Starting Up HMI Embedded (IM2) 08/2005

4 Functions/Parameterization

© Siemens AG, 2005. All rights reserved

IM2/4-58 SINUMERIK 840D sl/840D/840Di/810D HMI Installation and Start-Up Guide (IAM) – 08/2005 Edition

4.15 Coordinate systems

4.15.1 Actual value display

Via the display machine data MD 9424: MA_COORDINATE_SYSTEM you can set

whether

• the position of the workpiece coordinate system (programmed position,

corresponds to the default setting) or

• the holding position of the active tool relative to the workpiece zero must be

shown in the actual-value display.

MD 9424 = 0 Display in workpiece coordinate system, WCS

(default)

MD 9424 = 1 Display in settable zero system, SZS

(take-up position of active tool)

References: /FB1/K2: Axes, Coordinate Systems, Frames,…External Work

Offset

4.15.2 Position of coordinate system

The display machine data MD 9650: CMM_POS_COORDINATE_SYSTEM is used

to set the position of the coordinate system for milling.

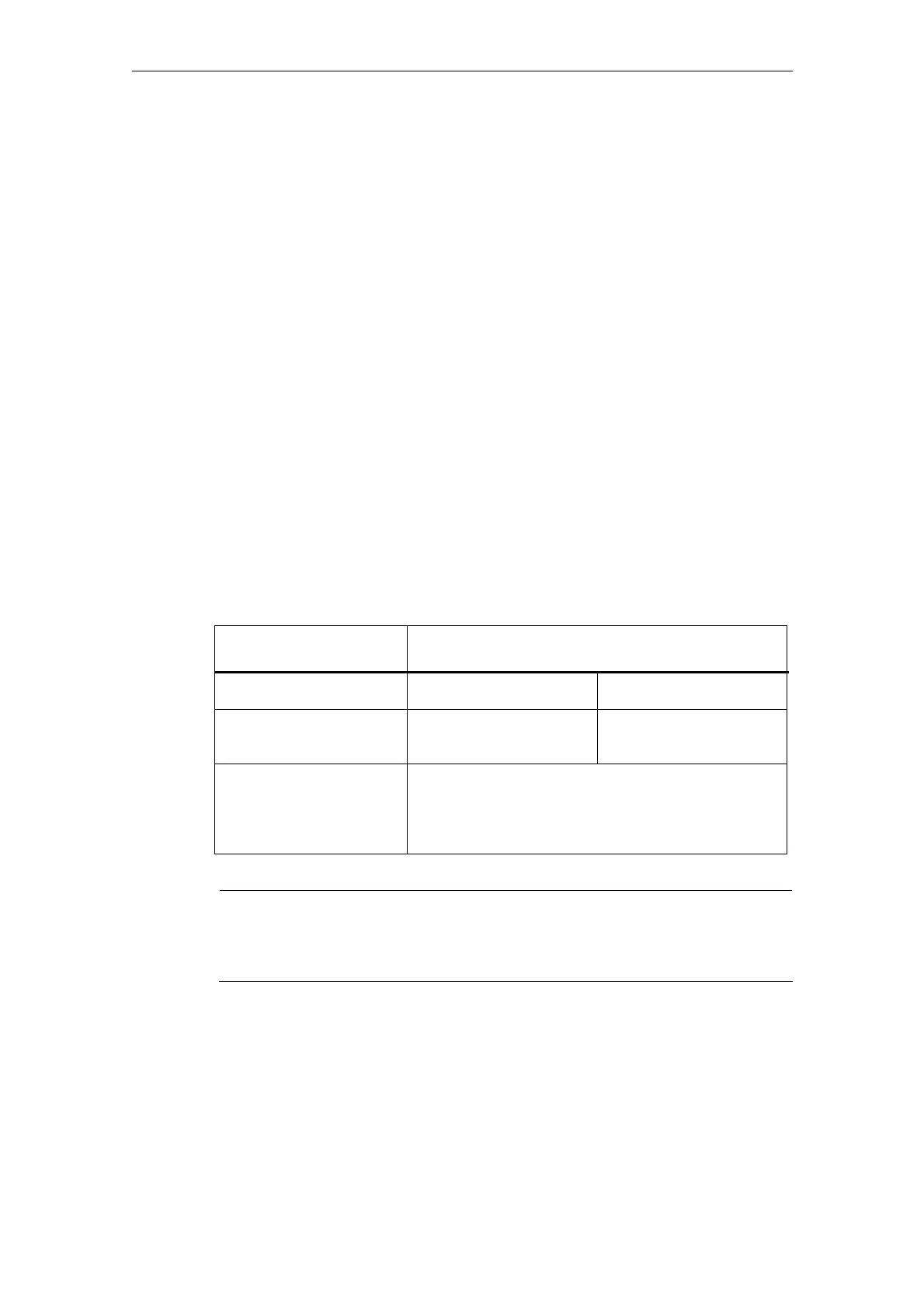

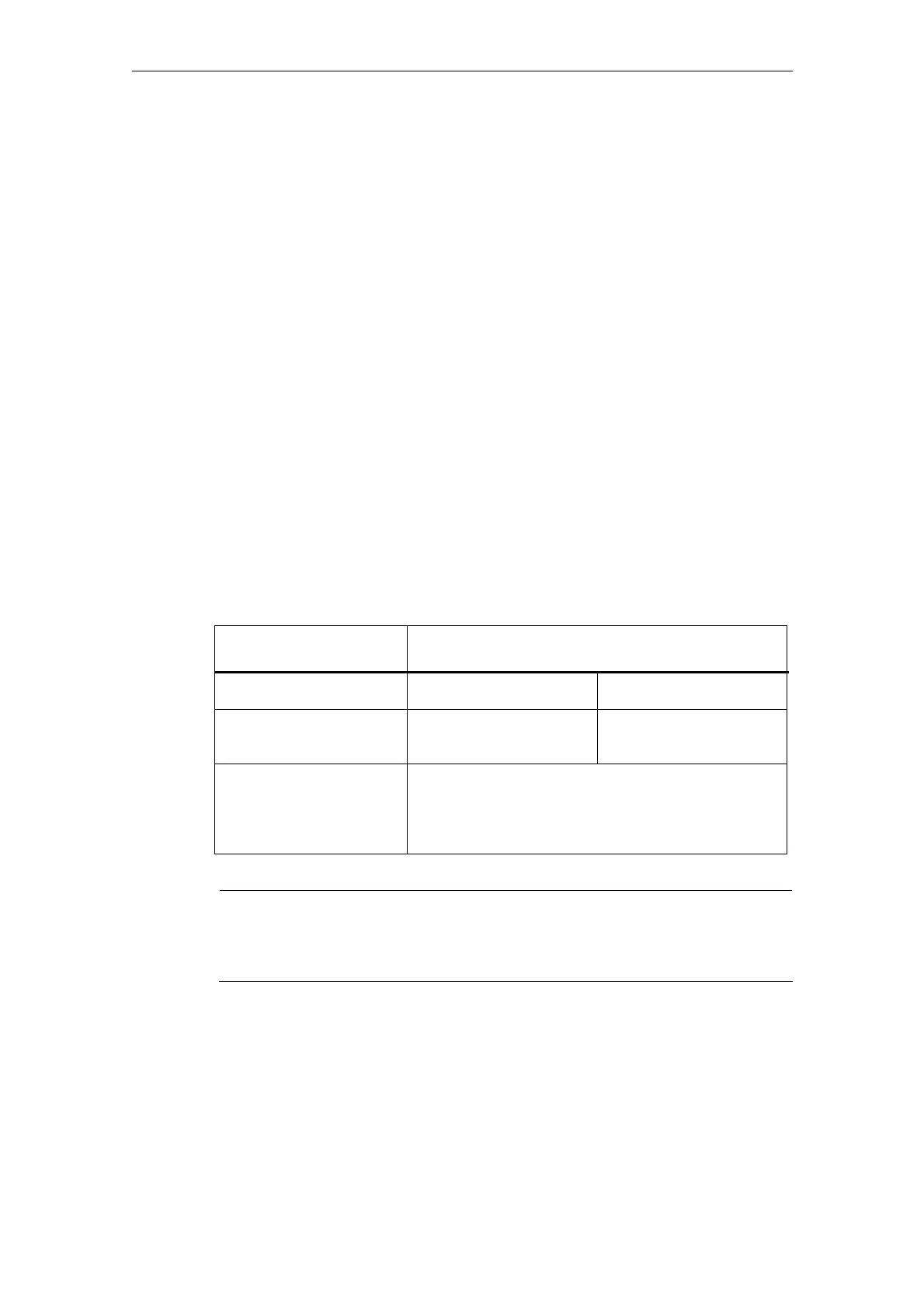

Table 4-3 Machine data 9650

9650 MD number

CMM_POS_COORDINATE_SYSTEM

Position of coordinate system

Default setting 0 Min. input limit: 0 Unit: -

Data type BYTE Valid as of SW release:

SW 05.01.13

Meaning With this machine data you adapt the coordinate

system of the user interface to the coordinate system

of the machine.

The coordinate system can assume the following

positions.

Note

The display machine data MD 9610: CTM_POS_COORDINATE_SYSTEM is

used to set the position of the coordinate system for milling.

References: /FB1/K1: Mode group, channel, program operation mode

Loading...

Loading...