Section 04 TRANSMISSION

Sub-Section 05 (PULLEY DISTANCE AND ALIGNMENT)

04-05-4

Move the engine to obtain specified pulley align-

ment, torque engine support bolts to 55 N•m (41

lbf•ft) and remove engine support positioner.

Driven Pulley Movement

Shims can be mounted between chaincase and

frame. Use shim (P / N 504 0398 00), 0.53 mm

(.021 in) thick.

S-Series

TYPICAL

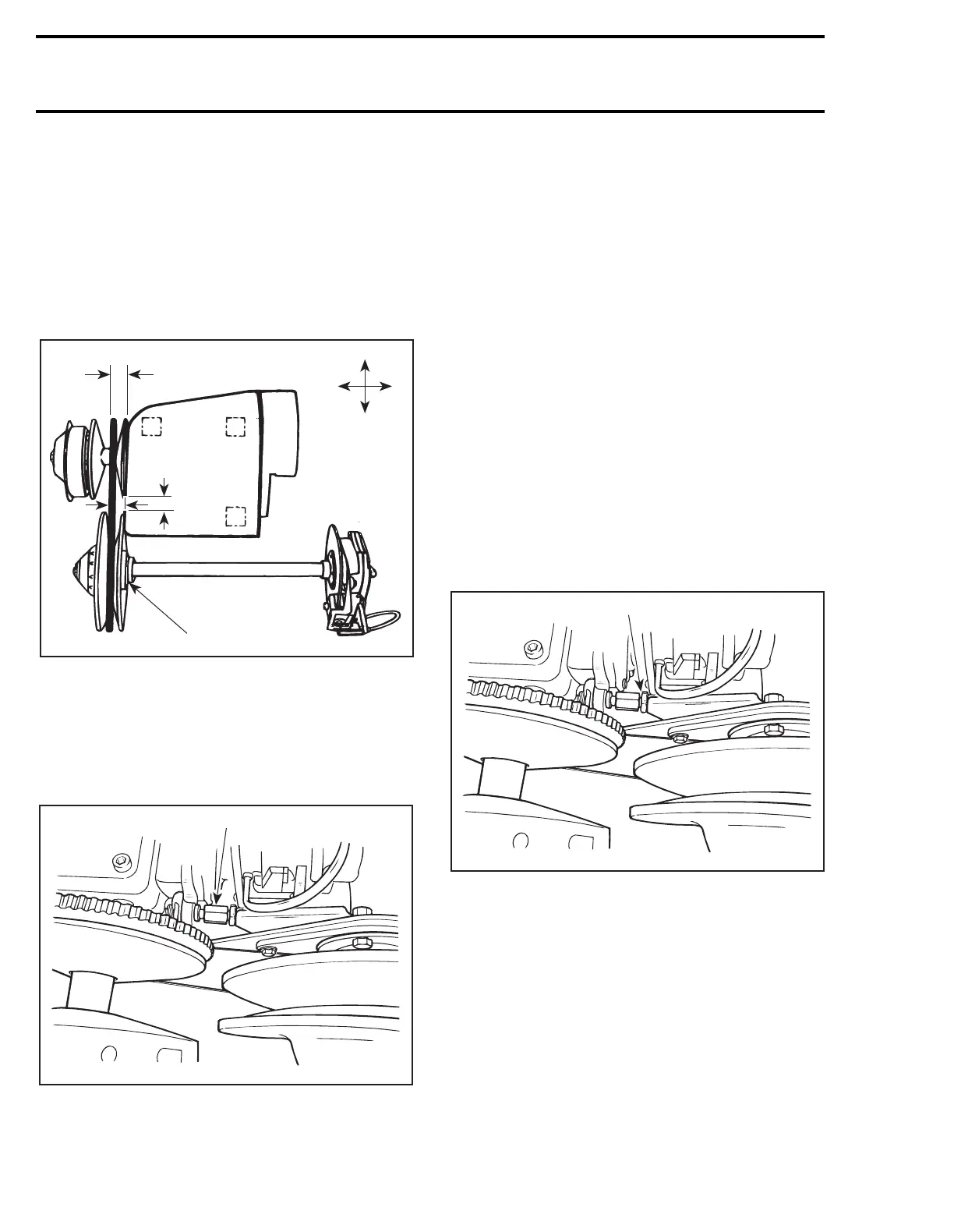

1. Engine movement

2. Contact

NOTE :

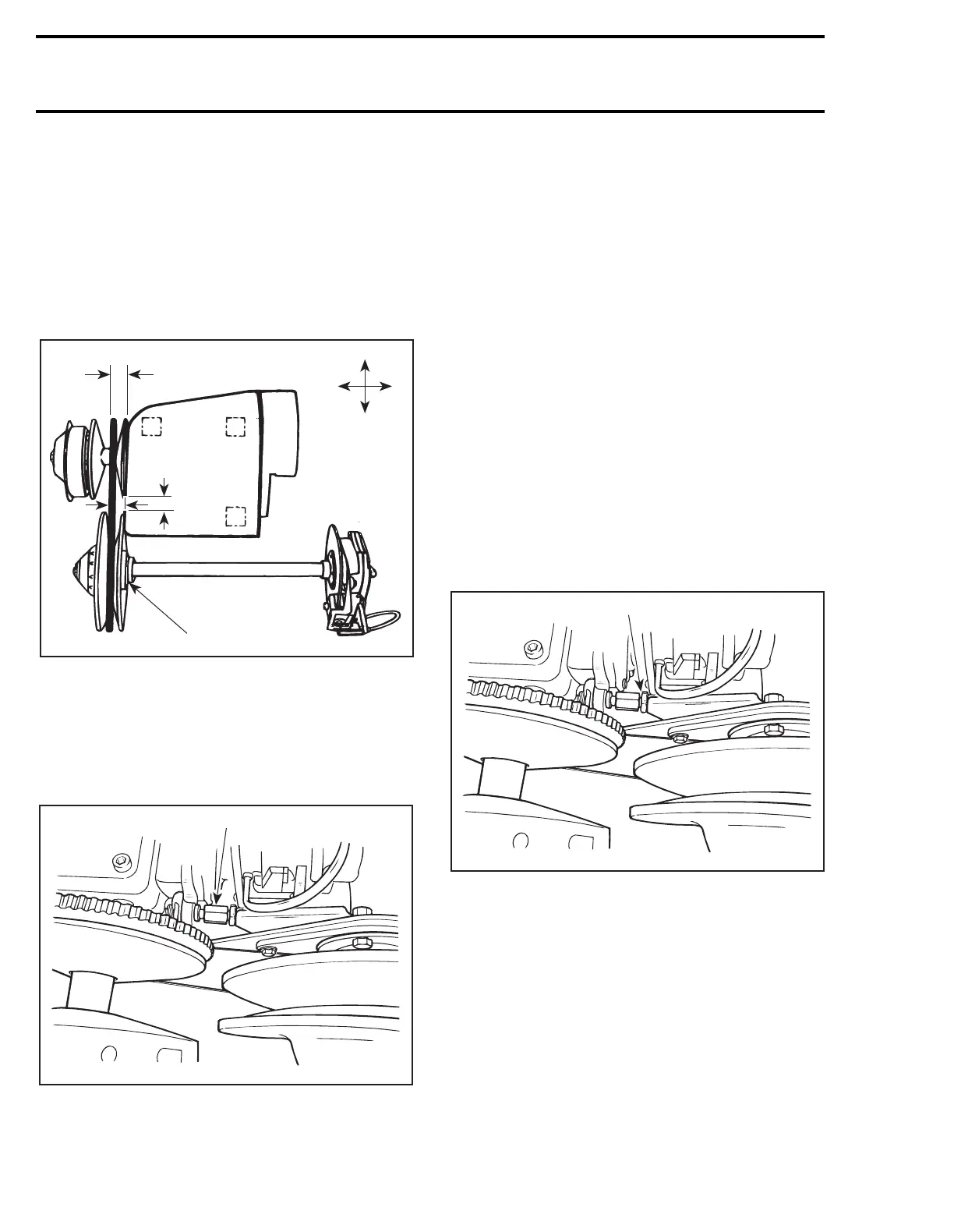

Prior to performing pulley adjust-

ment, loosen torque rod nut to allow engine

movement. Engine supports have tendency to

stick to frame, work engine loose prior to aligning.

1. Loosen

Pulley Distance Adjustment Method

Engine Movement

The engine support has slotted mounting holes.

Move engine to obtain specified distance be-

tween pulleys.

Pulley Alignment Method

Driven Pulley Movement

When engine slotted mounting holes do not allow

to set proper pulley offset X, adjust with shims

(P / N 504 1082 00) between pulley and counter-

shaft bearing support (pulley pushed toward

brake disc).

Engine Movement

Loosen the 4 bolts retaining engine support to the

frame. Position engine to obtain the specified

alignment.

NOTE :

After alignment, adjust torque rod

so it slightly contacts stopper plate. Do not

over tighten, it will disalign pulleys.

1. Retighten

1

A15D02A

Y

X

Z

2

A06D07B

1

'

A06D07A

1

Loading...

Loading...