Automatic Operation (Positioning Control)

7-6

7.1.4 Setting and Operation of P-Point Control

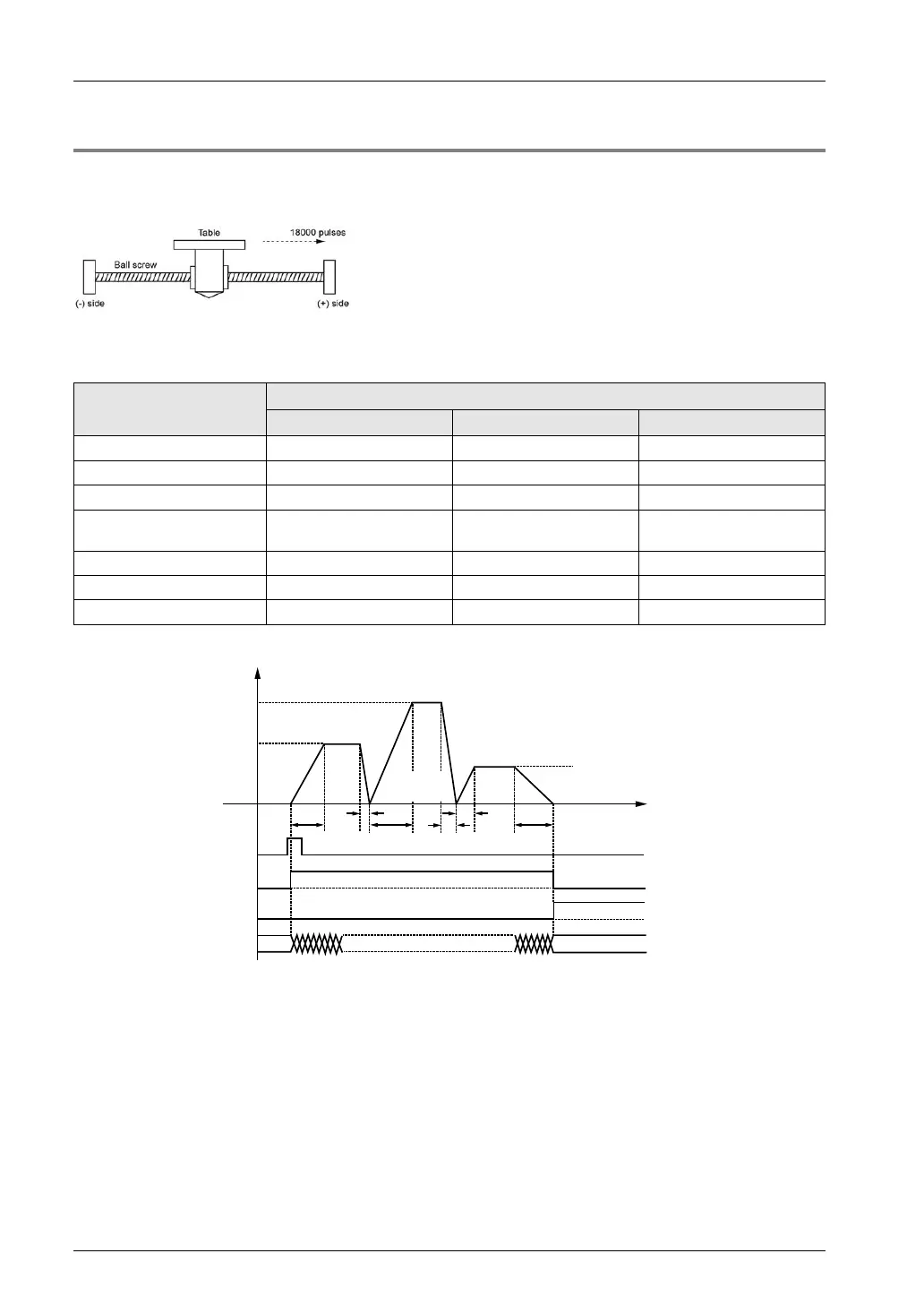

The example below is a case of single-axis control with the positioning unit installed in slot 1.

The movement amount setting uses an increment method in pulses.

Settings

Use the tool software to make positioning data and parameter settings. The unit is set to pulse.

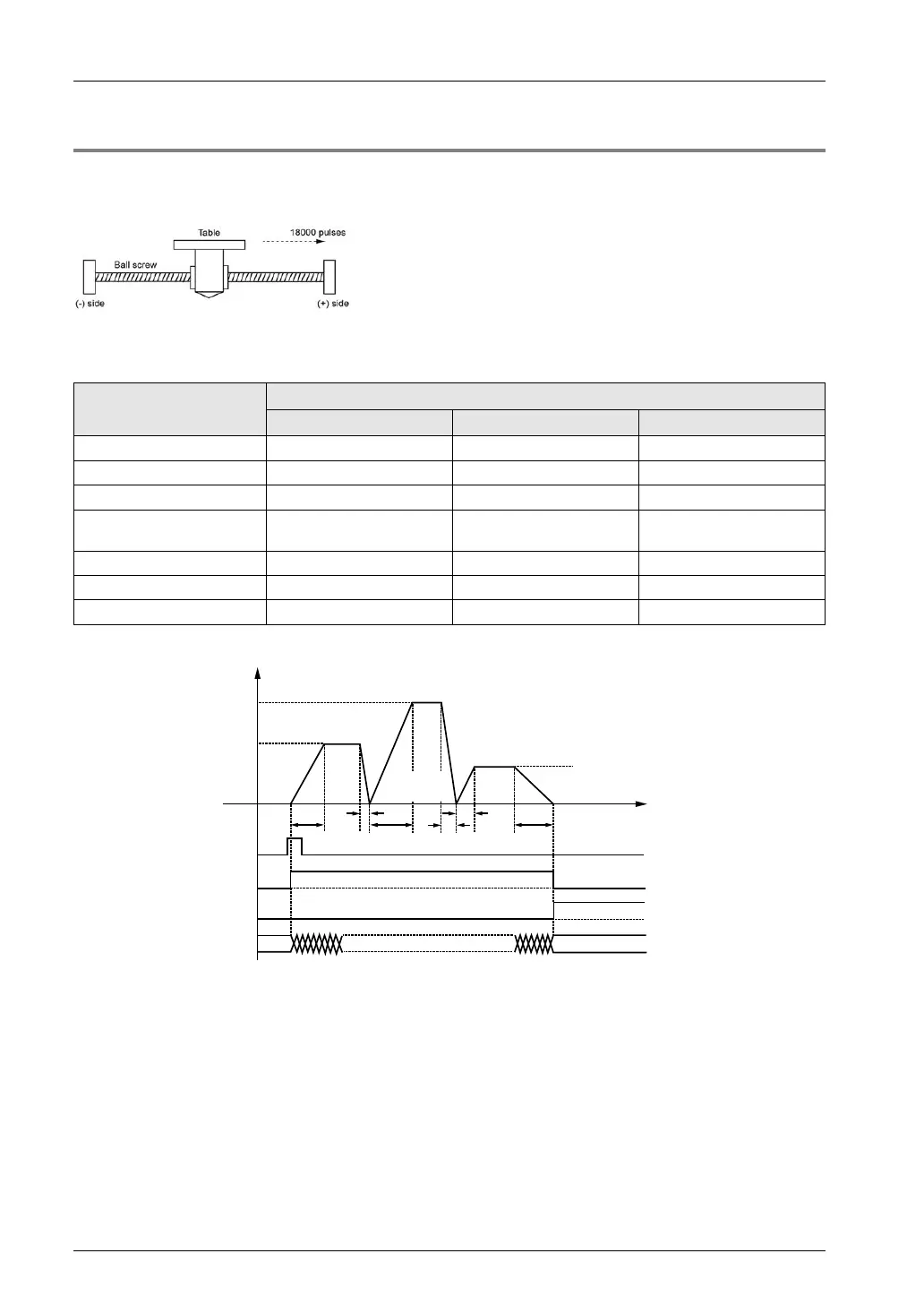

Items Setting example

Table 1 Table 2 Table 3

Operation pattern C: Continuance point C: Continuance point E: End point

Control method I: Increment I: Increment I: Increment

X-axis movement amount 5000 pulses 10000 pulses 3000 pulses

Acceleration/deceleration

pattern

L: Linear L: Linear L: Linear

Acceleration time (ms) 100 ms 200 ms 30 ms

Deceleration time (ms) 10 ms 20 ms 150 ms

Target speed 10000 pps 20000 pps 5000 pps

Operation diagram

100

f [pps]

10000

20000

5000

200

10

20

30

150

t [ms]

3800020000

Table 1

5000

pulses

Table 2

10000

pulses

Table 3

3000

pulses

Positioning start contact Y110

Current value

Operation done flag X120

BUSY flag X118

Operation of each contact

• The BUSY flag (X118), which indicates that the motor is running, will turn ON when the

positioning control starts, and it will turn OFF when the operation completes.

• The operation done flag (X120), which indicates the completion of operation, will turn ON

when the current operation is completed, and it will be held until the next positioning control,

JOG operation, home return, or pulser operation starts. The flag will turn ON after the

positioning unit transmits a reference for the target position.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...