08/2005 Expanding the Operator Interface (BE1)

8 Terms, Tables, Lists, Examples

© Siemens AG, 2005. All rights reserved

SINUMERIK 840D sl/840D/840Di/810D HMI Installation and Start-Up Guide (IAM) – 08/2005 Edition

BE1/8-195

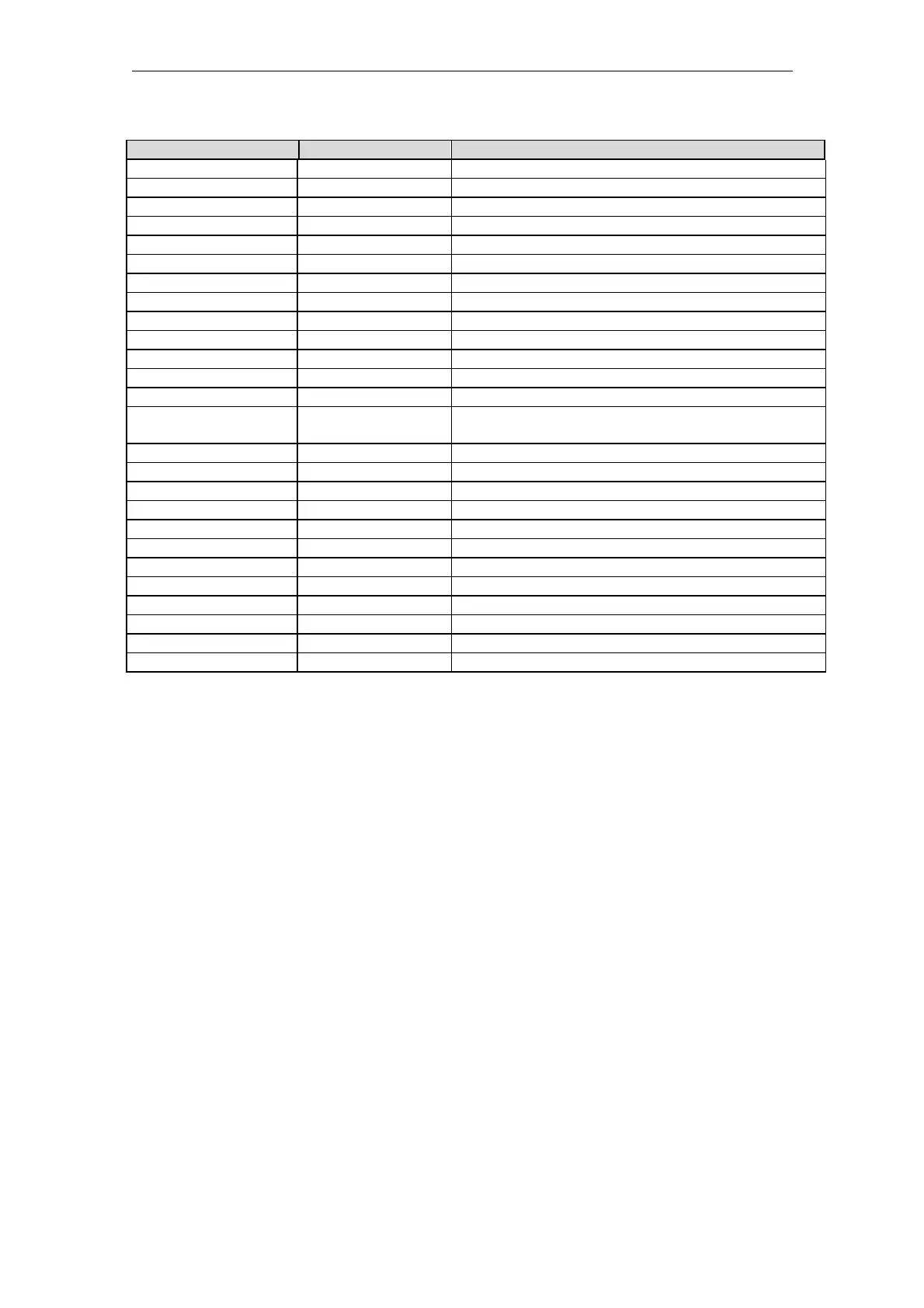

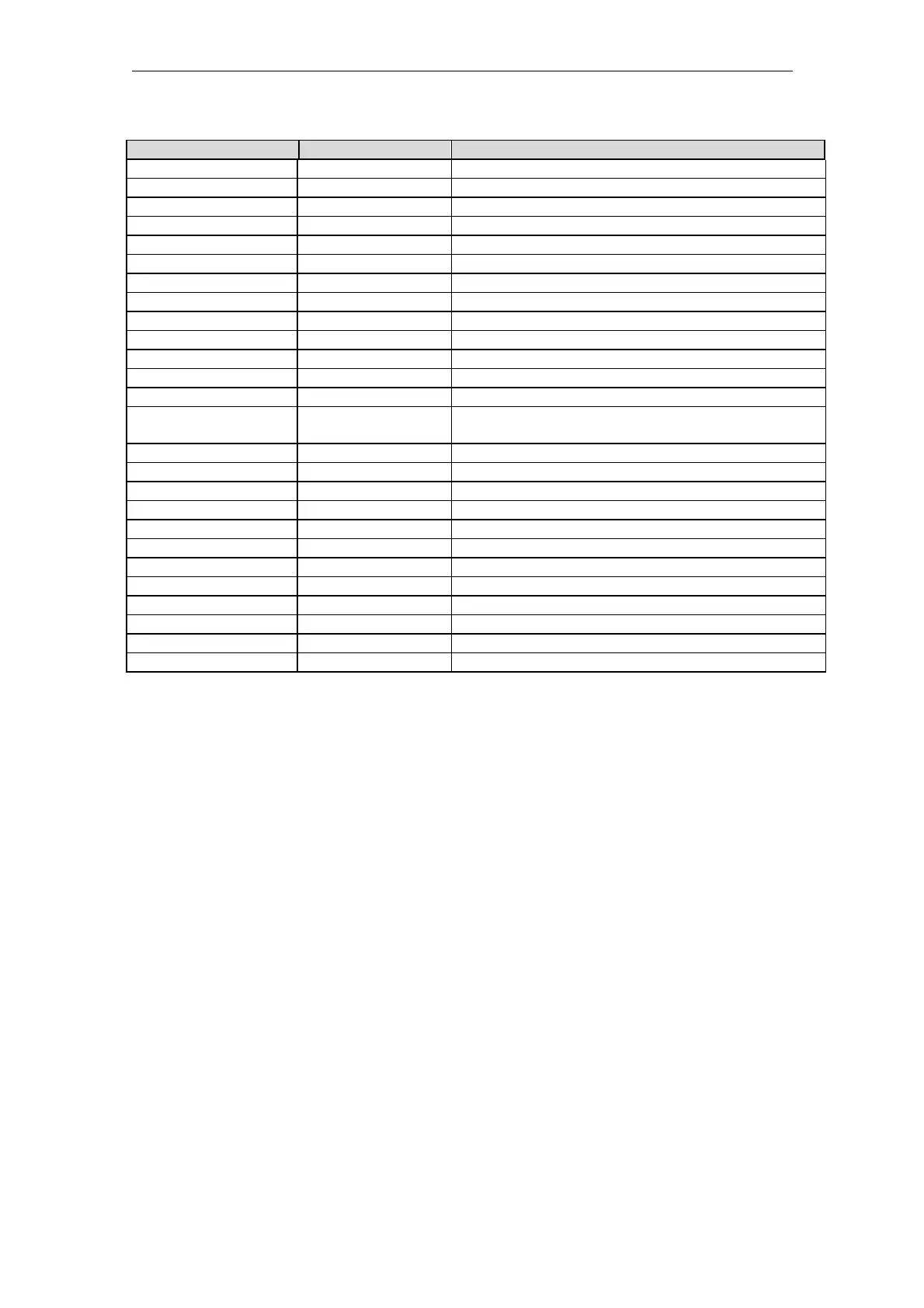

Name Index Description

$TC_SCP... Location-dependent wear correction

$TC_SCPx x=13,...21,....71 No. total offset pars. per total offset block

$TC_TP1 DUPLO number

$TC_TP10 Tool search type for replacement tools

$TC_TP11 Tool information for HMI

$TC_TP2 Tool designation

$TC_TP3 Size to left in half locations

$TC_TP4 Size to right in half locations

$TC_TP5 Size upwards in half locations

$TC_TP6 Size downwards in half locations

$TC_TP7 Magazine location type

$TC_TP8 Tool status

$TC_TP9 Tool monitoring method

$TC_TPCx[y] x=ParameterNo

y=ToolNo

User-defined tool parameter

$TC_TPG1 Spindle number

$TC_TPG2 Chaining rule

$TC_TPG3 Minimum wheel diameter

$TC_TPG4 Minimum grinding wheel width

$TC_TPG5 Current width of grinding wheel

$TC_TPG6 Maximum speed of grinding wheel

$TC_TPG7 Maximum grinding wheel peripheral speed

$TC_TPG8 Angle of inclination of inclined grinding wheel

$TC_TPG9 Compensation parameter for GWPS

$VA_COUP_OFFS[x] x=Axis Offset to leading axis / leading spindle, actual value

$VA_IS[x] x=Axis Safe actual position of axis

$VA_VACTM[x] x=Axis Actual-value, load-end axis velocity in MCS system

Loading...

Loading...