put the two parts of the distance piece 94231B (12 mm height) on the

gaskets 12, 14 (see Fig. 7).

15) Put the four parts of the gaskets 12, 13 on the distance piece 94231B. Make sure

that there is an equal distance between the four parts.

16) Make sure that all horizontal spring dowel pins 18 and the vertical spring dowel

pin 17 are installed (see Fig. 8).

Note: On top of the scraper rings 11 there is one hole for a vertical spring dowel

pin.

17) Put the scraper ring 11 on the gaskets 12, 13. Make sure that there is an equal

distance between the four parts.

18) Make sure that the vertical spring dowel pin 17 (Fig. 4) is installed.

19) Use the assembly tool 94233 to attach the tension spring 19 to the scraper

ring 11.

Note: There is no hole for a vertical spring dowel pin on the top of the scraper

ring 10.

1) Put the scraper ring 10 on the top of

the scraper ring 11. Make sure that

there is an equal distance between the

four parts.

2) Make sure that the vertical spring

dowel pin 17 between the scraper ring

10 and the scraper ring 11 is correctly

installed (see Fig. 6).

3) Use the assembly tool 94233 to attach

the tension spring 19 to the scraper

ring 10.

4) Remove the distance piece 94231B.

5) Remove the clamp ring 94231A.

6) Put the template 94231E over the

assembled rings (see Fig. 9). Make

sure that all parts are in the correct

position. If necessary, correct the

position.

7) Apply bearing oil to the piston rod and

the assembled rings.

8) Push the two parts of the housing (2)

over the assembled rings (see Fig. 9).

Make sure that the dowel pins (4,

Fig. 6) are installed.

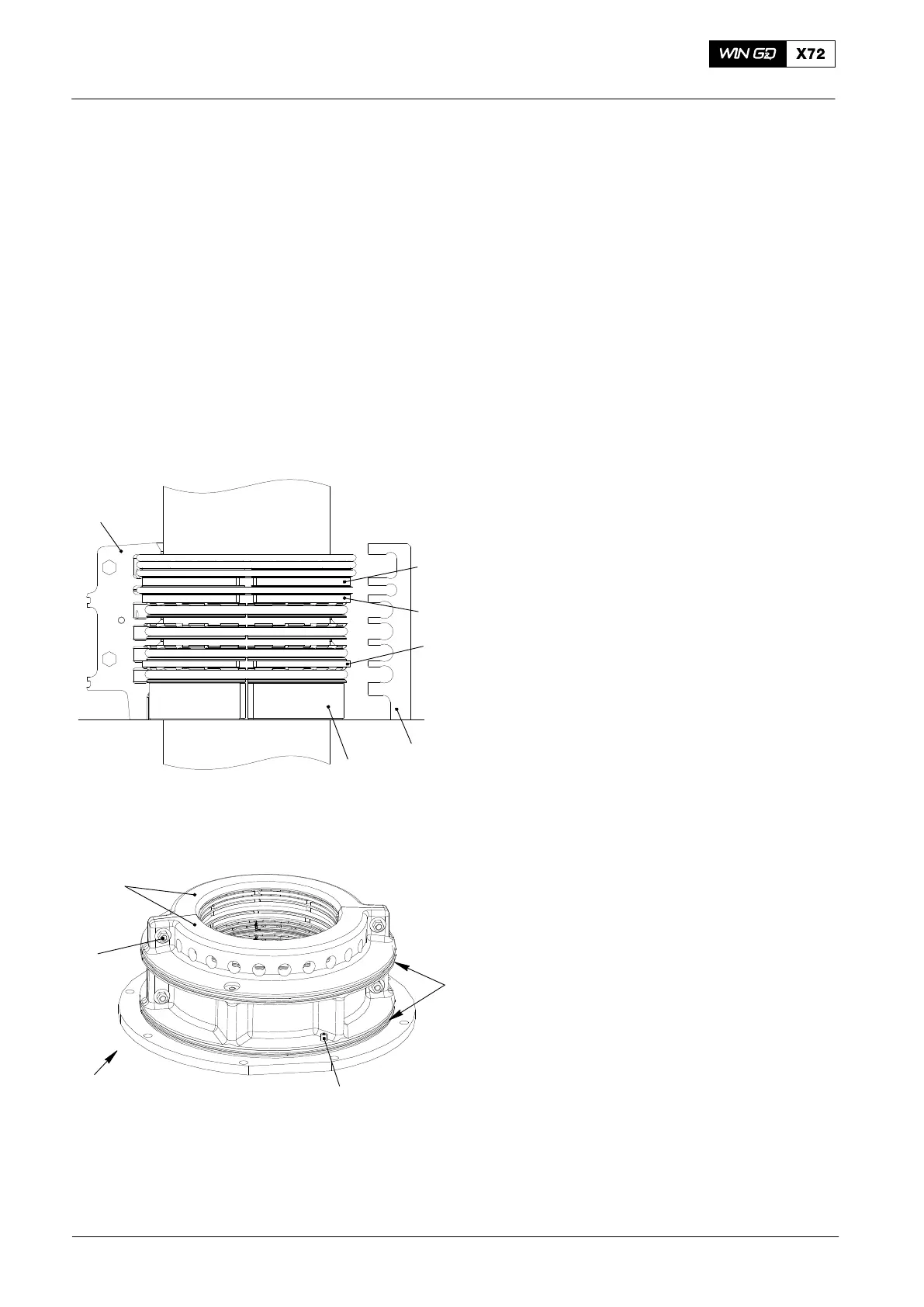

9) Torque the screws (3, Fig. 10) to the

value given in 0352-2 Torque Values for

Standard Screws, paragraph 1.

10) Attach oiled O-rings (5) to the housing

(2).

11) Put dowel pin (4) in place, see Fig. 10.

Fig. 9

94231E

94231A

94231D

94231C

94231B

2

Fig. 10

3

4

1

WCH02376

2

5

Loading...

Loading...