Section 03 ENGINE

Sub-Section 02 (599, 699 AND 809 ENGINE TYPES)

03-02-11

ASSEMBLY

2,3, Crankshaft Bearing, Anti-seize

Lubricant and Labyrinth Sleeve

Smear anti-seize lubricant (P/N 413 7010 00) on

part of crankshaft where bearing fits.

Prior to installation, place bearings into an oil con-

tainer filled with oil previously heated to 75°C

(167°F). This will expand bearing and ease instal-

lation.

809 Engine Only

Last PTO bearing is 8 mm (5/16 in) from inner

bearing.

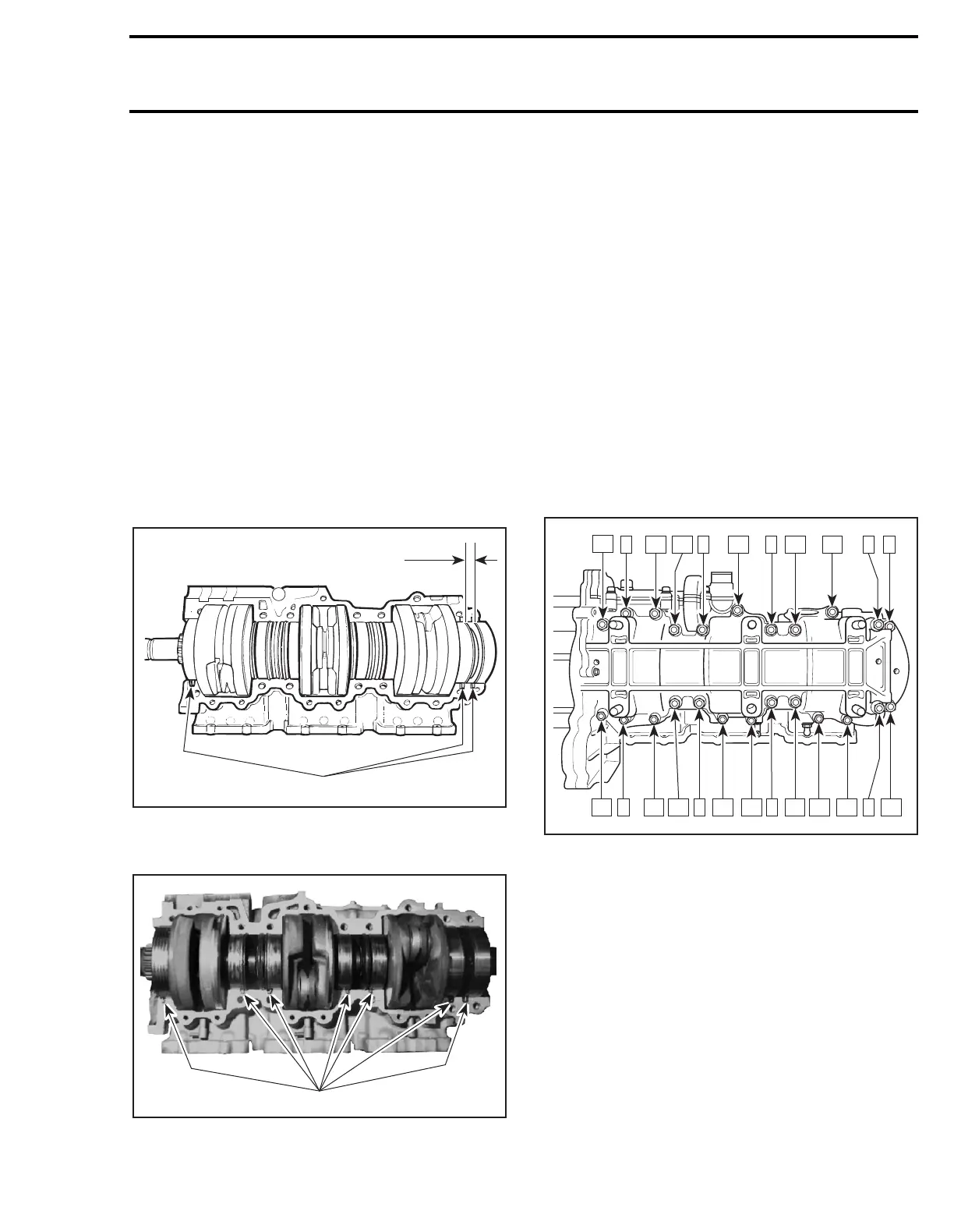

4, Crankcase

At crankshaft installation, position drive pins as il-

lustrated.

809 ENGINE

1. Drive pins

A. 8 mm (5/16 in)

599 AND 699 ENGINES

1. Drive pins

Crankcase halves

no. 4

and water pump housing

are factory matched and therefore, are not inter-

changeable as single halves.

Prior to joining of crankcase halves, spray some

new injection oil (or equivalent) on all moving

parts of the crankshaft. Spray Primer N (P/N 413

7081 00) on one of mating surfaces. Let it dry for

10 to 20 minutes.

Apply paste gasket (P/N 413 7027 00) on the other

mating surface.

NOTE:

Primer N allows Loctite 515 to fully cure

on aluminum surfaces. It increases filling capacity

and reduce curing time.

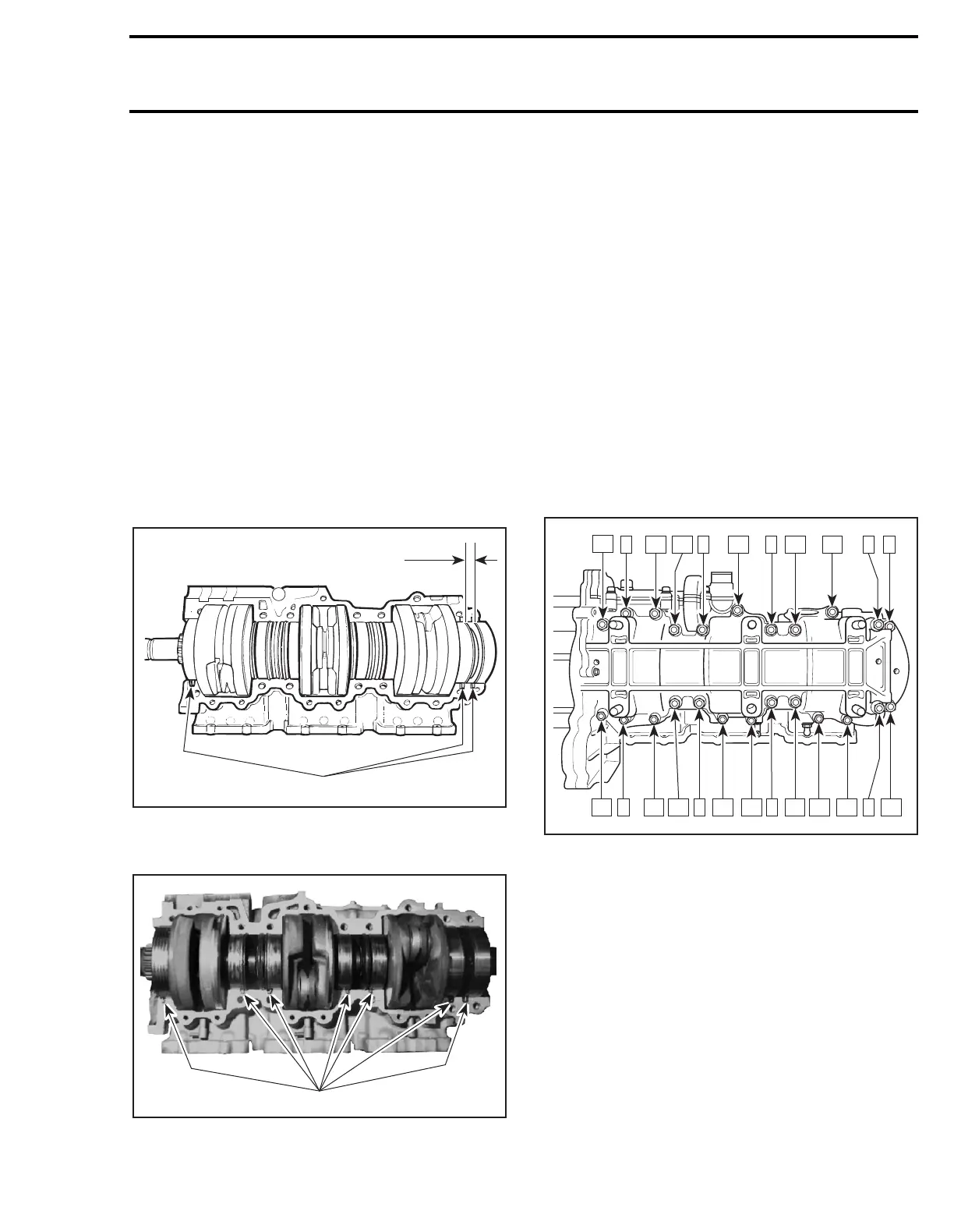

Torque crankcase screws in the following illustrat-

ed sequence. Tightening torques are:

M6 screws: 12 N•m (106 Ibf•

in

)

M8 screws: 30 N•m (22 Ibf•ft)

TYPICAL

5, Water Pump Housing

Apply silicone 732 RTV on sealing surface.

Tighten water pump housing screws to 10 N•m

(90 lbf•

in

) following sequence as illustrated.

A06C0HA

1

A

A06C22A

1

A06C3QA

23

6 20

17

1

15

4

13 11

8 9

7

10121416

2

1819

3

2122

5

24

Loading...

Loading...