3.11 Problems that Can Frequently Occur during Setup and Possible Solutions

232 YASKAWA SIEPC71061723A YASKAWA AC Drive CR700 Technical Manual

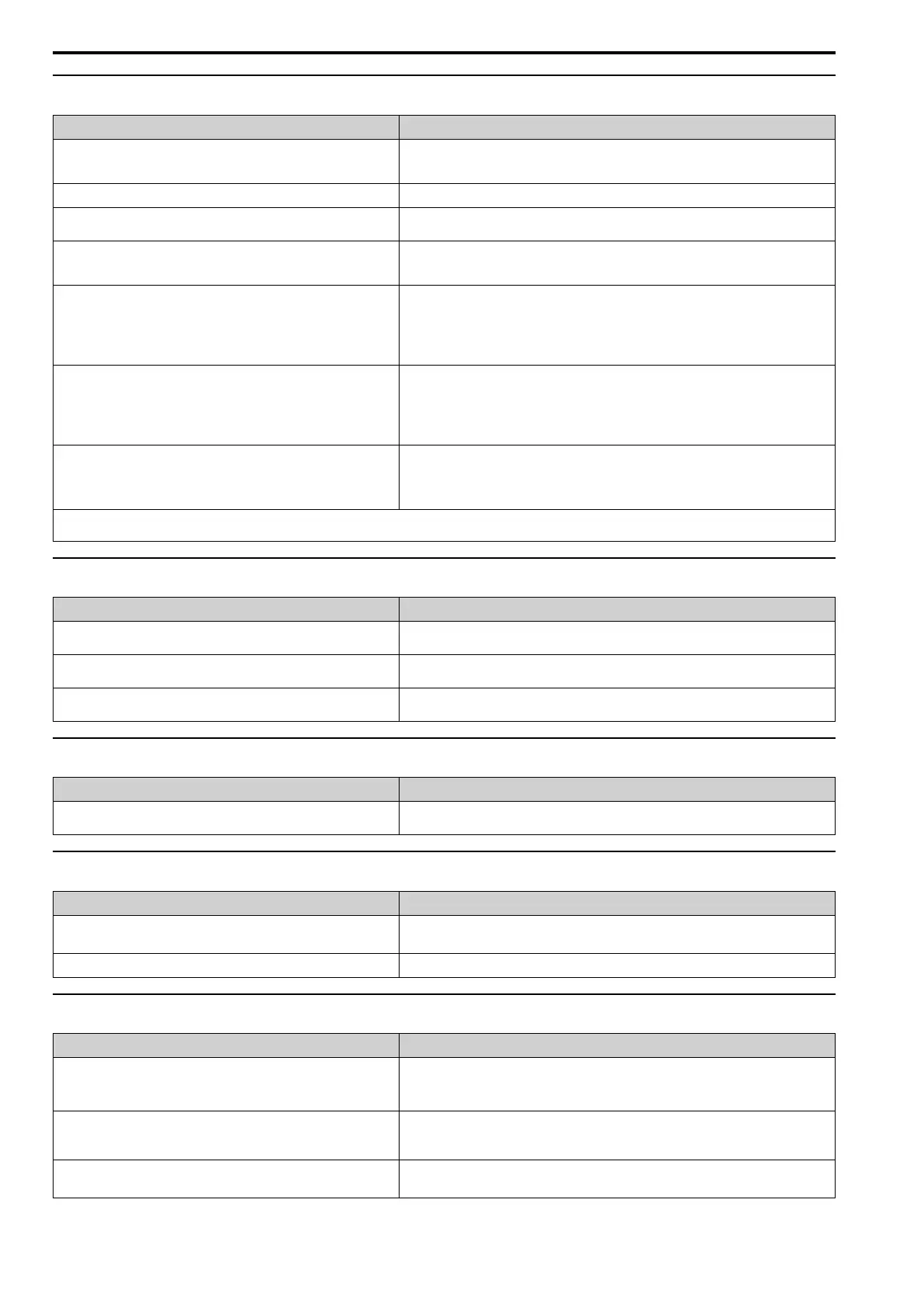

◆ Load Slips at Start

Causes Possible Solutions

The setting values of S1-05 [Brake Release Current (FWD)], S1-06 [Brake

Release Current (REV)], S1-07 [Brake Release Torque (FWD)], and S1-08

[Brake Release Torque (REV)] are too low.

Increase the setting values of S1-05 to S1-08.

The V/f setting is too low. Increase the V/f setting.

The setting value of C4-02 [Torque Compensation Delay Time] is too high

while using Open Loop Vector Control.

Set C4-02 ≒ 20 [20 ms].

The setting value of S1-09 [Torque Compensation (FWD)] (the amount of

torque forcing) is too low while using Open Loop Vector Control, Closed

Loop Vector Control, or Advanced Open Loop Vector Control.

Set S1-09 ≒ 50 to 80 [50% to 80%].

The output current is more than 125% of the rated current while using

Closed Loop Vector Control or Advanced Open Loop Vector Control.

Do these procedures to solve problems with starting up magnetic flux.

• Set b2-03 = 0.2 to 0.3 [DC Inject Braking Time at Start = 0.2 s to 0.3 s].

• Set d6-03 = 1 [Field Forcing Selection = Enabled] and d6-06 = 200 to 400 [Field Forcing

Limit = 200% to 400%].

• Do the initial excitation process.

The output current is more than 125% of the rated current while using Open

Loop Vector Control.

Do these procedures to solve problems with starting up magnetic flux.

• Set b2-03 = 0.2 to 0.3 [DC Inject Braking Time at Start = 0.2 s to 0.3 s].

• Set b2-08 = 100 to 200 [Magnetic Flux Compensation Value = 100% to 200%].

• Increase the setting value of E1-08 [Mid Point A Voltage] to around 20 V maximum (40 V for

400 V class drive).

The output current is more than 125% of the rated current while using V/f

Control.

Do these procedures to solve problems with starting up magnetic flux.

• Set b2-03 = 0.2 to 0.3 [DC Inject Braking Time at Start = 0.2 s to 0.3 s].

• Increase the setting value of E1-08 [Mid Point A Voltage] to around 20 V maximum (40 V for

400 V class drive).

Note:

Refer to “Magnetic Flux Compensation (Start-up Current Suppression)” on page

236 to solve problems in flux build up.

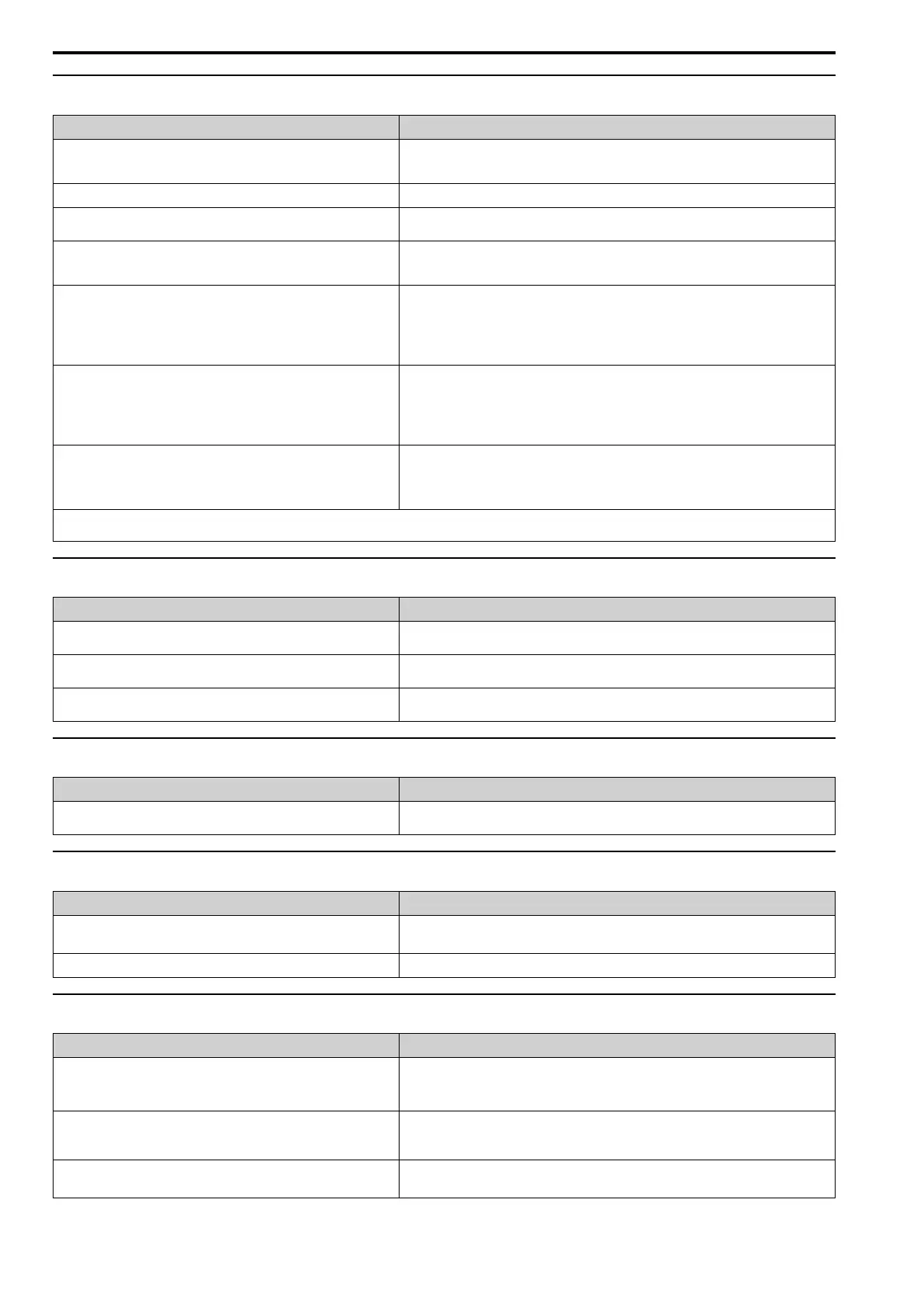

◆ Load Slips at Stop

Causes Possible Solutions

The setting value of S1-05 [Brake Release Current (FWD)] is too low while

using V/f control or OLV control.

Increase the setting value of S1-15.

The setting value of b2-04 [DC Inject Braking Time at Stop] is too low while

using Closed Loop Vector Control or Advanced Open Loop Vector Control.

Set b2-04 > 0.50.

Brake hold settings are not correct. Increase the setting values of S1-12 [Brake Hold Frequency (FWD)] and S1-13 [Brake Hold

Frequency (REV)].

◆ Slipping Occurs During Extremely Fast Inching

Causes Possible Solutions

Drive operation and brake operation do not keep up with the inching

operation.

Increase the setting value of S2-01 [Run Cmd Minimum On Time (FWD)] and S2-02 [Run Cmd

Minimum On Time (REV)].

◆ Load Falls When Brake Is Applied

Causes Possible Solutions

The open/close timing of the brake is incorrect. • Increase the value set in S1-14 [Slip Prevention Frequency].

• Increase the time set in S1-15 [Slip Prevention Time].

The DC injection braking is insufficient. Increase the value set in b2-02 [DC Injection Braking Current].

◆ Excessive Current Occurs at Start

Causes Possible Solutions

The brake sequence is not adjusted. • Decrease the setting values of S1-01 and S1-02 [Brake Release Frequency].

• Decrease the setting value of S1-03 [Brake Delay Frequency].

• Set S1-04 [Brake Delay Time] to align with the machine.

The motor flux build up is not enough while using Closed Loop Vector

Control or Advanced Open Loop Vector Control.

• Set d6-03 = 1 [Field Forcing Selection = Enabled] and d6-06 ≒ 200 to 400 [Field Forcing

Limit ≒ 200% to 400%].

• Do the initial excitation process.

Torque settings are too low while using Open Loop Vector Control, Closed

Loop Vector Control, or Advanced Open Loop Vector Control.

• Set L7-01 to L7-04 ≒ 150 [Torque Limit ≒ 150%].

• Set S1-07 ≒ 70 to 80 [Brake Release Torque (FWD) ≒ 70% to 80%].

Loading...

Loading...