Maintenance

3303−2/A1

Winterthur Gas & Diesel Ltd.

3/ 7

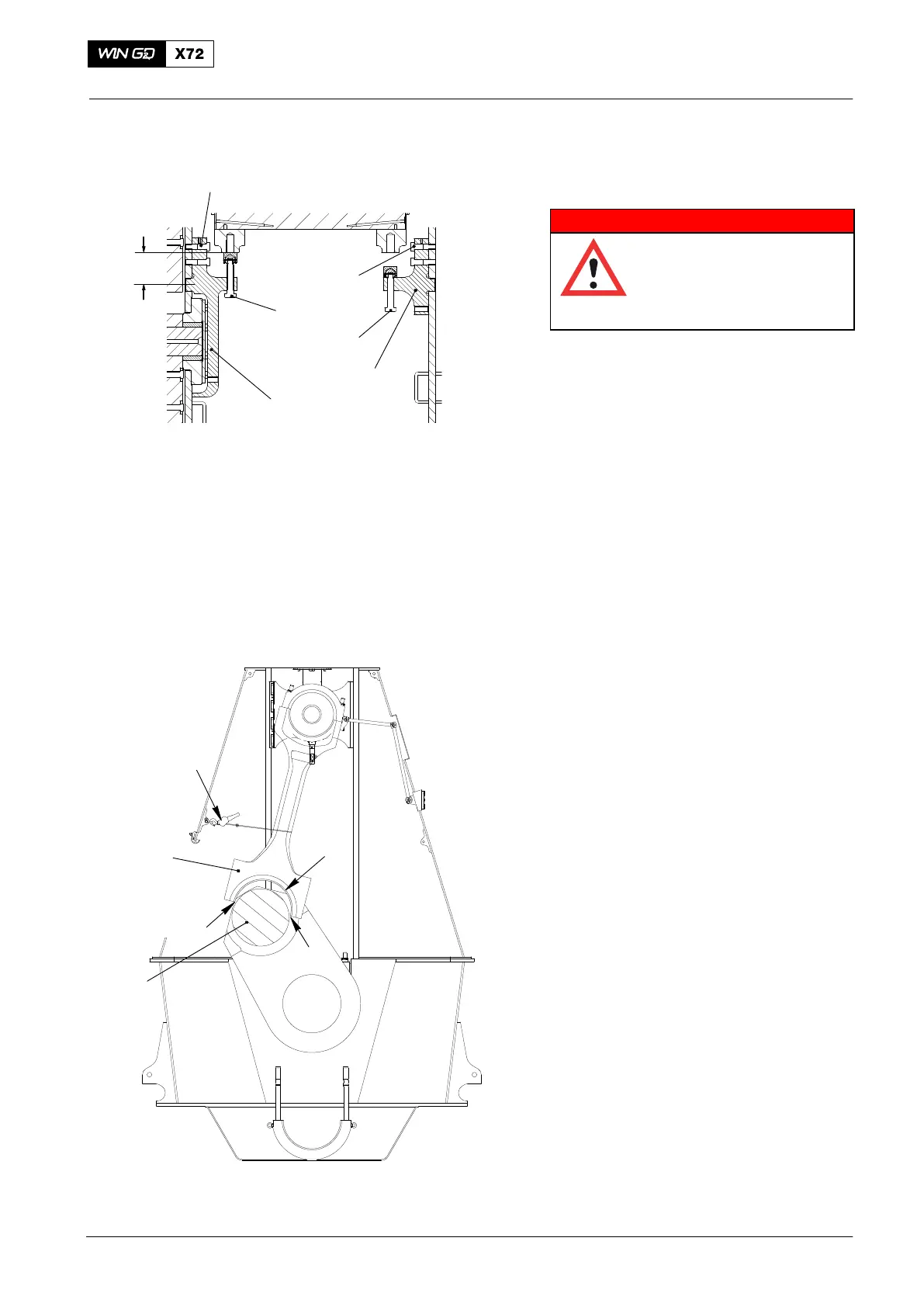

4. Top Bearing Shell −

Inspection

WARNING

Injury Hazard: Before you

operate the turning gear,

make sure that no

personnel are near the

flywheel, or in the engine.

1) Unlock the turning gear.

2) Use the turning gear to turn the crank

to fuel side until the crosshead is

appoximately 300 mm above the plug

bore center (see Fig. 4).

Note: Fig. 4 shows an engine with

electric Balancer (iELBA). Use two

supports 94322 for engines

without balancer.

3) Put a small quantity of clean oil on the

four bolts(1, 4).

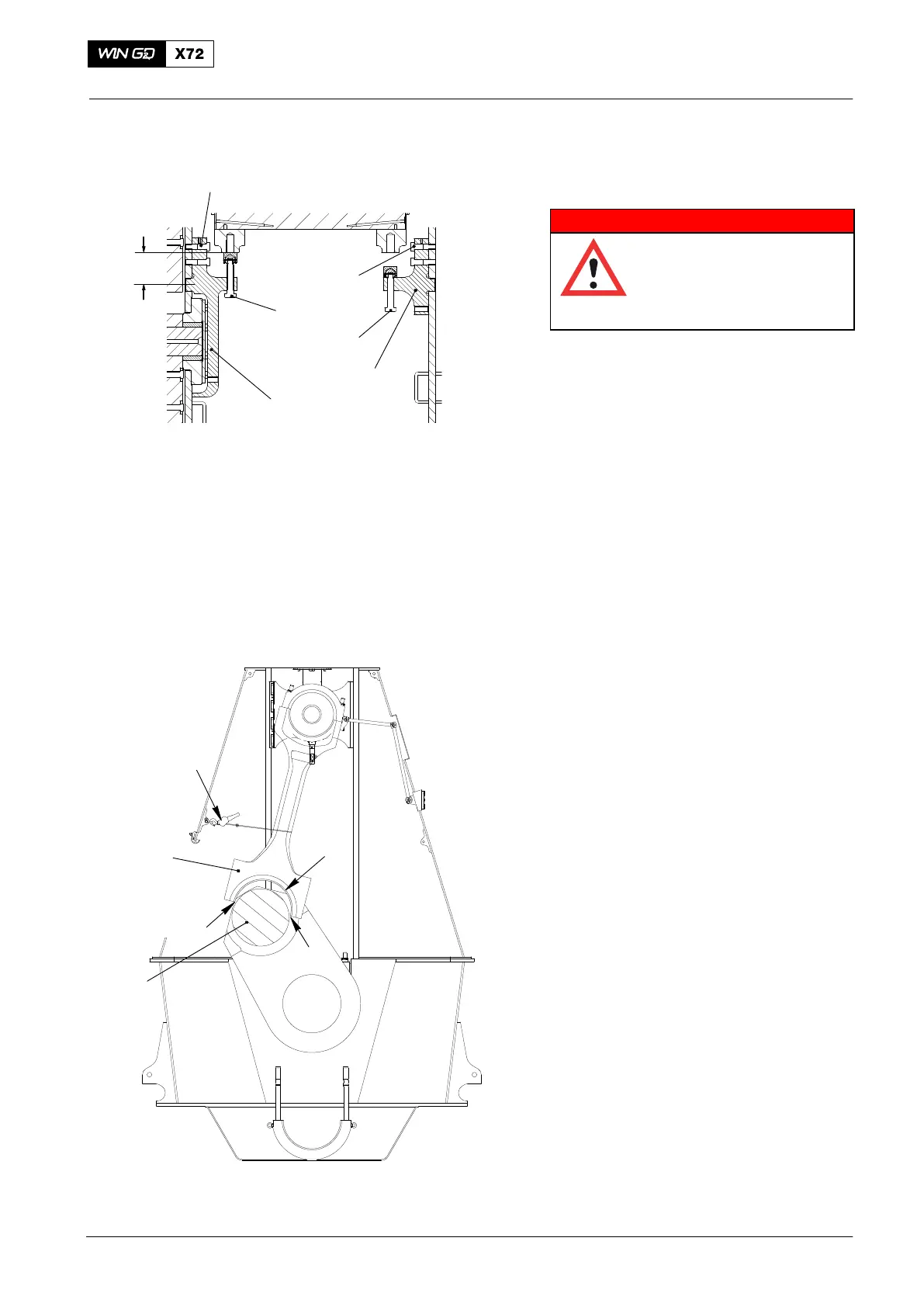

4) Attach the two supports (2x 94322 or

for iELBA: 1x 94322A and 1x 94322)

with the four bolts (1, 4).

5) Torque the four bolts (1, 4) to 300 Nm.

6) Use the turning gear to lower

crosshead for 140 mm (160 mm above

plug bore center).

7) Tighten the special screws (2, 3) on

each support.

8) Put the chain of the manual ratchet

(H3, Fig. 5) around the connecting

rod (1).

9) Use the turning gear to turn the crank

to fuel side. Keep the tension on the

manual ratchet H3 to prevent .

10) Make sure there is no load on the

corners (X) of the bearing shell (10).

11) Turn the crank to 100° after TDC.

12) Examine the bearing shell (10).

2016−02

Bottom End Bearing − Removal, Inspection and Installation

Fig. 4

WCH02423

10

H3

1

X

X

2

Fig. 5

WCH03208

94322

2

94322A

3

160 mm

1

4

Loading...

Loading...