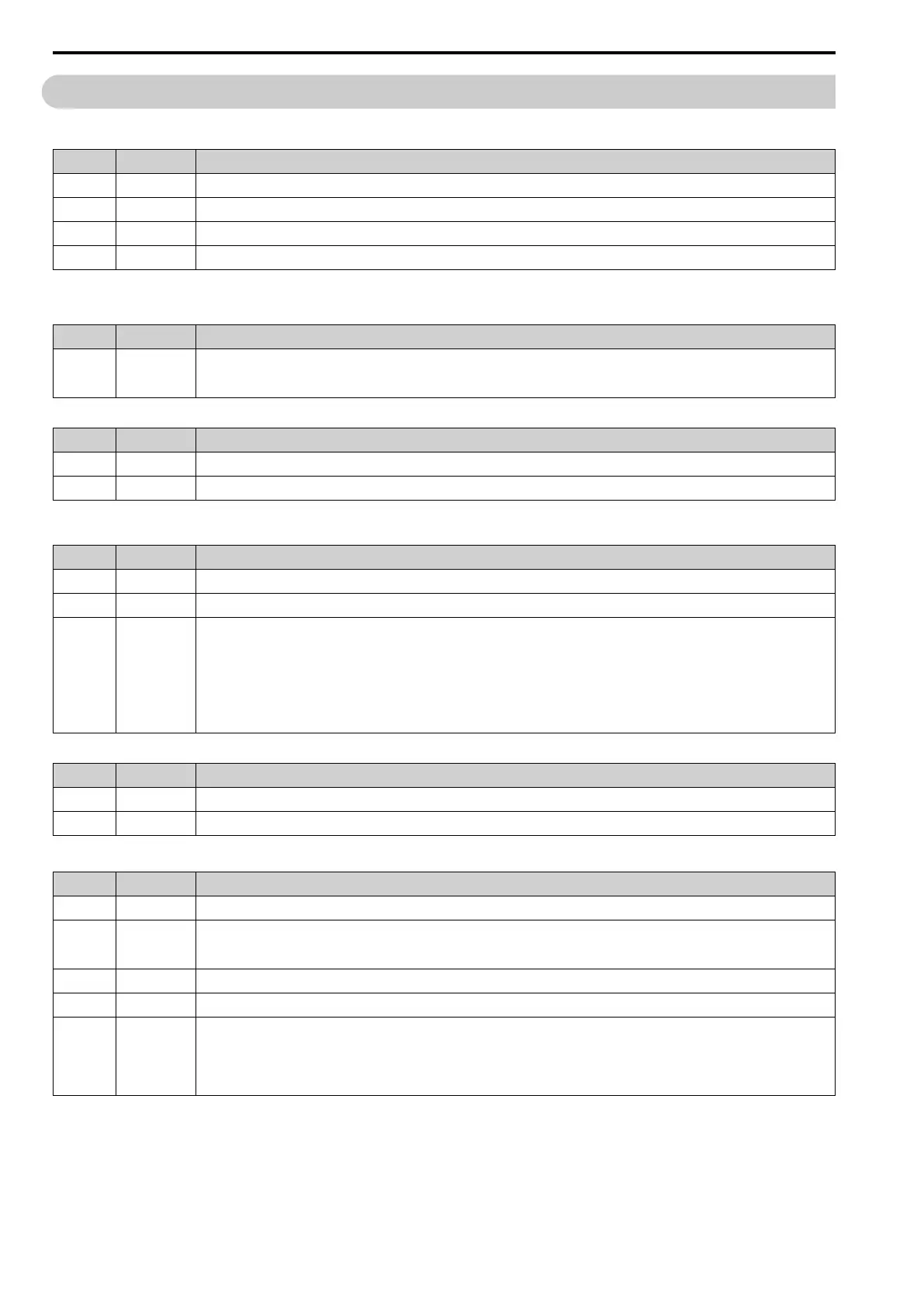

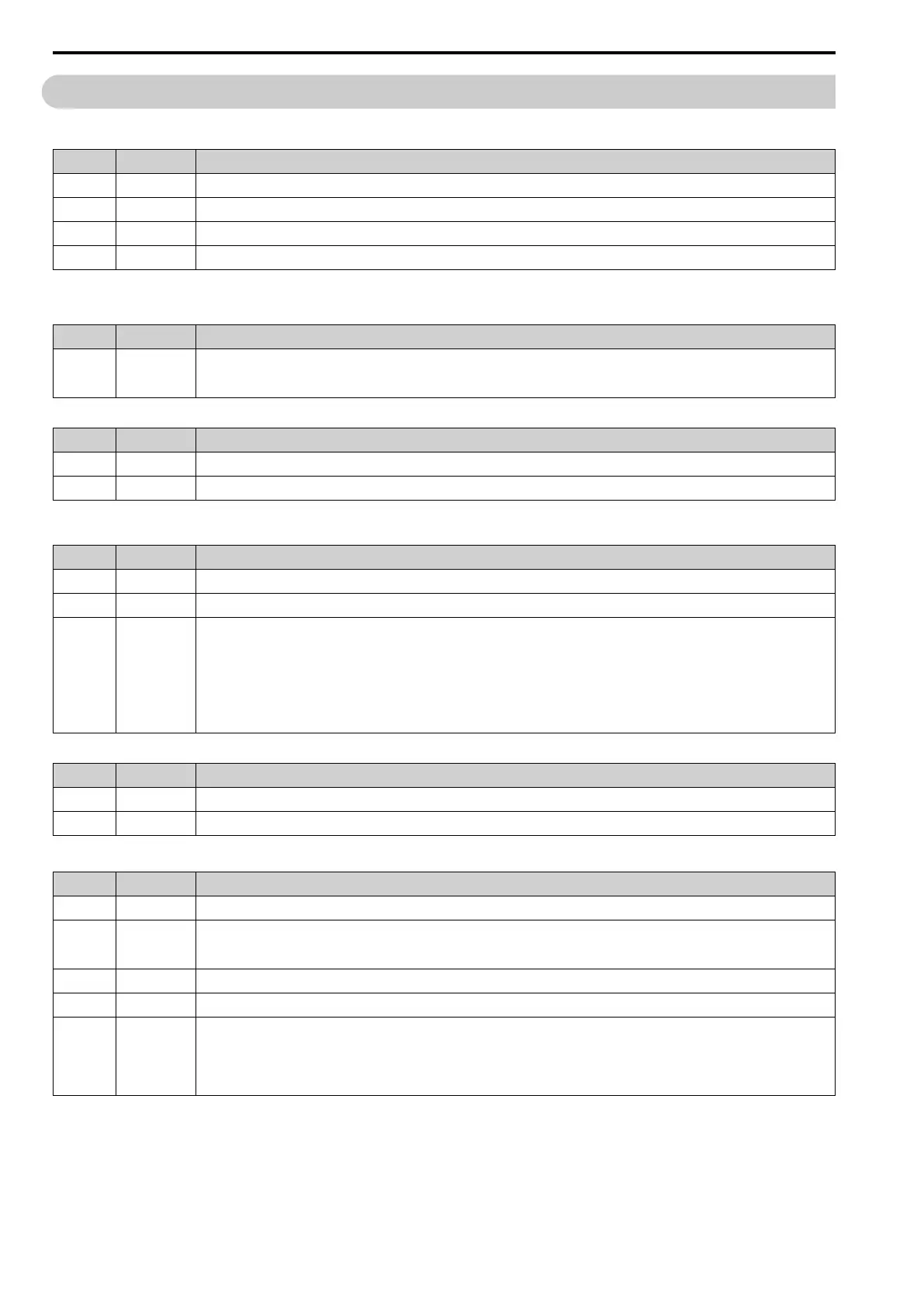

3.13 Test Run Checklist

242 YASKAWA SIEPC71061723A YASKAWA AC Drive CR700 Technical Manual

3.13 Test Run Checklist

Review this checklist and check each item before you do a test run.

Checked No. Description

1 Thoroughly read this manual before you do a test run.

2 Check the ”Wiring Checklist”.

3 Energize the drive.

4 Set the voltage for the power supply in E1-01 [Input AC Supply Voltage].

Check the applicable items as specified by your control method.

Table 3.33 V/f Control [A1-02 = 0] and Closed Loop V/f Control [A1-02 = 1]

Checked No. Description

5

Select the best V/f pattern for your application and motor characteristics.

Example: For a motor with a rated frequency of 60 Hz, set E1-03 = 1 [V/f Pattern Selection = Const Trq, 60Hz base, 60Hz max] as a standard V/

f pattern.

Table 3.34 Closed Loop V/f Control [A1-02 = 1]

Checked No. Description

6

Set F1-01 [Encoder 1 Pulse Count (PPR)] correctly and make sure that encoder pulse counting direction is correct.

7

Set C5-01 [ASR Proportional Gain 1] and C5-02 [ASR Integral Time 1].

Table 3.35 Open Loop Vector Control [A1-02 = 2], Closed Loop Vector Control [A1-02 = 3], Advanced Open Loop Vector

Control [A1-02 = 4]

Checked No. Description

8

Do Rotational Auto-Tuning.

9

Decouple motor shafts and machines when you do Rotational Auto-Tuning

10

Refer to the information on the motor nameplate and set this data correctly:

• Motor rated power (kW) to T1-02

• Motor rated voltage (V) to T1-03

• Motor rated current (A) to T1-04

• Motor base frequency (Hz) to T1-05

• Number of motor poles: T1-06

• Motor base speed (min

-1

) to T1-07

Table 3.36 Closed Loop Vector Control [A1-02 = 3]

Checked No. Description

11

Set F1-01 [Encoder 1 Pulse Count (PPR)] and F1-05 [Encoder 1 Rotation Selection].

12

Set C5-01 [ASR Proportional Gain 1] and C5-02 [ASR Integral Time 1].

Check items 5 to 12, then check these items.

Checked No. Description

13

The keypad will show “Rdy” after starting to operate the motor.

14

Make sure that you set b1-01 [Frequency Reference Selection 1] and b1-02 [Run Command Selection 1] correctly as specified by the input

source of the Run command and frequency reference

Example: To input the frequency reference and Run command from the keypad, set b1-01 = 0 [Keypad] or b1-02 = 0 [Keypad].

15

If the motor rotates in the opposite direction during test run, switch two of the motor cables (U/T1, V/T2, W/T3).

16

Set E2-01 [Motor Rated Current (FLA)] and L1-01 [Motor Overload (oL1) Protection] correctly for motor thermal protection.

17

When you use terminal A1 for the frequency reference:

• Voltage input

– Set H3-01 = 0, 1 [Terminal A1 Signal Level Select = 0 to 10V (Lower Limit at 0), -10 to +10V (Bipolar Reference)].

– Set H3-02 = 0 [Terminal A1 Function Selection = Frequency Reference].

Loading...

Loading...