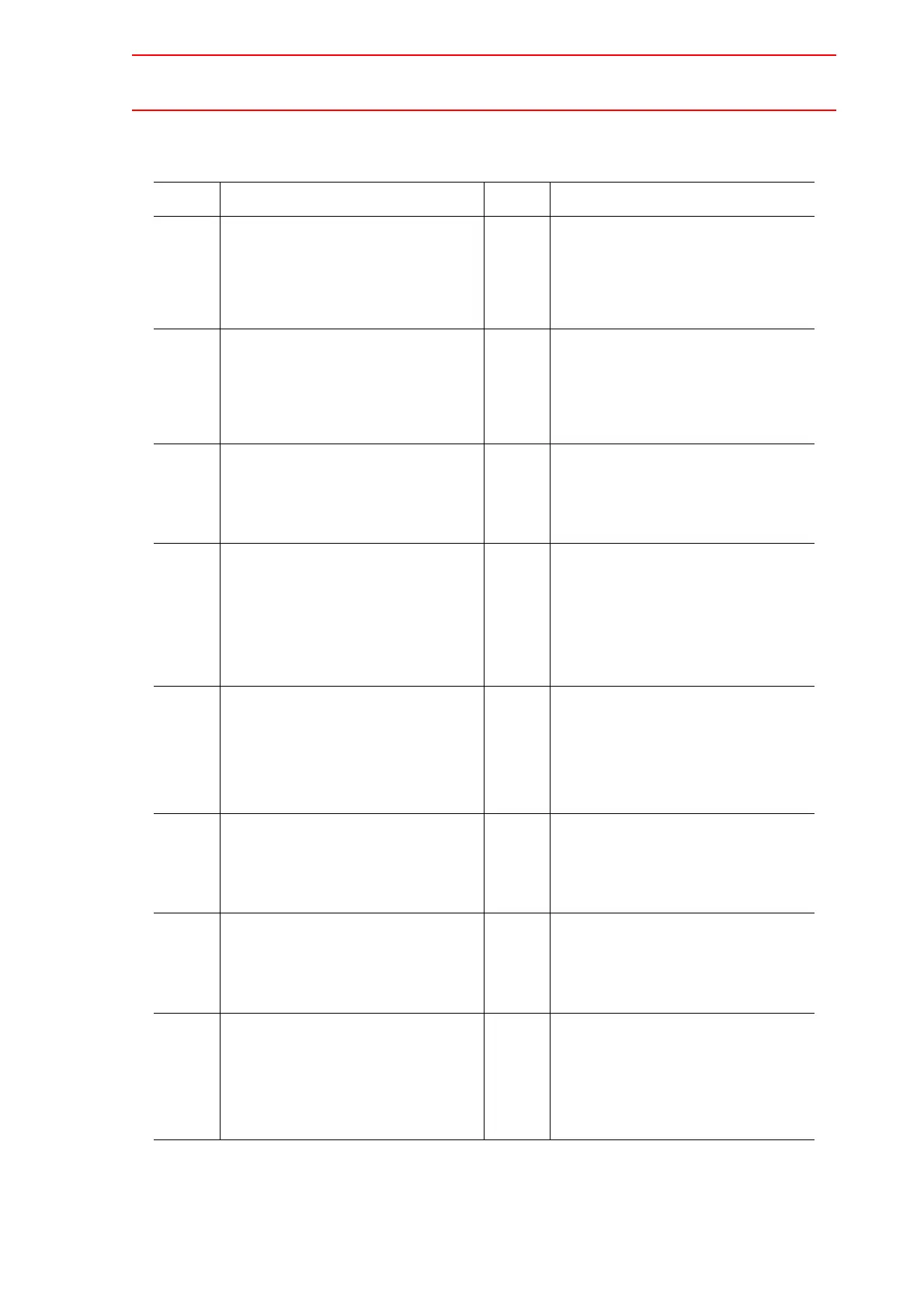

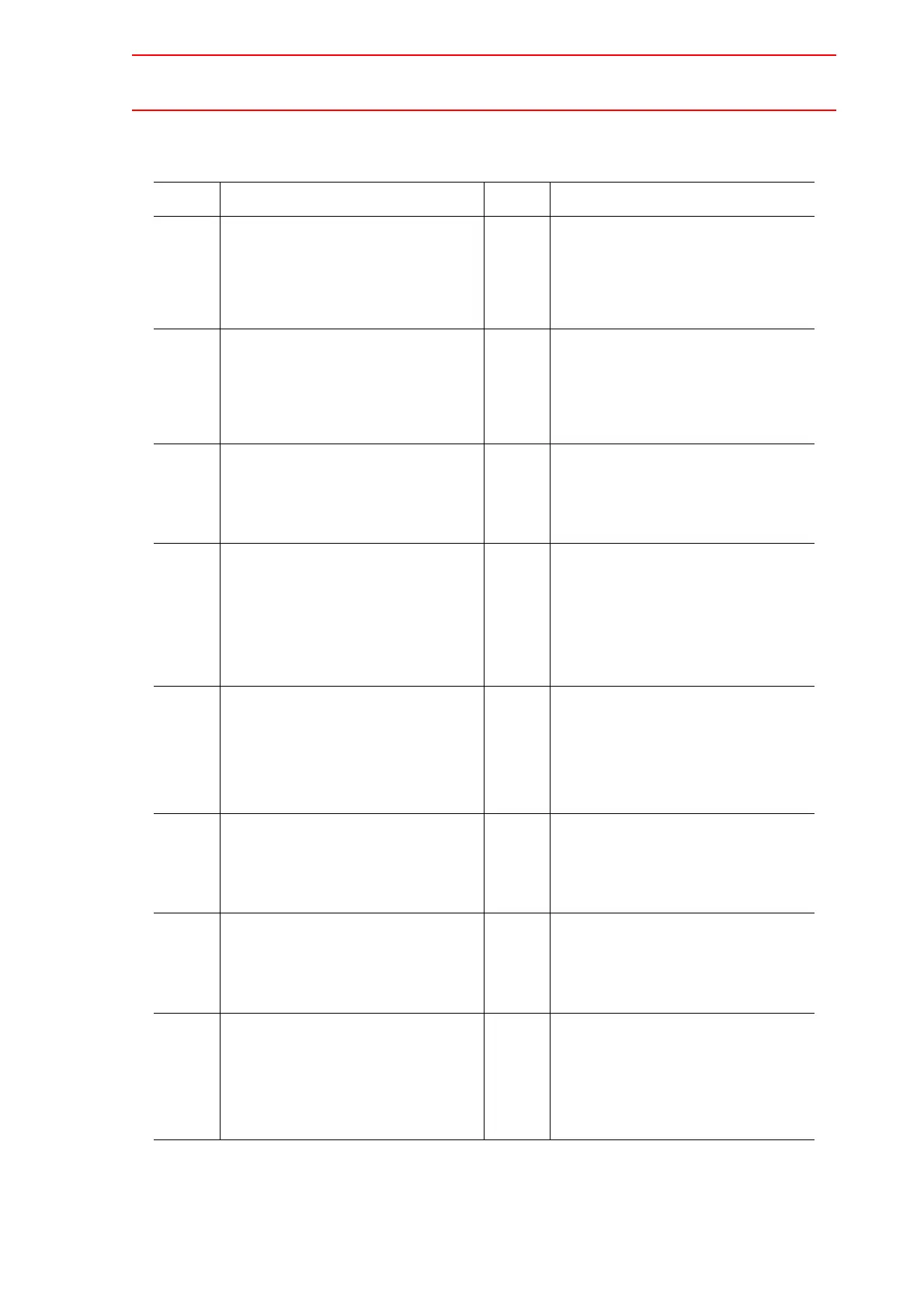

13.6 User I/O Signal Assignment

13-60

System Input List NIO01 (Spot Welding)

Logical

Number

Input Name / Function

Logical

Number

Input Name / Function

20010 EXTERNAL START

Functions the same as the [START] button in

the programming pendant. Only the rising edge

of the signal is valid. It starts robot operation

(playback). This signal is invalid if external start

is prohibited from the playback condition dis-

play.

20023 WELDING PAUSE (From sequencer)

This signal is used to move the manipulator to

the home position when an error occurs in the

Power Source or the gun.

The robot ignores the spot welding instruction

and operates playback motion.

20012 CALL MASTER JOB

Only the rising edge of the signal is valid. It

calls up the top of the robot program, that is the

top of the master job

*1

. This signal is invalid

during playback, during teach-lock and when

play master or call is prohibited (set from the

playback operation condition display).

20024 INTERFERENCE 3 ENTRANCE PROHIBITED

If the manipulator attempts to enter the cube

3

*2

area while this signal is ON, the manipula-

tor goes to wait status (with servo power ON).

During wait status, the manipulator operation

restarts if this signal turns OFF.

20013 ALARM/ERROR RESET

After an alarm or error has occurred and the

cause been corrected, this signal resets the

alarm or error.

20025 INTERFERENCE 4 ENTRANCE PROHIBITED

If the manipulator attempts to enter the cube

4

*2

area while this signal is ON, the manipula-

tor goes to wait status (with servo power ON).

During wait status, the manipulator operation

restarts if this signal turns OFF.

20015 SELECT PLAY MODE

The play mode is selected when the mode key

on the programming pendant is set at

"REMOTE". Only the rising edge of the signal

is valid. When this selection signal assigned

concurrently with other mode selection signal,

the teach mode is selected on a priority basis.

The signal is invalid while EXTERNAL MODE

SWITCH is prohibited.

20050

*4

TIMER COOLING WATER ERROR

This signal monitors the status of timer cooling

water. The manipulator displays alarm and

stops when this signal is input. The servo

power remains ON.

20016 SELECT TEACH MODE

The teach mode is selected when the mode

key of the programming pendant is set at

"REMOTE". The other mode selection is

unavailable when this signal is ON; the signal

is selected by priority even when the other

selection signal is ON, enabling the teach

mode selection.

20051

*4

GUN COOLING WATER ERROR

This signal monitors the status of gun cooling

water. The manipulator displays alarm and

stops when this signal is input. The servo

power supply remains ON.

20020 INTERFERENCE 1 ENTRANCE PROHIBITED

If the manipulator attempts to enter the cube

1

*2

area while this signal is ON, the manipula-

tor goes to wait status (with servo power ON).

During wait status, the manipulator operation

restarts if this signal turns OFF.

20052

*4

TRANSTHERMO ERROR

Error signal is sent from the transformer in the

gun to the robot. This signal is ON normally

(NC) and an alarm occurs when the signal is

OFF. The servo power supply remains ON.

20021 INTERFERENCE 2 ENTRANCE PROHIBITED

If the manipulator attempts to enter the cube

2

*2

area while this signal is ON, the manipula-

tor goes to wait status (with servo power ON).

During wait status, the manipulator operation

restarts if this signal turns OFF.

20053

*4

LOW AIR PRESSURE

When air pressure is reduced and this input is

turned ON, an alarm occurs. The servo power

supply remains ON.

20022 WELDING ON/OFF (From sequencer)

This signal inputs the welding ON/OFF selector

switch status from the sequencer in the inter-

lock unit. The WELD ON/OFF signal is output

to the Power Source according to this signal

and the manipulator status.

*3

WELD COMPLETION

This signal indicates that the Power Source

completed welding without error. This signal is

used as a confirmation signal for welding

instruction execution and manual spot welding.

After this signal is input, the welding sequence

is completed and the next step is executed

when confirmation limit switch is not provided.

Loading...

Loading...