PAPER FEED

SM 6-55 B121 Series/B259 Series

Detailed

Descriptions

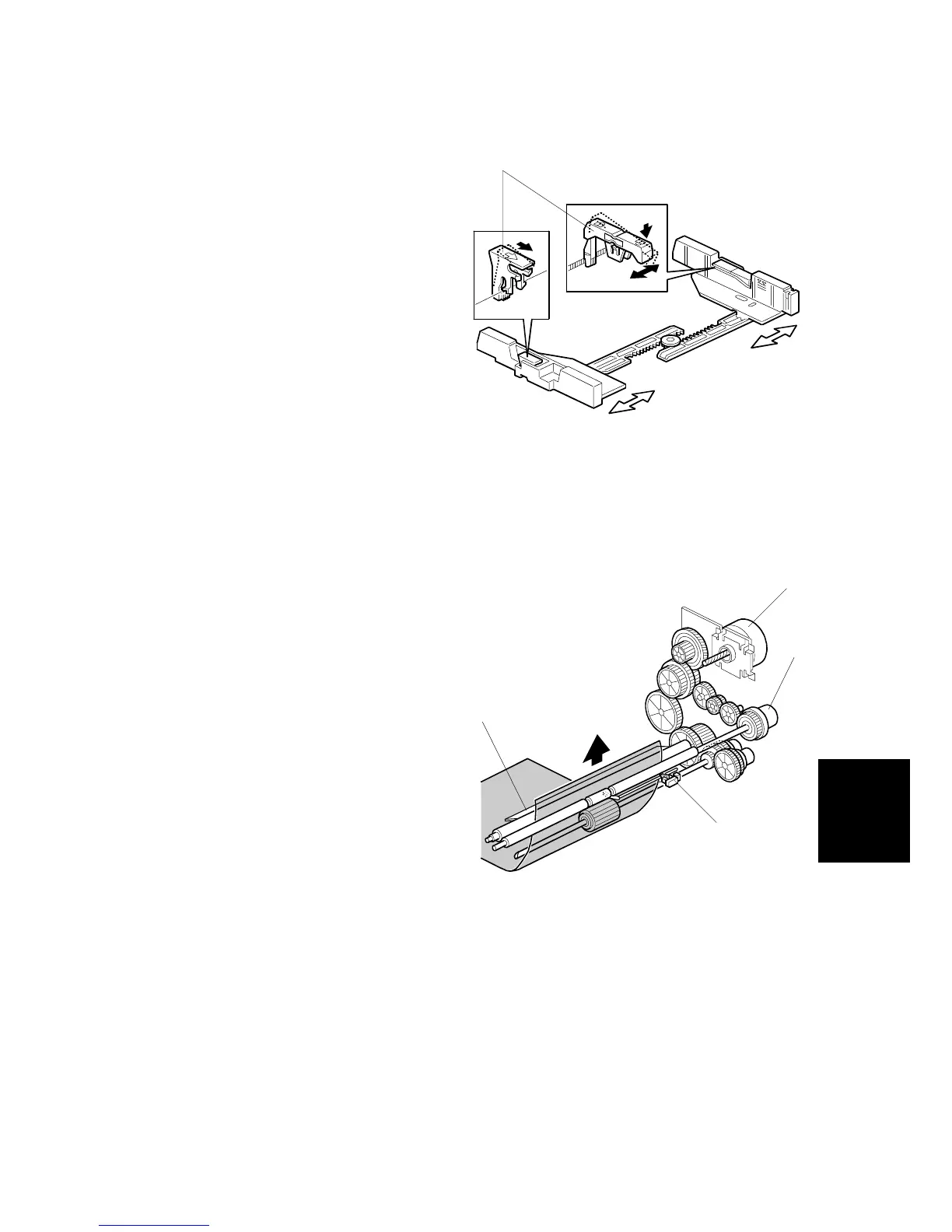

6.11.7 SIDE FENCES

If the tray is full of paper and it is

pushed in strongly, the fences may

deform or bend. This may cause the

paper to skew or the side-to-side

registration to be incorrect. To correct

this, each side fence has a stopper [A]

attached to it. Each side fence can be

secured with a screw, for customers

who do not want to change the paper

size.

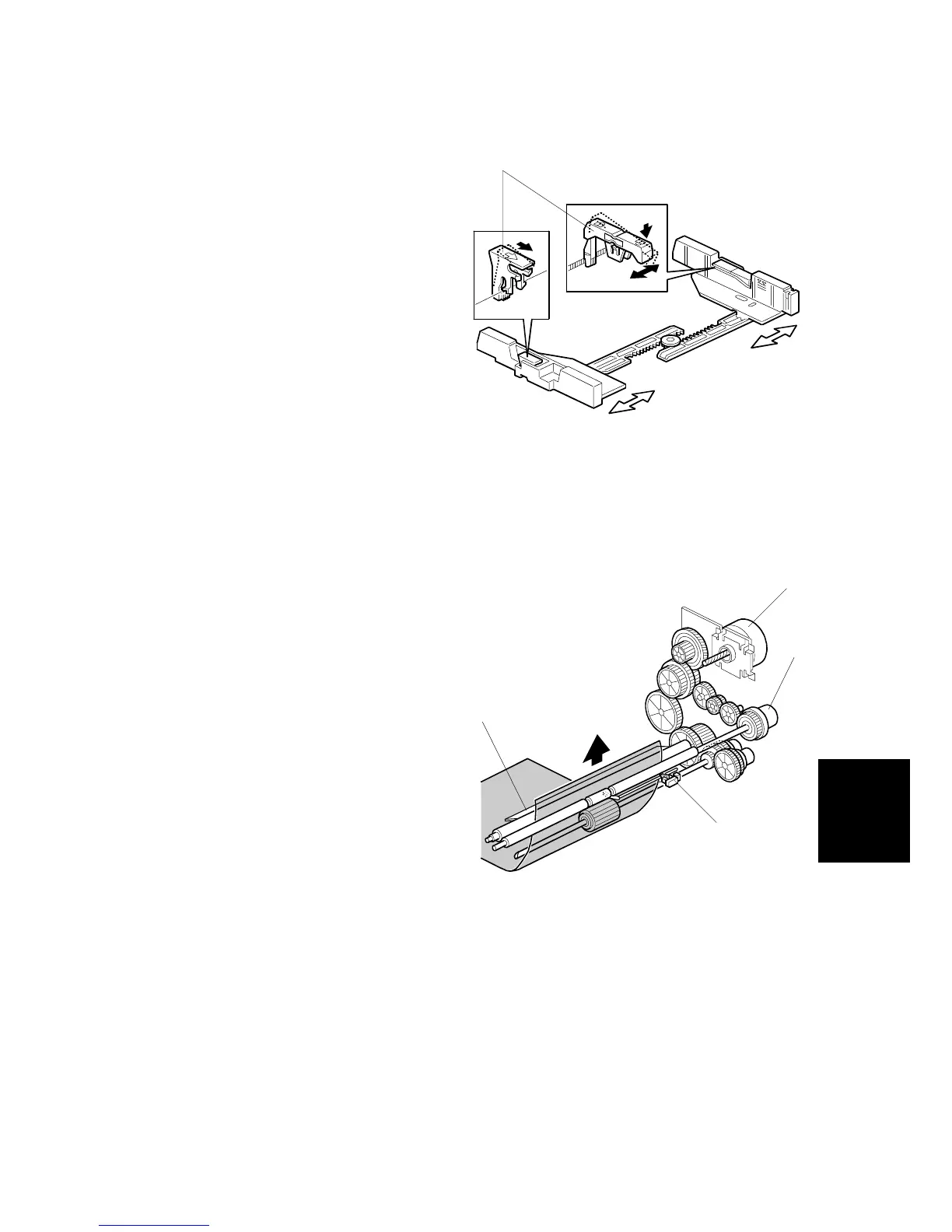

6.11.8 PAPER REGISTRATION

The drive from the main motor [A] is

transmitted to the registration roller

through the registration clutch gear [B].

The registration sensor [C] is used for

correcting paper skew and for

detecting paper misfeeds.

The cleaning mylar [D] contacts the

registration roller. It removes paper

dust from the registration roller so that

this dust will not transfer into the

development unit through the drum-

cleaning unit.

The amount of paper buckle at the

registration roller to correct skew can

be adjusted with SP1-003.

If jams frequently occur after

registration, SP1-903 can be used to activate the relay clutch so that the relay roller

assists the registration roller in feeding the paper along. When feeding from the by-

pass tray, the by-pass feed clutch is activated, turning the by-pass feed roller. This

feature may be needed when feeding thick paper, and cannot be used for the first

paper feed tray.

B121D960.WMF

B121D961.WMF

[A]

[A]

[D]

[C]

[B]

Loading...

Loading...