Design Data

Glycol

Glycol is recommended when a supply water temperature of +5°C or below is required or when static water can be

exposed to freezing temperatures (lower than 3°C Ambient). This is specied further in the environmental consideration

section at the front of this document.

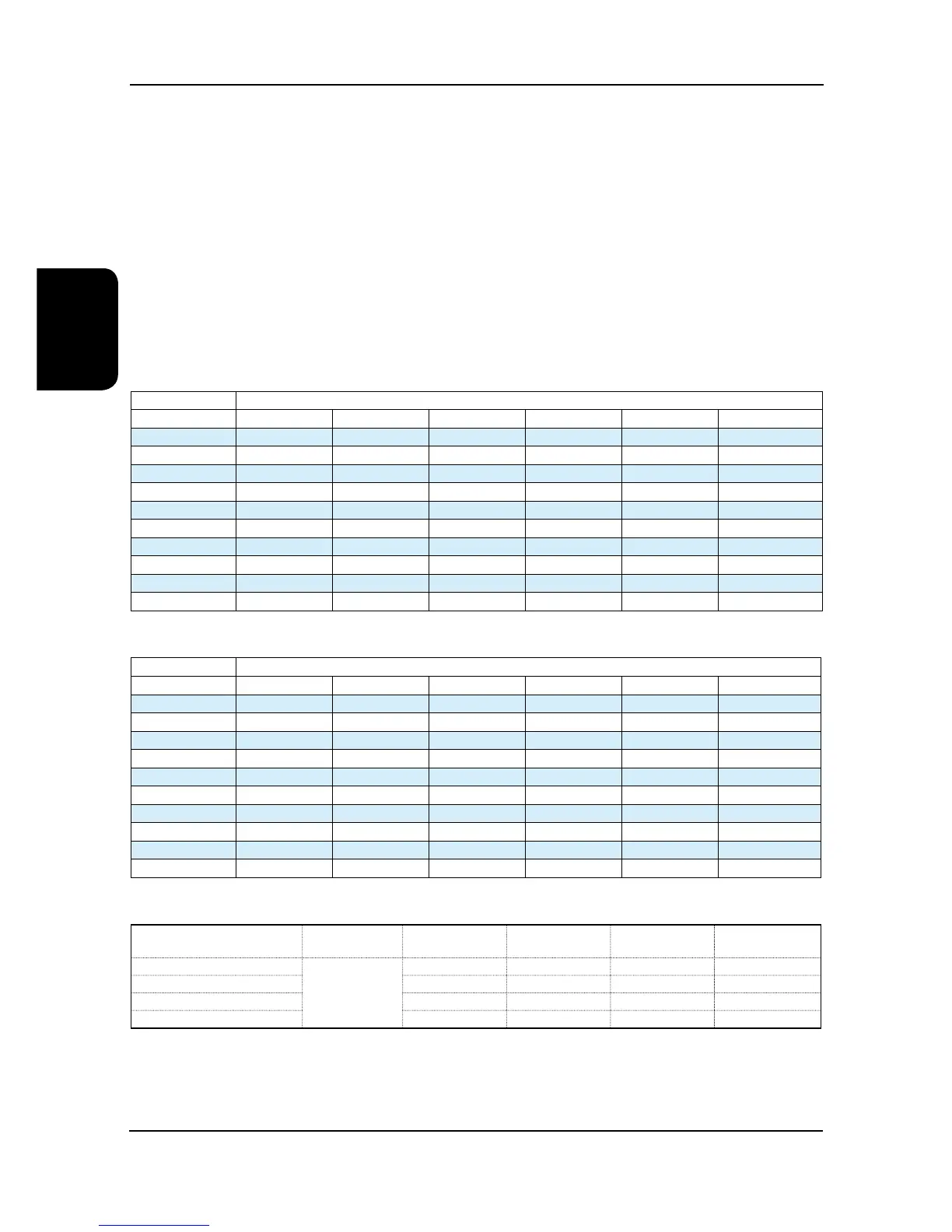

Glycol Percentage / Freezing Point

Temperature °C 0% / 0°C 20% / -7.8°C 25% / -10.7°C 30% / -14.1°C 35% / -17.9°C 40% / -22.3°C

0 4.21 3.77 3.68 3.59 3.50 3.40

5 4.20 3.78 3.69 3.60 3.51 3.42

10 4.19 3.79 3.71 3.62 3.53 3.44

15 4.19 3.80 3.72 3.63 3.54 3.45

20 4.18 3.82 3.73 3.65 3.56 3.47

25 4.18 3.83 3.74 3.66 3.57 3.49

30 4.18 3.84 3.76 3.67 3.59 3.50

35 4.18 3.85 3.77 3.69 3.60 3.52

40 4.18 3.86 3.78 3.70 3.62 3.54

45 4.18 3.87 3.79 3.72 3.63 3.55

Glycol Percentage / Freezing Point

Temperature °C 0% / °C 20% / -7.1°C 25% / -9.6°C 30% / -12.7°C 35% / -16.4°C 40% / -21.1°C

0

999.8 1035.7 1043.7 1051.8 1059.3 1066.8

5

999.9 1034.4 1042.4 1050.3 1057.8 1065.2

10

999.7 1032.9 1040.9 1048.8 1056.1 1063.5

15

999.0 1031.4 1039.2 1047.1 1054.4 1061.7

20

998.2 1029.7 1037.5 1045.3 1052.5 1059.7

25

997.0 1027.9 1035.6 1043.3 1050.5 1057.6

30

995.6 1026.0 1033.6 1041.3 1048.3 1055.4

35

994.0 1024.0 1031.5 1039.1 1046.1 1053.1

40

992.2 1021.8 1029.3 1036.8 1043.7 1050.6

45

990.2 1019.6 1027.0 1034.4 1041.2 1048.1

Ethylene Glycol Specic Heat

Ethylene Glycol Density

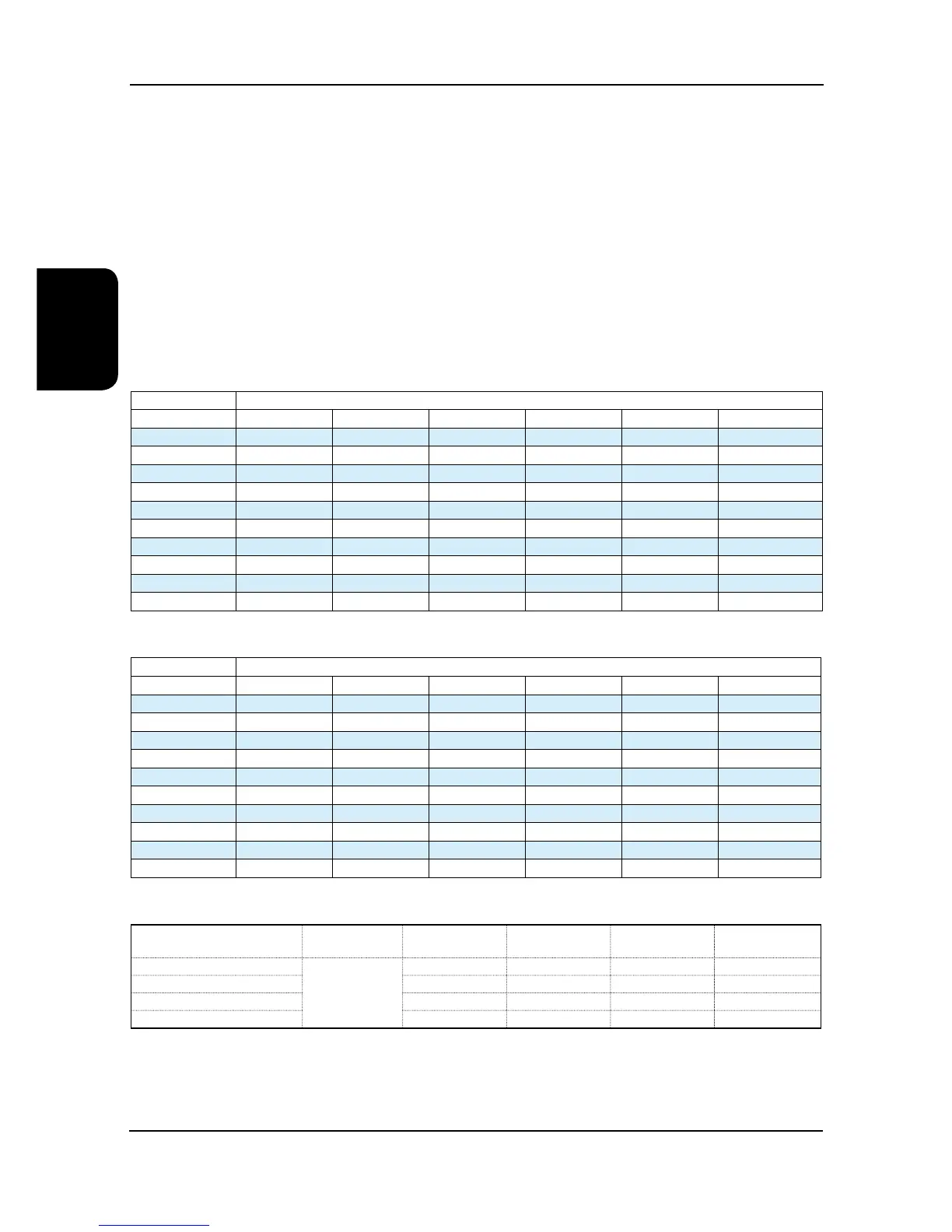

Kw =ρ x m x Cp x ∆t

Where

kW = Cooling Performance (KW)

ρ = Density of cooling medium (kg/m³)

m = mass flow of cooling media (kg/s)

Cp = Specific heat Capacity (kj/kg K)

∆t = Temperature difference between Inlet and Outlet (K)

Glycol in System /

Freezing Point ºC

10% / -4°C 20% / -9°C 30% / -15°C 40% / -23°C

Cooling Duty

Catalogue

Data x by:

0.98 0.97 0.95 0.93

Input Power 0.99 0.98 0.96 0.95

Water Flow 0.99 1.02 1.04 1.07

Pressure Drop 1.05 1.20 1.38 1.57

Correction Factors

Loading...

Loading...