08/2005 Expanding the Operator Interface (BE1)

8 Terms, Tables, Lists, Examples

© Siemens AG, 2005. All rights reserved

SINUMERIK 840D sl/840D/840Di/810D HMI Installation and Start-Up Guide (IAM) – 08/2005 Edition

BE1/8-179

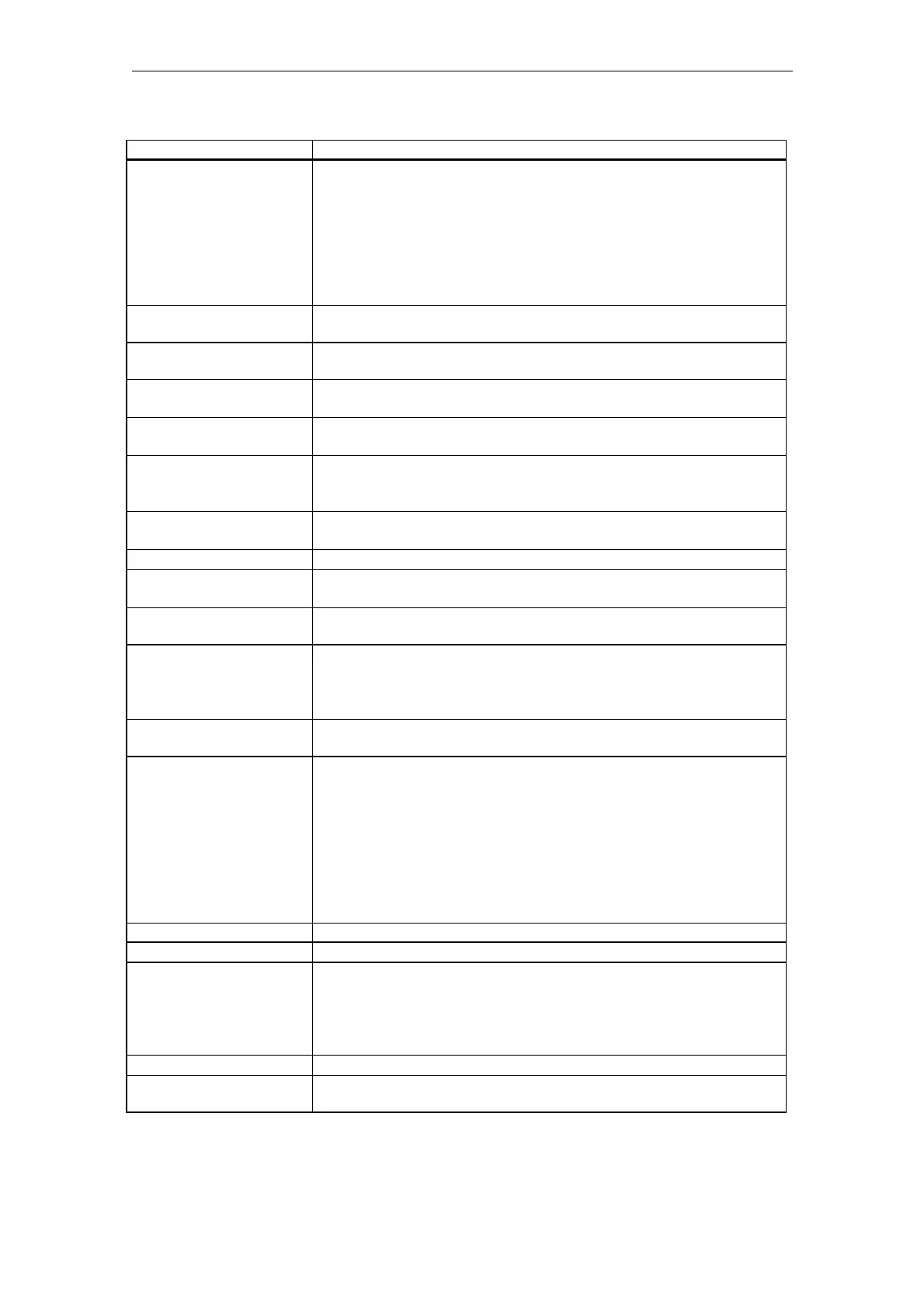

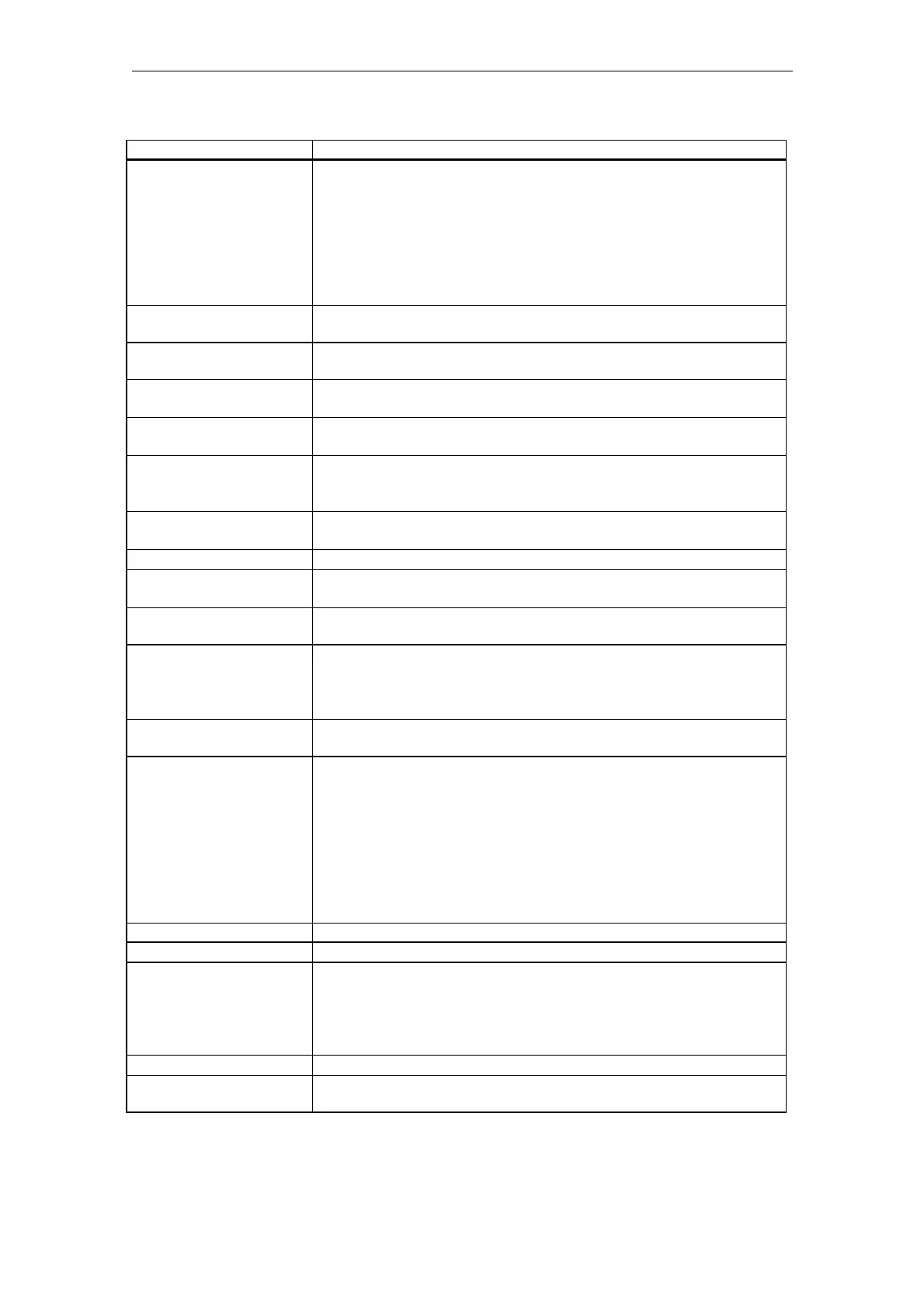

Term Explanation

Machine data Settings of properties of the SINUMERIK system made by

Siemens/machine manufacturer/end user and stored in the system.

The following types of auxiliary function are available:

$MN_... General NC machine data

$MC_... Channel-specific machine data

$MA_... Axis-specific machine data

$MM_... Machine data of operator panel front

In addition to this there is → setting data and drive machine data.

Main body of screen

form

Header, long text, graphics and → Screen form elements

ManualTurn Optimized SINUMERIK application and user interface for simple

turning machines.

Master screen form

→ Screen form, which calls another screen form but remains open

when a second screen is displayed.

Method Programmed sequence of operations, which is executed when a

corresponding → Event occurs.

NC Numerical Control: System component of a SINUMERIK system,

which controls the motional sequences of axes on the basis of →

Parts programs.

NC code

Permissible language elements used to write → Parts programs of

the SINUMERIK system

NC function

→ PI service

Parameters Parameters are variable elements of the programming syntax and

replaced by other words/symbols in the → Configuration file.

Parts program A program formulated in the NC language, which specifies motion

sequences for axes and various special actions.

PI service

→ Function, which, on an → NC, executes a clearly defined

operation.

PI services can be called from the → PLC and → HMI

Advanced/HMI Embedded.

PLC Programmable Logic Control: Programmable controller, which

performs mainly logic operations in the SINUMERIK system.

Programming support

system

Provision of → Screen forms to assist programmers in writing →

Parts programs with "higher-level" components

Free contour programming

Cycle support

Blueprint programming

→ Retranslation

→ Simulation

directly from the → Editor.

RECALL key Standard key on front of operator panel

Register

Memory for data exchange between → Screen forms.

Retranslation

Sections of → NC code can be generated in a → Parts program

from input fields in → Screen forms of the → Programming support

system. Recompilation is the reverse operation. The input fields,

which have created a selected section of NC code, are retrieved

from the NC code and displayed in the original screen form.

Screen form

Screen display of → User interface

Screen form definition

block

Program section from //M..........//END for defining a → Screen form

Loading...

Loading...