Section 03 ENGINE

Sub-Section 03 (377, 443 AND 503 ENGINE TYPES)

03-03-6

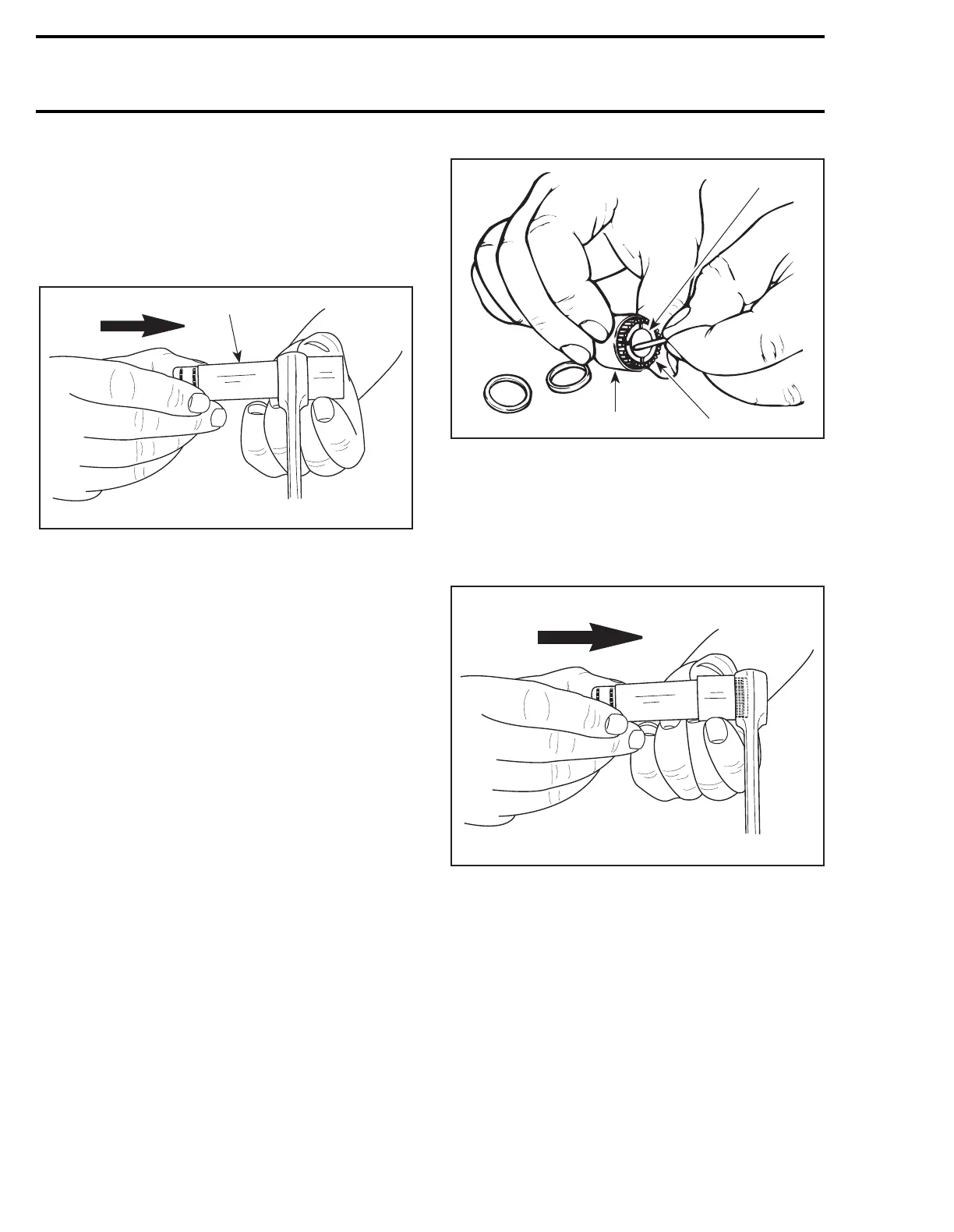

– Screw in puller in order to remove it from pis-

ton.

– Remove piston from connecting rod.

– Install locating sleeve. Then push needle bear-

ings along with thrust washers using a 21 mm

(.826 in) diameter pusher.

1. Pusher 21 mm (.826)

NOTE :

0.25 and 0.5 mm oversized piston

and rings are available if necessary.

Use a locking tie to fasten all needles and thrust

washers along with sleeves.

INSPECTION

Refer to ENGINE DIMENSIONS MEASUREMENT

03-04.

ASSEMBLY

503 Engine

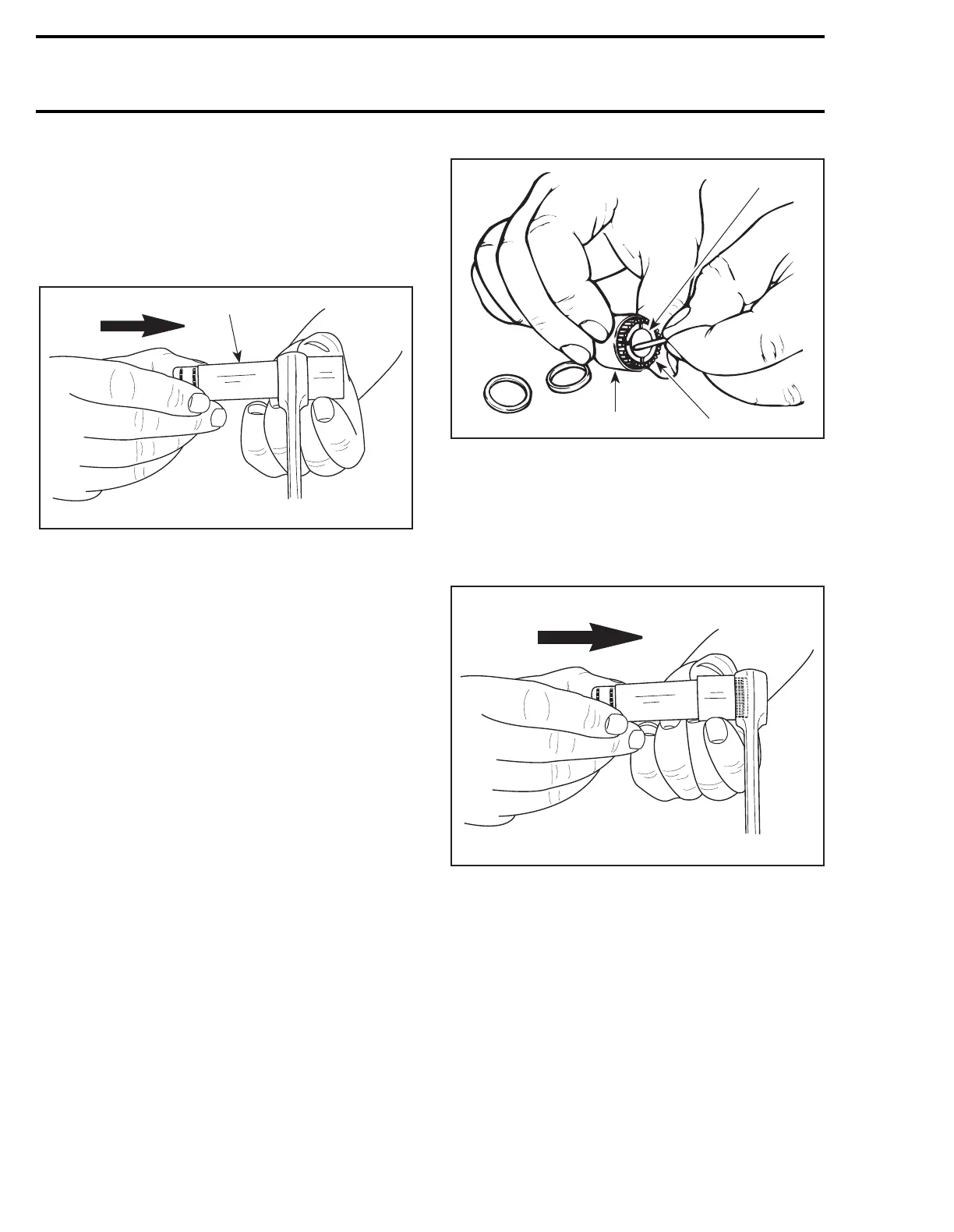

When reinstalling original needle bearings, make

sure that 31 needles are inserted between expan-

sion sleeve and locating sleeve.

1. Expansion sleeve

2. 31 needles

3. Locating sleeve

– Grease thrust washers and install them on each

end of needles.

– Using a 21 mm (.826 in) diameter pusher, insert

needles into connecting rod.

– Mount piston over connecting rod with the let-

ters “AUS” (over an arrow on the piston dome)

facing in the direction of exhaust port (see illus-

tration below).

– Install piston pin puller (P / N 529 0210 00) and

turn handle until piston pin is correctly posi-

tionned in piston.

A21C04A

1

'

A21C03A

1

23

A21C02A

Loading...

Loading...