Page 296

REPAIR INSTRUCTIONS, PART 1

Do not force the piston. This indicates an

incorrectly aligned ring. Remove the piston

assembly, correct the problem, and then reinstall

it. Make sure the compressor tool remains in

contact with the cylinder sleeve until the piston

clears the tool. If contact is not maintained,

damage to the rings may result.

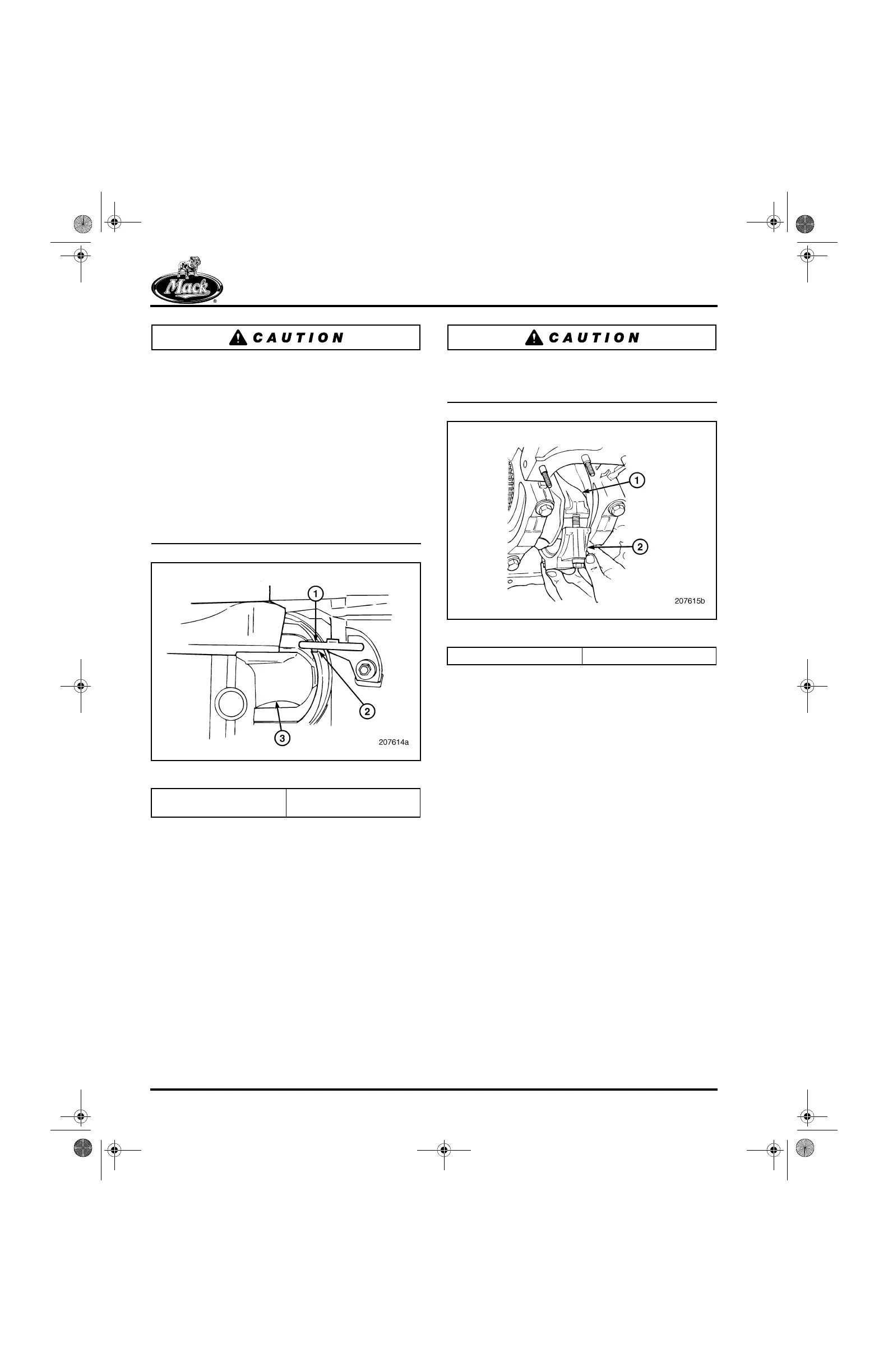

Before pushing the piston all the way down in the

sleeve, check to see that the piston cooling

nozzle is aligned with the nozzle clearance notch

provided in the lower end of the piston skirt as

shown in Figure 332. Damage to piston or spray

nozzle may result if it is not aligned.

332

Figure 332 — Piston Skirt/Cooling Nozzle Alignment

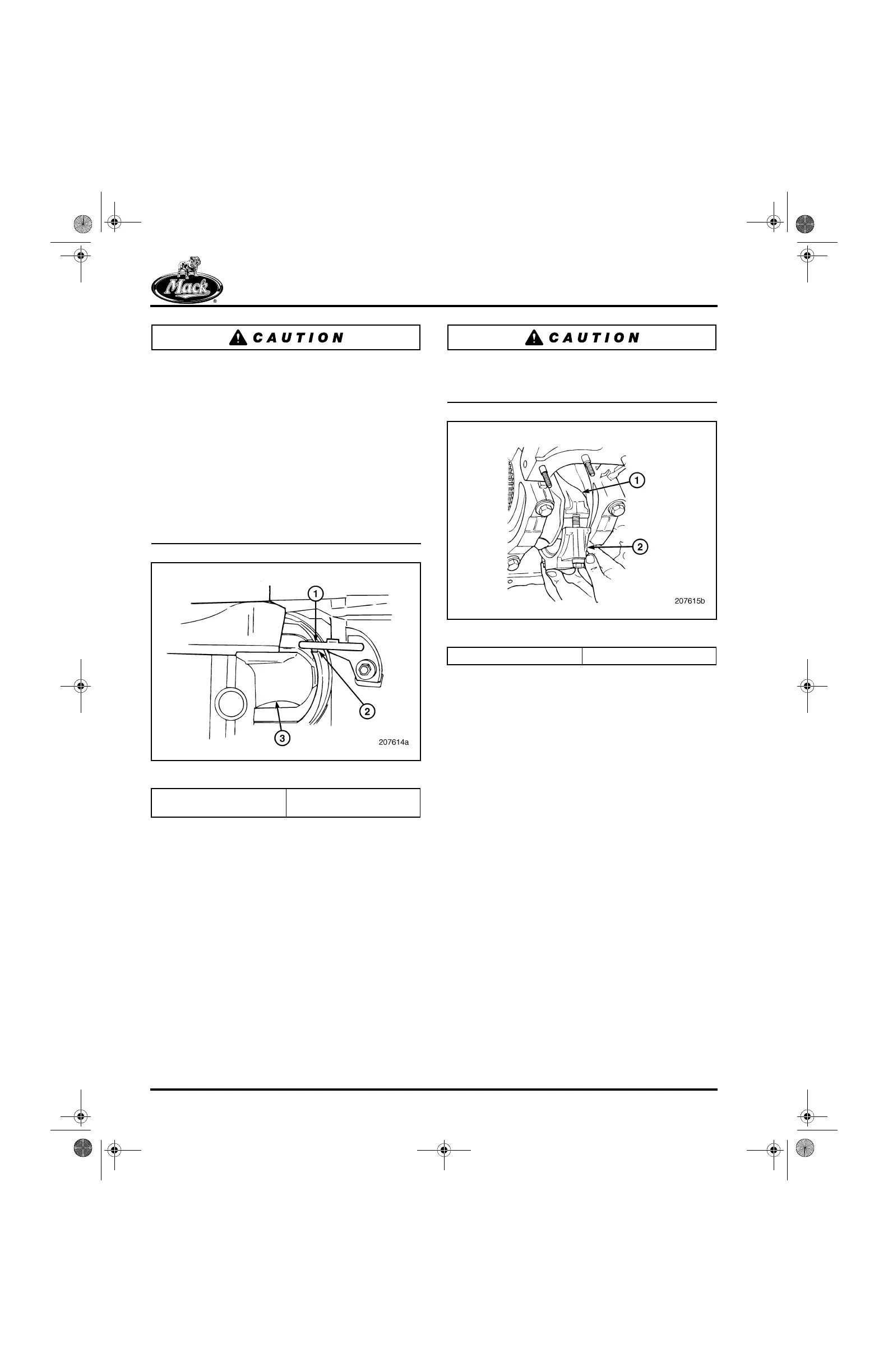

12. Align the rod with the crankshaft journal and

continue pushing the piston into the sleeve

while guiding the rod end to clear the piston

cooling nozzle and seat properly on the

crankshaft journal.

13. Ensure that the correct rod bearing lower

insert (matched to upper insert) and the

alignment sleeves are positioned in the

bearing cap.

14. Begin by installing the bearing cap at the

No. 1 connecting rod journal (Figure 333)

and check Running Clearance following the

procedure later in this section. Repeat the

running clearance check following the

installation of each of the remaining five

pistons.

Running clearance must be checked after

installing each piston. Damage to the engine may

result if clearance is not within specification.

333

Figure 333 — Connecting Rod Cap Installation

15. Repeat the above steps to install the No. 6

piston.

16. Rotate the crankshaft so that the journals for

the No. 2 and No. 5 cylinders are at bottom

dead center and install the No. 2 and No. 5

pistons following the above steps.

17. Rotate the crankshaft so that the journals for

the No. 3 and No. 4 cylinders are at bottom

dead center and install the No. 3 and No. 4

pistons, again following the above steps.

RUNNING CLEARANCE CHECK

1. Place a section of Plastigage on the rod cap

bearing and place the cap and bearing in

position on the rod.

2. Apply a light coat of oil on the threads of the

rod cap capscrews and install the screws.

3. Angle torque the capscrews to 30 lb-ft

(41 N폷m) plus 90 degrees using torque angle

gauge set BT 91104, or equivalent.

1. Cooling Nozzle

2. Clearance Notch

3. Connecting Rod

1. Connecting Rod 2. Bearing Cap

5-111.bk Page 296 Monday, July 10, 2006 2:26 PM

Loading...

Loading...