Commissioning HMI Advanced (IM4) 08/2005

2 Setting Functions and Parameters

© Siemens AG, 2005. All rights reserved

IM4/2-20 SINUMERIK 840D sl/840D/840Di/810D Installation and Start-Up HMI (IAM) - 08/2005 Edition

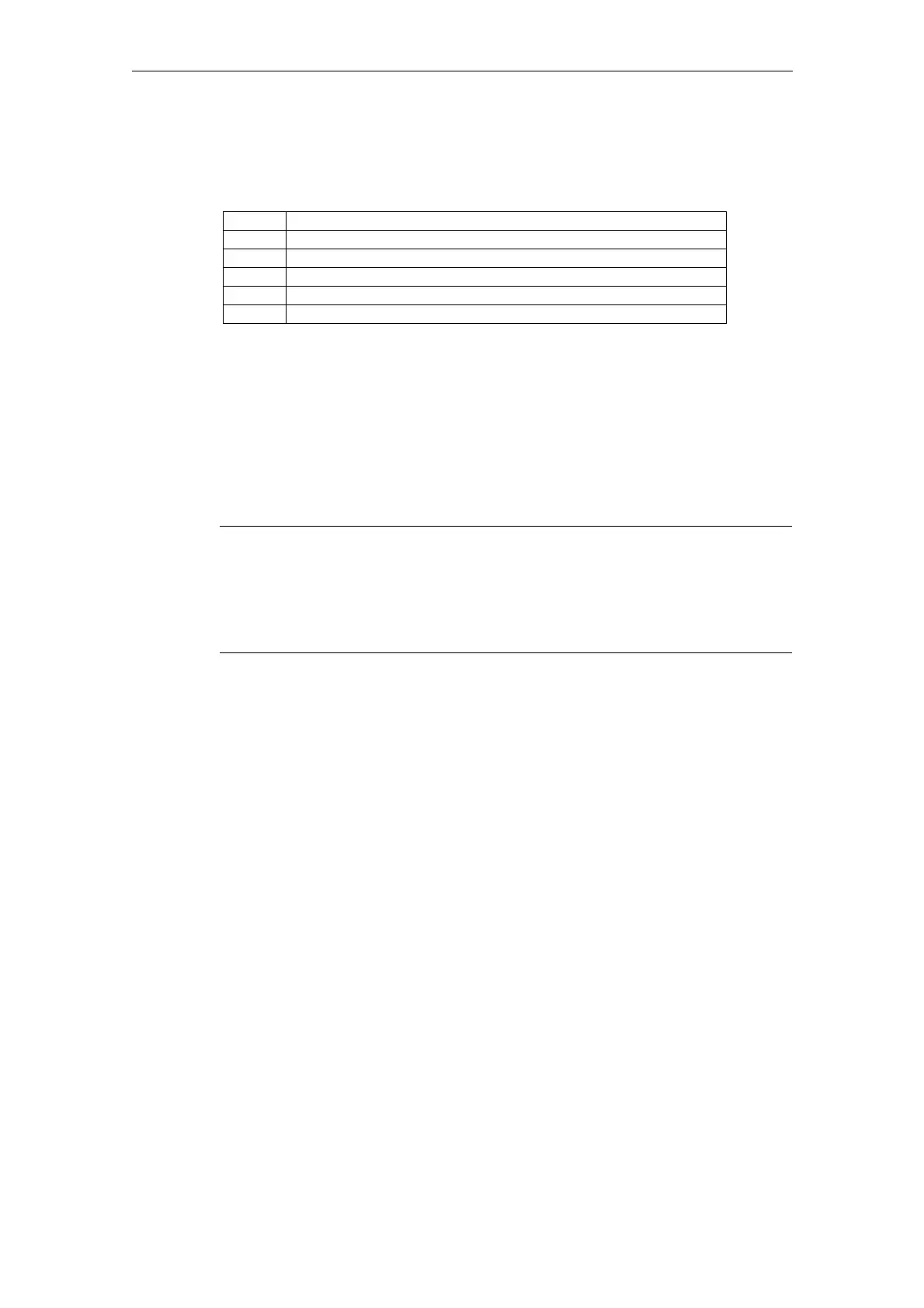

Error codes

The following error codes, which provide information to the HMI about errors during

the function request of the PLC, are stored in DB 19, DBB 36:

Value Meaning

0 No error

1 No function number (DBB32 bit 0-5)

2 Invalid parameter

3 Error when writing HMI-internal variable

10 Channel not present (DBB33)

Acknowledgment mechanism between HMI ↔ PLC

Via DB 19.DBB32 bits 6, 7, there is an acknowledgment mechanism that ensures

that the HMI and PLC agree on the channel selection:

• The PLC sets Bit 6 to 1 "Function request". The function request can only be set

by the PLC if bits 6 and 7 have the value “0”.

• After displaying the text in the header the HMI writes “0” again in Bbit 6 and the

interface is enabled for the PLC for the next action.

Note

If two HMI units are assigned to one NC/PLC unit (M:N), the PLC must first

determine from the control interface which of the HMI interfaces is active.

Channel/spindle displays can only be requested by the PLC for the active HMI

unit. The interface for selecting channel/spindle displays for the 2nd HMI unit is

located in DB19, DBB82-86. The use is the same as described for DBB32-36.

2.1.4 Block Search in Program Test Mode with Multiple Channels

Function

For this block search, the NC is operated in program test mode, so that interactions

between channel and synchronous actions and between multiple channels are

possible within an NCU.

During "Block search in program test mode", all auxiliary functions are output from

the NC to the PLC and the part program commands for channel coordination

(WAITE, WAITM, WAITMC, Replace axis, Write variables) are carried out by the

NC. That is:

• The PLC is updated during this block search

• Machining operations involving interaction among multiple channels are

executed properly within the block search.

Loading...

Loading...