Start-up - Inspections before daily start-up

4 - 6

830 / 07.2012

Original operating instructions

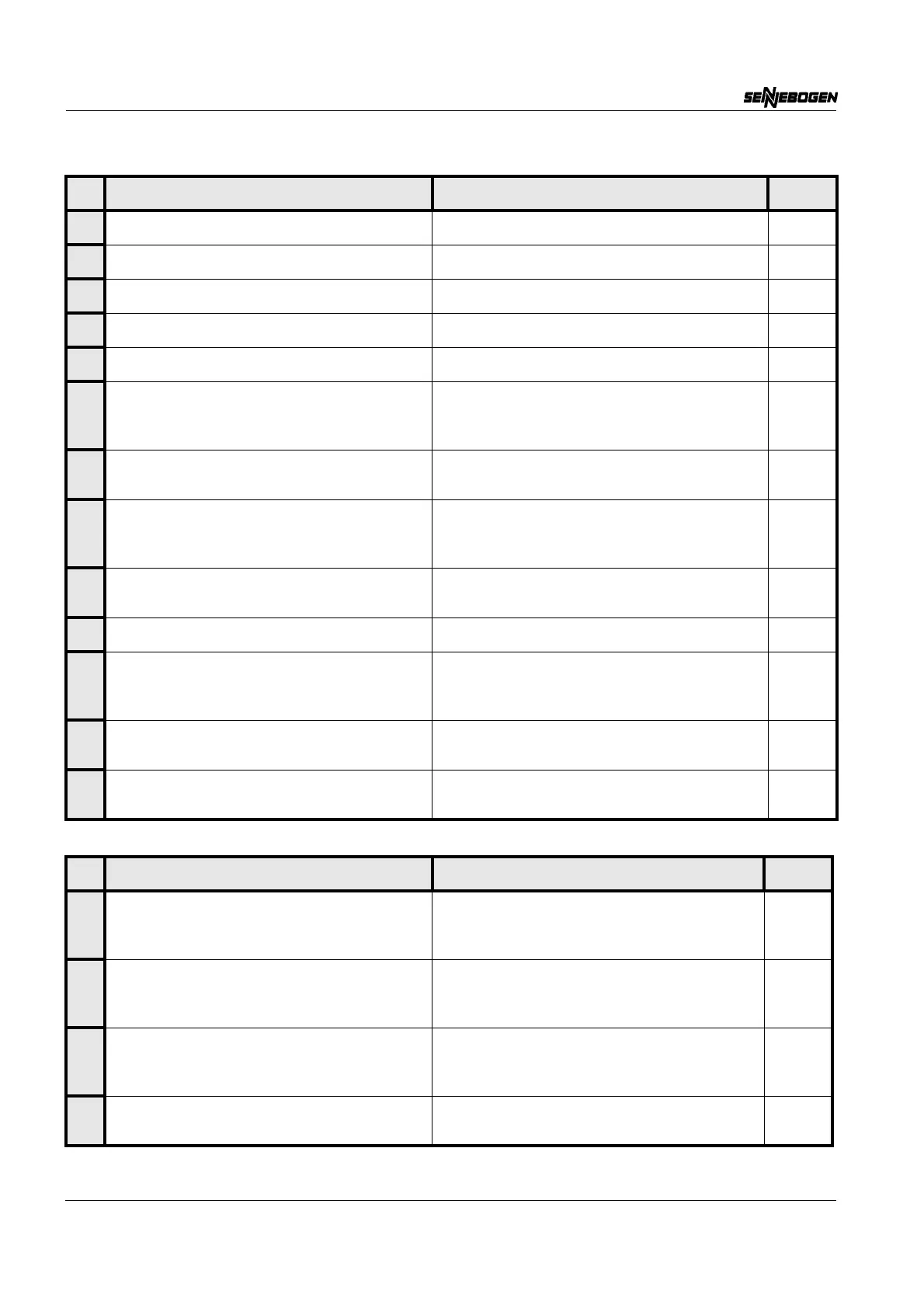

No.

Functional checks Steps to take

F1 Is the stick end limitation set correctly? If necessary, adjust

F2 Is the hoisting limiter set correctly? If necessary, adjust

F3 Is the overload warning device activated? If necessary, activate

F4 Is the machine positioned horizontally? If necessary, position correctly

F5 Is the stability of the machine ensured? If necessary, support properly

F6 Are all safety features (brakes, monitoring/

warning indicators, signal and lighting

equipment) working properly?

If necessary, locate and correct faults

F7 Are any warning or fault messages displayed

on the SENCON?

If necessary, locate and correct faults, read

fault log

F8 Are the electrical devices (windscreen wipers,

heating system, air conditioning system, etc.)

working correctly?

If necessary, locate and correct faults

F9 Is the emergency lowering feature of the cab

working?

If necessary, locate and correct faults

F10 Does the steering work properly? If necessary, adjust

F11 Is the central lubrication unit working? If necessary, refill with grease or locate and

correct faults (grease must appear at all

connected bearing points)

F12 Refrigerant, grease, diesel hydraulic oil,

cleaning water, pivoting gear.

Check/fill if necessary

F13 Lighting, rotating beacons, reverse signal,

camera

If necessary, replace

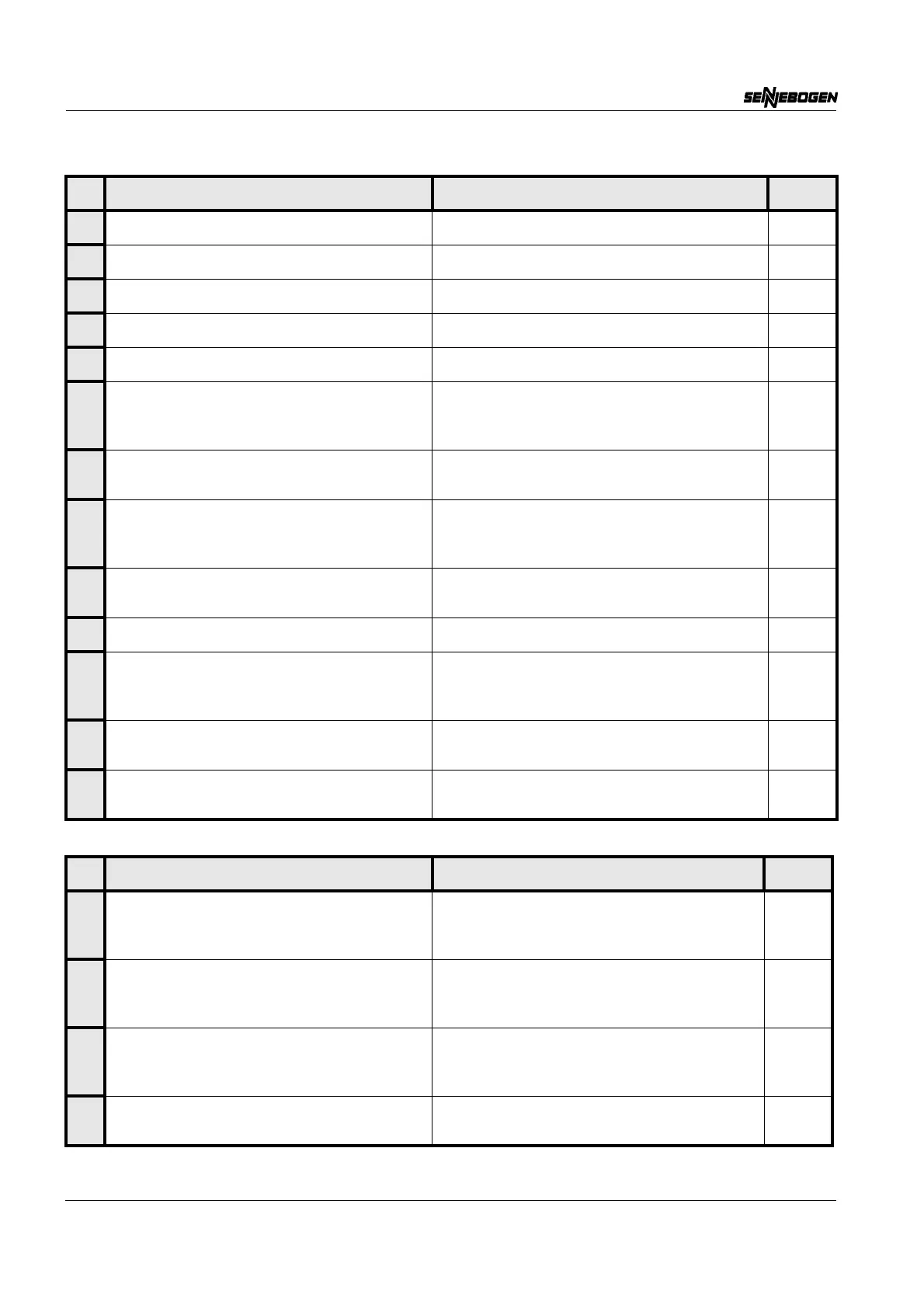

No.

Visual checks Steps to take

S1 Are all protective coverings, insulating

materials and warning signs in place on the

machine and undamaged?

If necessary, replace

S2 Are all access ladders, grips and anti-slip

surfacing in place and undamaged

(e.g. cracking)?

If necessary, repair or replace

S3 Is the machine clean enough to ensure no

danger areas exist due to dirt (danger of

slipping, falling, poor visibility)?

If necessary, clean using a high-pressure

cleaner. Exercise CAUTION around sensitive

or electrical components!

S4 Are the windows clean and free of ice and

snow?

If necessary, de-ice or clean

Loading...

Loading...