Page 24

DESCRIPTION AND OPERATION

Exhaust gases exiting the EGR valve are hot,

near 1200°F (649°C). As such, the two tubes and

four clamps are made of stainless steel to provide

maximum service life. The hot tube section has

an integral bellows that allows for expansion and

contraction as engine temperatures change.

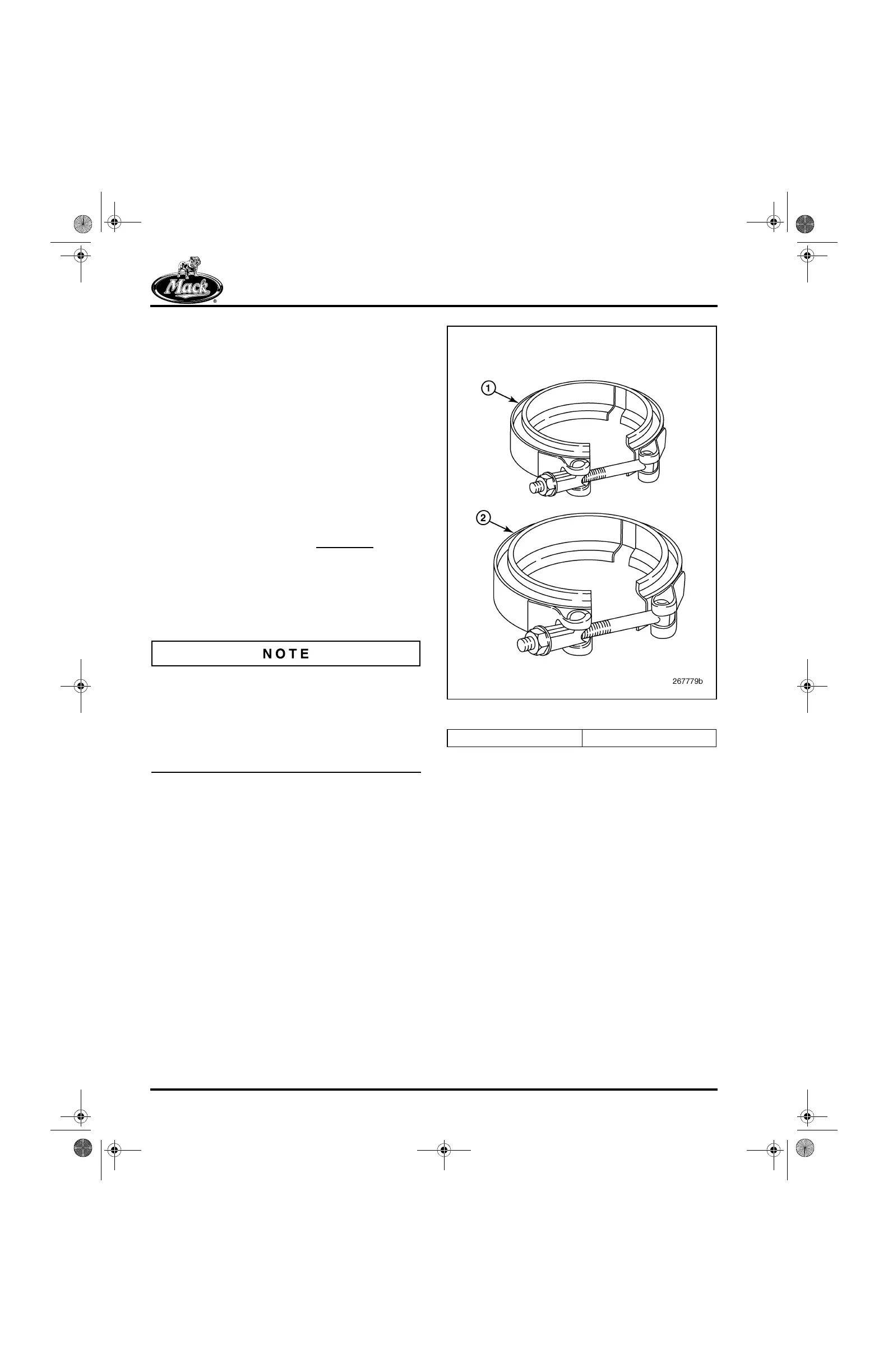

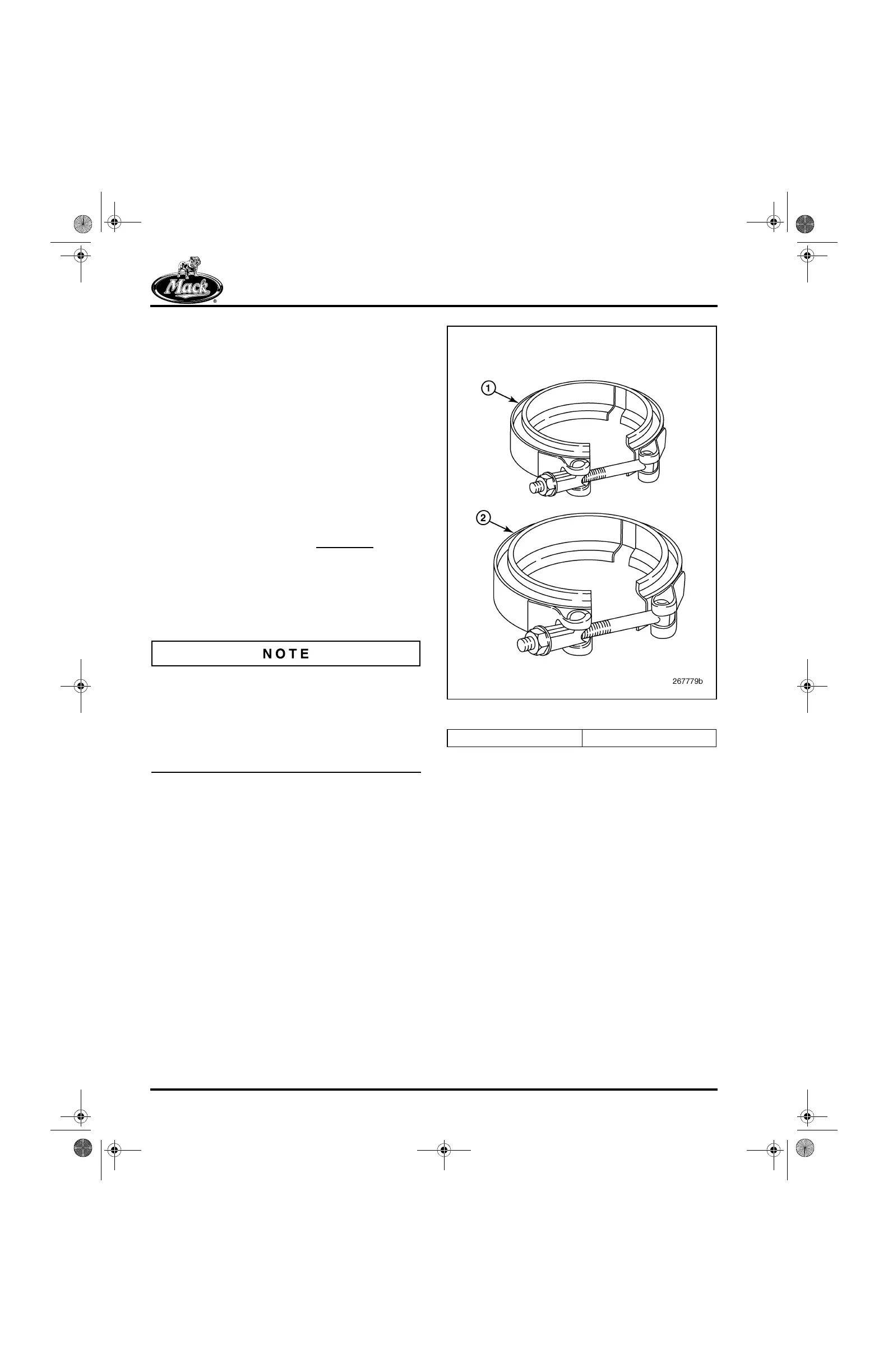

Wire-mesh O-rings along with V-band clamps

(Figure 13) are used for a gas-tight seal at the

tube connections. The V-band clamps are

different sizes depending on hot tube and cool

tube use, with the cool tube being the smaller of

the clamps. The seals are one-time use only and

must be replaced anytime a tube is removed in

service. Clamps used to connect the cool-side

tubes generally can be reused. However, for the

hot-side tube connections, the clamps can be

reused, but the T-bolt and nut should not

be

reused. Threads of the clamp bolts used in the

latter connections are prone to corrode in the

hotter environment. When removed for service,

the threads can be damaged making it impossible

to properly torque and get a gas-tight seal with

the new connection.

The EGR hot tube clamp retaining nut may gall

on the threads of the T-bolt at clamp removal.

Whenever a hot tube clamp has been in-service

and is removed, always install a new T-bolt and

nut. The EGR hot tube clamps should not be

replaced unless a clamp component, other than

the T-bolt and nut, is damaged.

13

Figure 13 — EGR Tube Clamps

1. Cool Tube Clamp 2. Hot Tube Clamp

5-111.bk Page 24 Monday, July 10, 2006 2:26 PM

Loading...

Loading...