Installation

Chillers

DeltaChill™ Air Cooled and FreeCool

Chiller Technical Manual 7267818 V1.13.0_01_2018

Installation Data

Positioning

The installation position should be selected with the following points in mind:

● Position on a stable and even base, levelled to ensure that the compressor operates correctly

● Levelling should be to +/- 5mm.

● Where vibration transmission to the building structure is possible, t spring anti-vibration mounts and exible water

connections.

● Observe airow and maintenance clearance.

● Pipework and electrical connections are readily accessible.

● Where multiple units are installed, due care should be taken to avoid the discharge air from each unit adversely

affecting other units in the vicinity.

● Within a side enclosed installation, the fan MUST be higher than the enclosing structure.

● Increase airow and maintenance clearances for side-enclosed or multiple unit applications.

● Allow free space above the fans to prevent air recirculation.

● Ensure that there is a safe access and operating area provided for unit controls.

Prior to connecting services, ensure that the equipment is installed and completely level.

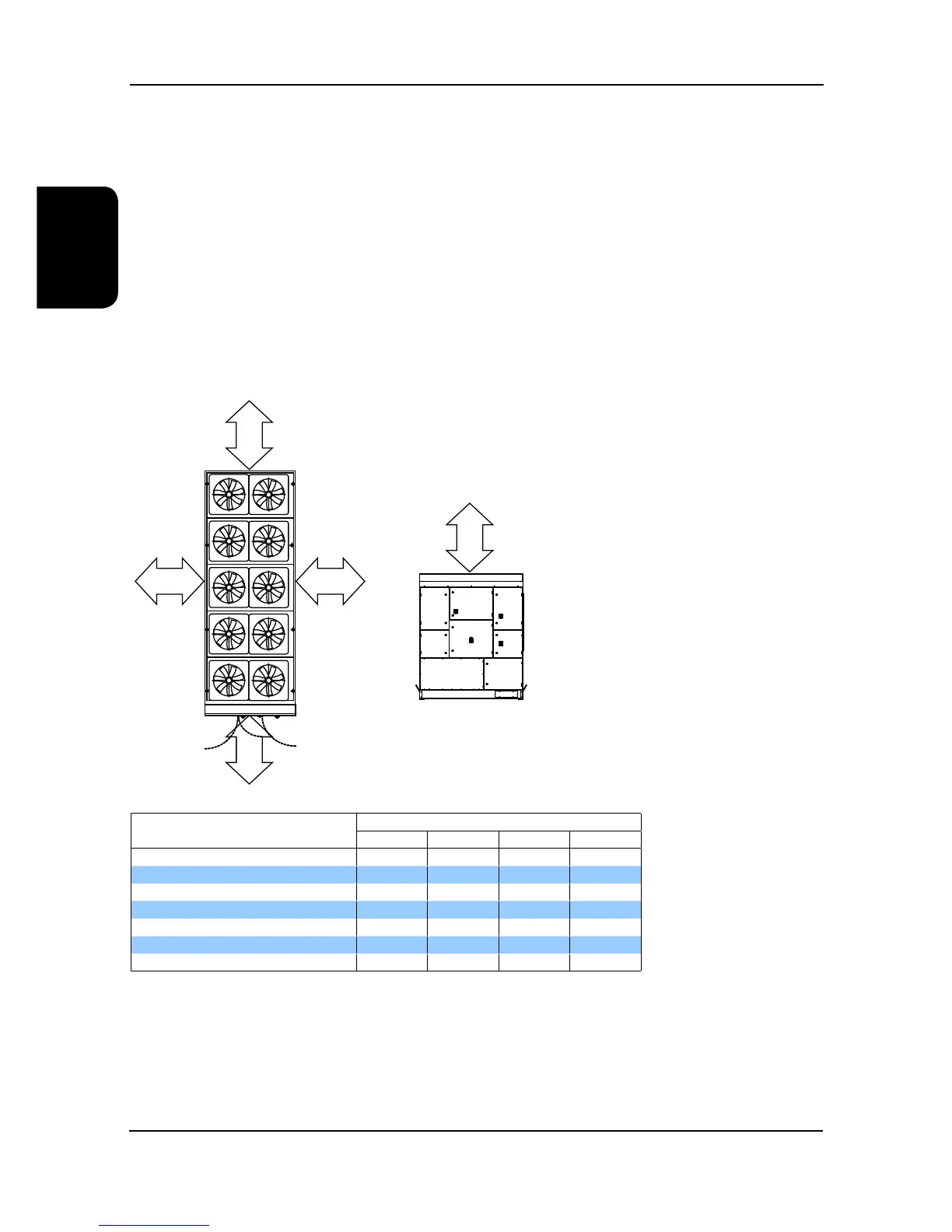

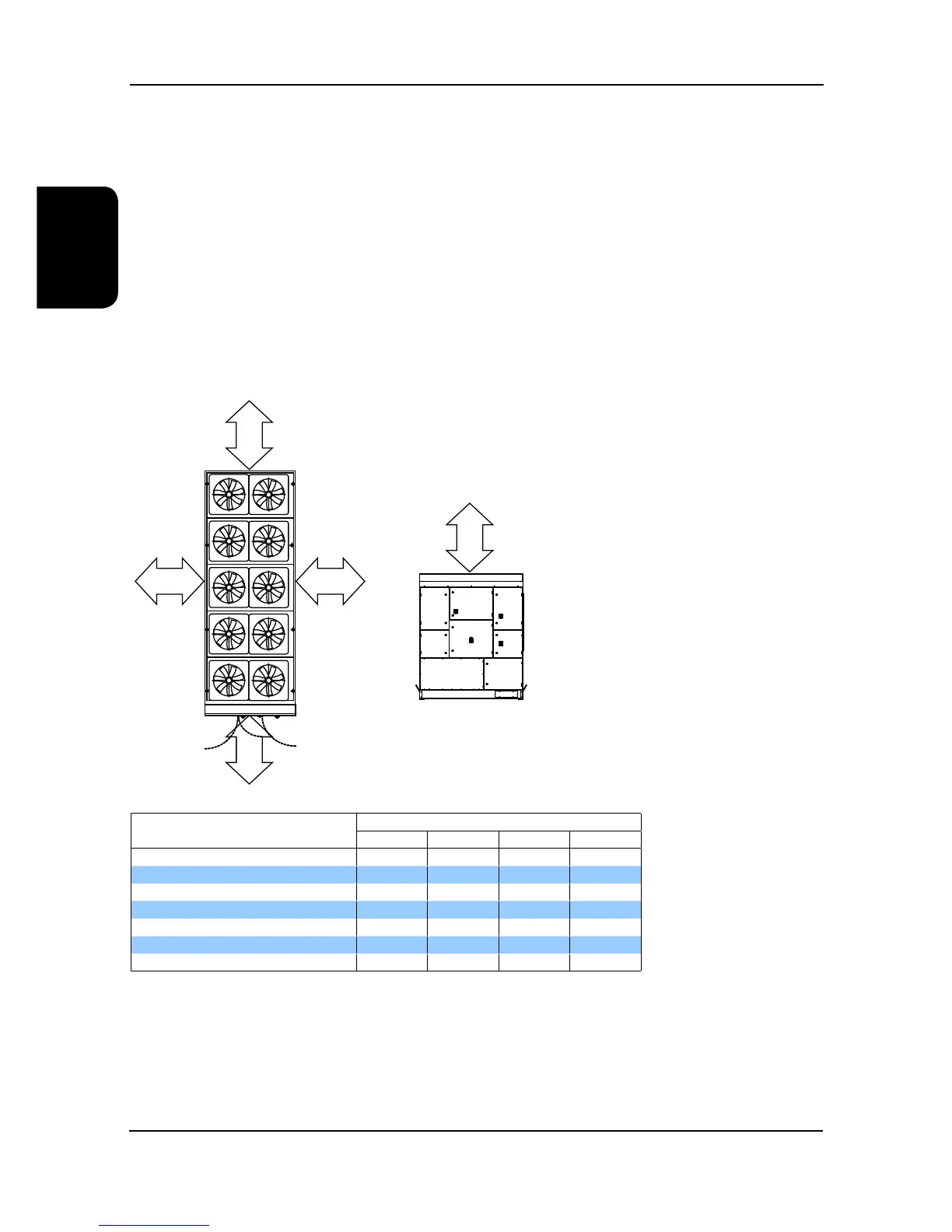

Airow & Maintenance Clearances

Application Distance from Overall Base Dimension (mm)

A B C D

Free of walls and overhang 1300 1300 1300 1300

Enclosed to A 2600 1300 1300 1300

Unit parallel with A 2600 1300 1300 1300

Enclosed to B 1300 2600 1300 1300

Unit in line with B 1300 1300 1300 1300

Unit in line with C Controls End 1300 1300 2600 1300

Enclosed to C 1300 1300 2600 1300

Installation Data

Anti Vibration Mounting (Optional)

Spring Type

Each mount is coloured to indicate the different loads, refer to instructions supplied for

correct allocation.

Dimensions

A(1) B C D E F

162 130 225 186 20 16

(1) Unloaded dimension

Components

1 Locating Screw

2 Retaining Nut & Washer

3 Levelling Screw

4 Levelling Lock Nut

5 Retaining Studs

6a Upper Retaining Nuts

6b Lower Retaining nuts

7 Spring assembly

8 Pressure Plate

9 Top Plate

10 Bolting-down holes

Installation

1. Locate and secure mount using bolting down holes (10) in base plate.

2. Ensure mounts are located in line with the unit base.

3. If applicable, remove compressor enclosure covers to allow access to mount fi xing holes

in the unit base.

4. Lock the upper retaining nuts (6a) to the underside of the top plate (9) before a load is

applied.

5. Slacken levelling lock nut (4). (the levelling screw will not move if this is not slackened)

6. Remove retaining nut and washer (2), lower the unit onto the mounts and replace retaining nut and washer.

Beginning with the mount with the largest defl ection adjust the height of each mount using the levelling screw (3).

Mountings must be adjusted incrementally in turn.

Do not fully adjust 1 mount at a time as this may overload and damage springs.

When all mounts are level, lock each into place using the levelling lock nut (4)

Lock all retaining nuts (6a and 6b) to the extreme ends of the retaining studs (5)

Do not connect any services until all anti vibration mounts have been fully adjusted.

Loading...

Loading...