3.11 Problems that Can Frequently Occur during Setup and Possible Solutions

226 YASKAWA SIEPC71061723A YASKAWA AC Drive CR700 Technical Manual

3.11 Problems that Can Frequently Occur during Setup and

Possible Solutions

If the drive or motor operate incorrectly, but the keypad does not show a fault or error code, refer to the items this

section.

• Motor hunting and oscillation

• Unsatisfactory motor torque

• Unsatisfactory speed precision

• Unsatisfactory motor torque and speed response

• Motor noise

Note:

If you synchronize two drives or if you use one drive that switches between more than one motor, the method to make adjustments is

different. For these applications, contact Yaskawa about drive settings and drive adjustments.

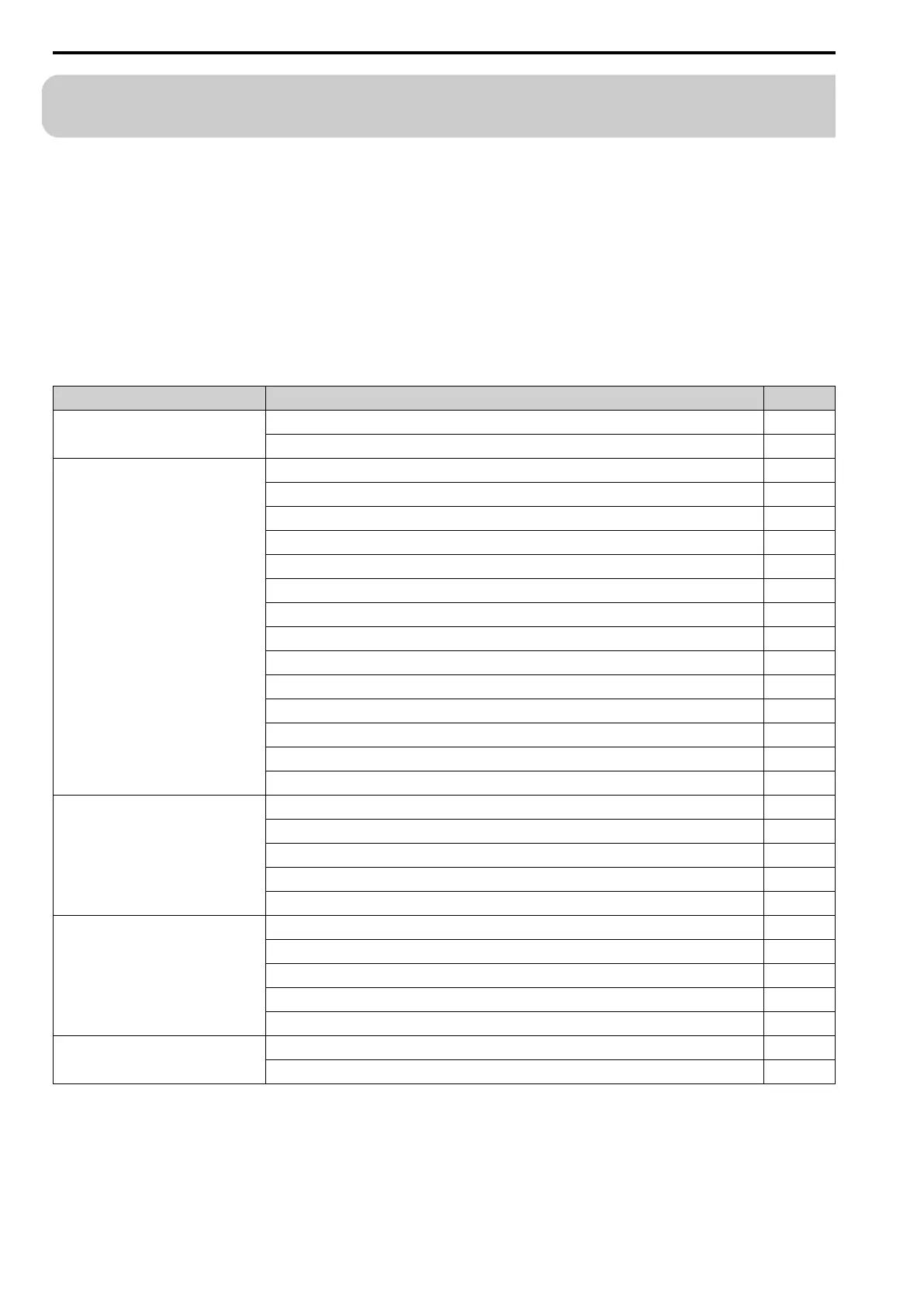

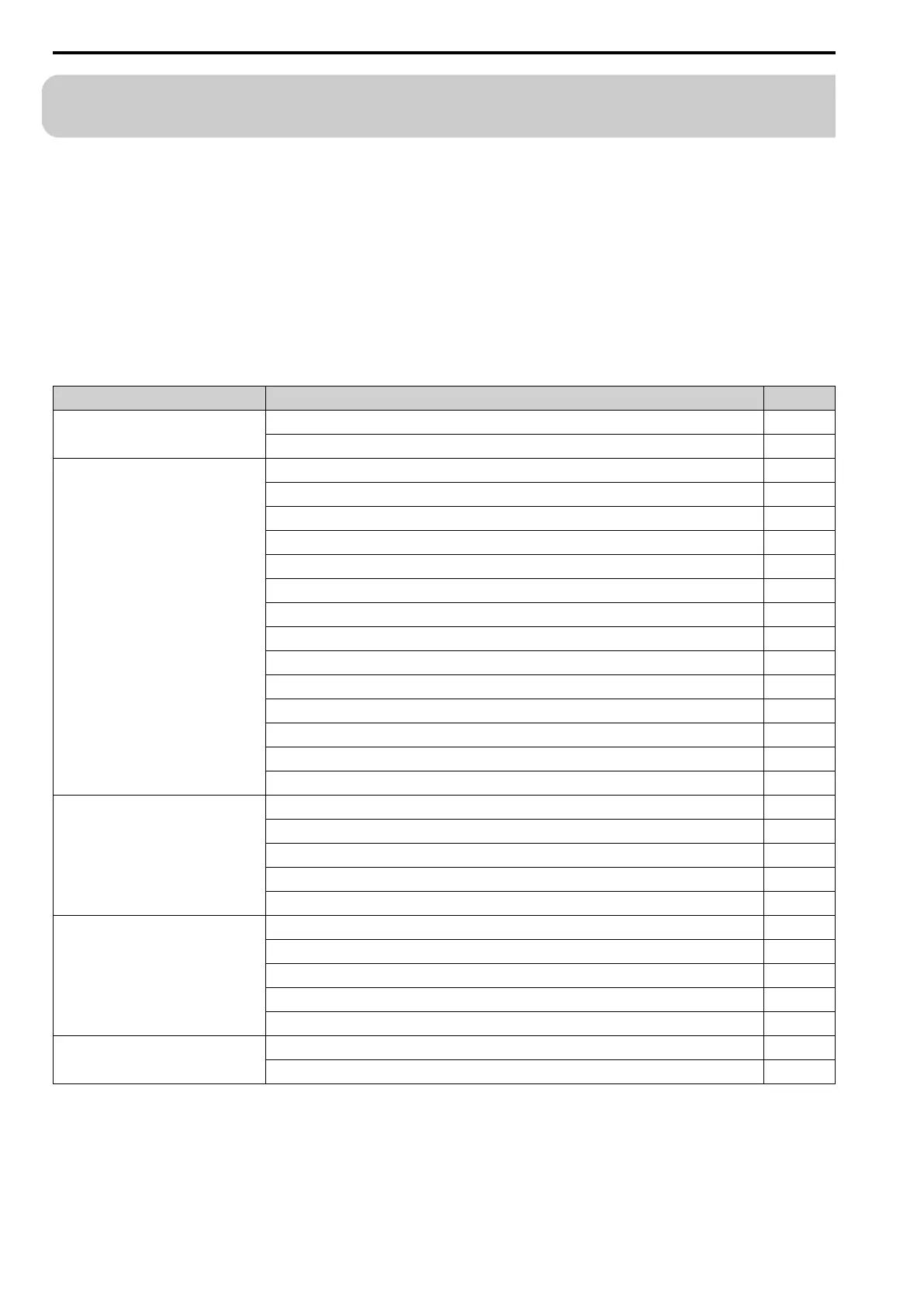

Table 3.27 Typical Problems

Classification Problem Ref.

Keypad Operation Cannot Change Parameter Settings

227

The Correct Auto-Tuning Mode Is Not Available

227

Motor Does Not Operate Correctly Crane Sequence Does Not Operate

227

Motor Does Not Rotate After Entering Run Command

227

The Starting Torque Is Not Sufficient

228

Motor Does Not Restart after Power Loss

228

Motor Rotates in the Opposite Direction from the Run Command

229

Motor Rotates in One Direction Only

229

Motor Stops When Operating at the Brake Release Frequency Speed

229

Response Is Slow at Start

229

Motor Stalls during Acceleration or Accel/Decel Time Is Too Long

229

Output Frequency Is Not As High As Frequency Reference

230

Drive Frequency Reference Differs from the Controller Frequency Reference Command

231

Large Inconsistency in Stopping Position Due to the Load Rate

231

Deceleration Takes Longer Than Expected When Dynamic Braking Is Enabled

231

The Motor Rotates after the Drive Output Is Shut Off

231

Suspension Drops or Load Slips Suspension Drops (Falls)

231

Load Slips at Start

232

Load Slips at Stop

232

Slipping Occurs During Extremely Fast Inching

232

Load Falls When Brake Is Applied

232

Too Much Output Current Excessive Current Occurs at Start

232

Excessive Output Current at Constant Speed

233

Too Much Output Current, Oscillation

233

Despite Measures to Increase Flux, Brake Operation Is Slow and Peak Current at Start Take Too Long

233

Excessive Current Flow When Starting to Hoist Immediately After Stopping Lowering

233

Brake Grinding Brake Slips at Start

234

Brake Grinding Occurs at Stop

234

Loading...

Loading...