3. Open and Close the target Deck, and check that the floating of paper is appropriate.“About Air Pressure of the Deck

Flotation Fan” on page 189

If the air pressure is too strong or too weak, change the value again.

Adjustment the pressure of the Deck Separation Roller

■ Preparation

1. Release the lock to open the target Deck. “Releasing the Deck” on page 77

■ Procedure

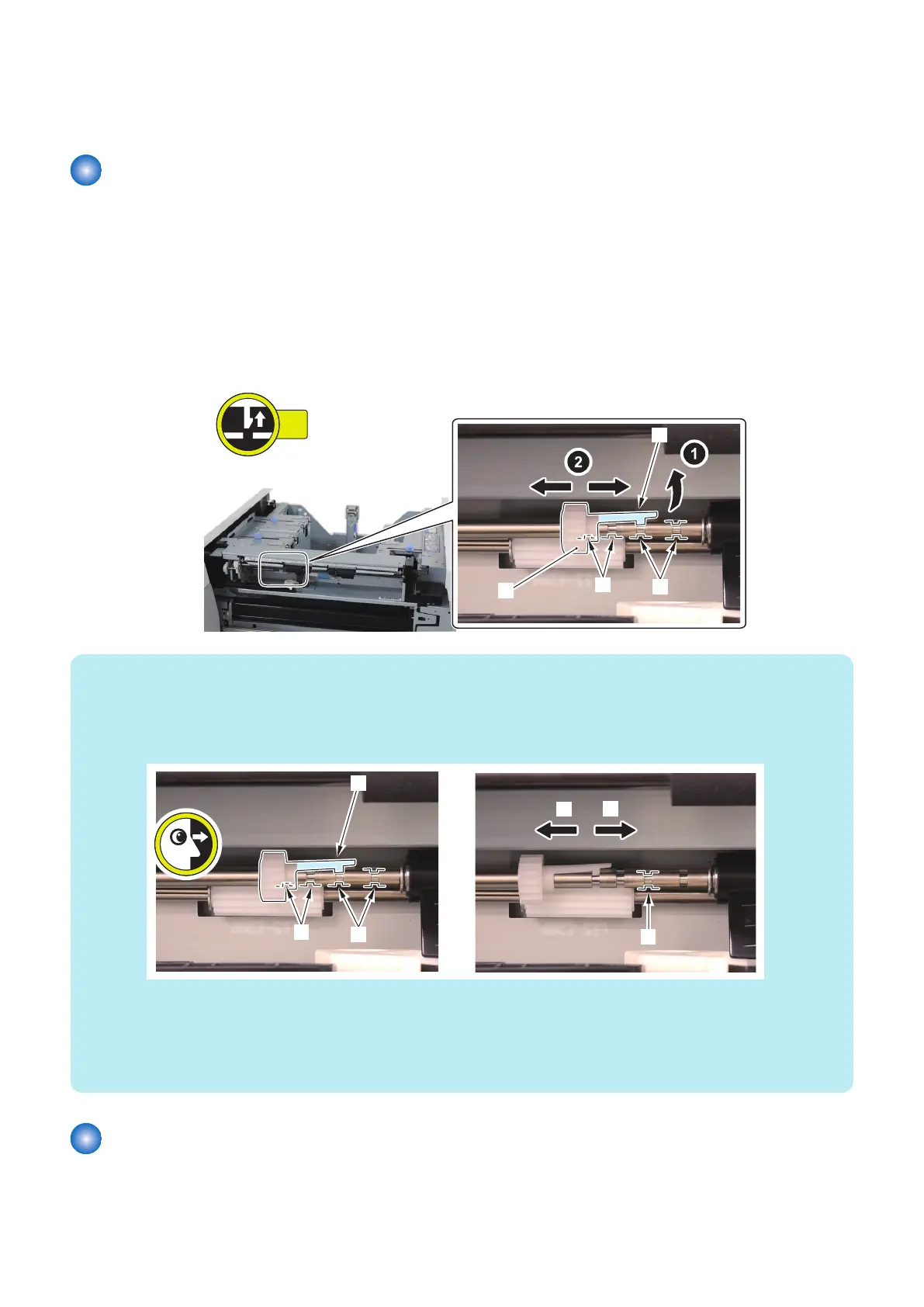

1. Move the Drive Transmission Gear [1] of the Deck Separation Roller.

• 1 Claw [2]

• 4 Grooves [3]

NOTE:

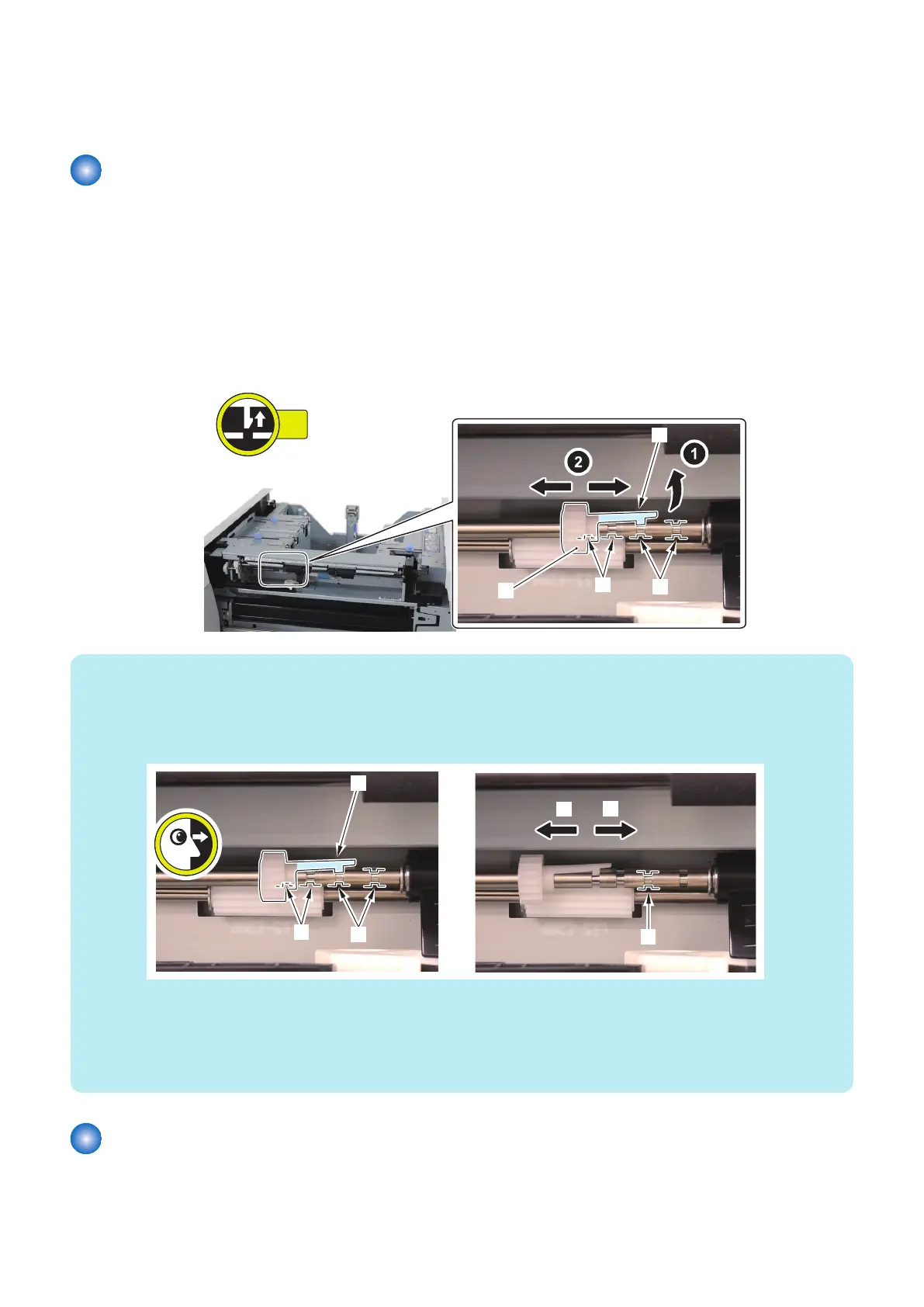

• After movement, make sure that the Claw [1] is in the Groove [2] of Shaft fully.

• When move the Drive Transmission Gear in direction [A], the pressure of the Deck Separation Roller is up.

• When move the Drive Transmission Gear in direction [B], the pressure of the Deck Separation Roller is down.

• At the time of shipment, the position of the Drive Transmission Gear is [C].

Case of up the pressure of the Deck Separation Roller

• When the pickup failure in the separation section occurs.

• When the double feeding occurs in the low frictional paper (coated paper, etc).

Case of down the pressure of the Deck Separation Roller

• When the double feeding occurs in the high frictional paper (plain paper, recycled paper, matt coated paper, etc).

Adjustment the pressure of the Deck Pickup Roller

■ Preparation

1. Release the lock to open the target Deck. “Releasing the Deck” on page 77

6. Troubleshooting

191

Loading...

Loading...