PDW-700/V1 (E)

7-7

7-1-3. Replacing Cleaner Assembly

m

. The Cleaner assembly requires periodic check. Refer to “6-1. Periodic Check/Replacement Parts List”

for details.

. To prevent the possibility of damage to the optical block assembly in the drive assembly by static

electricity charged in a human body or clothes, be sure to establish a ground before starting the service

operation. (Refer to Section 1-12-1.)

. The spindle motor and the actuator around the objective lens have intense magnetic circuits. Keep

magnetic substance away from these parts. If the magnetic force makes a screwdriver hit the actuator,

the objective lens will be damaged. If the magnetic substance is moved close to these parts, their

characteristics may be changed.

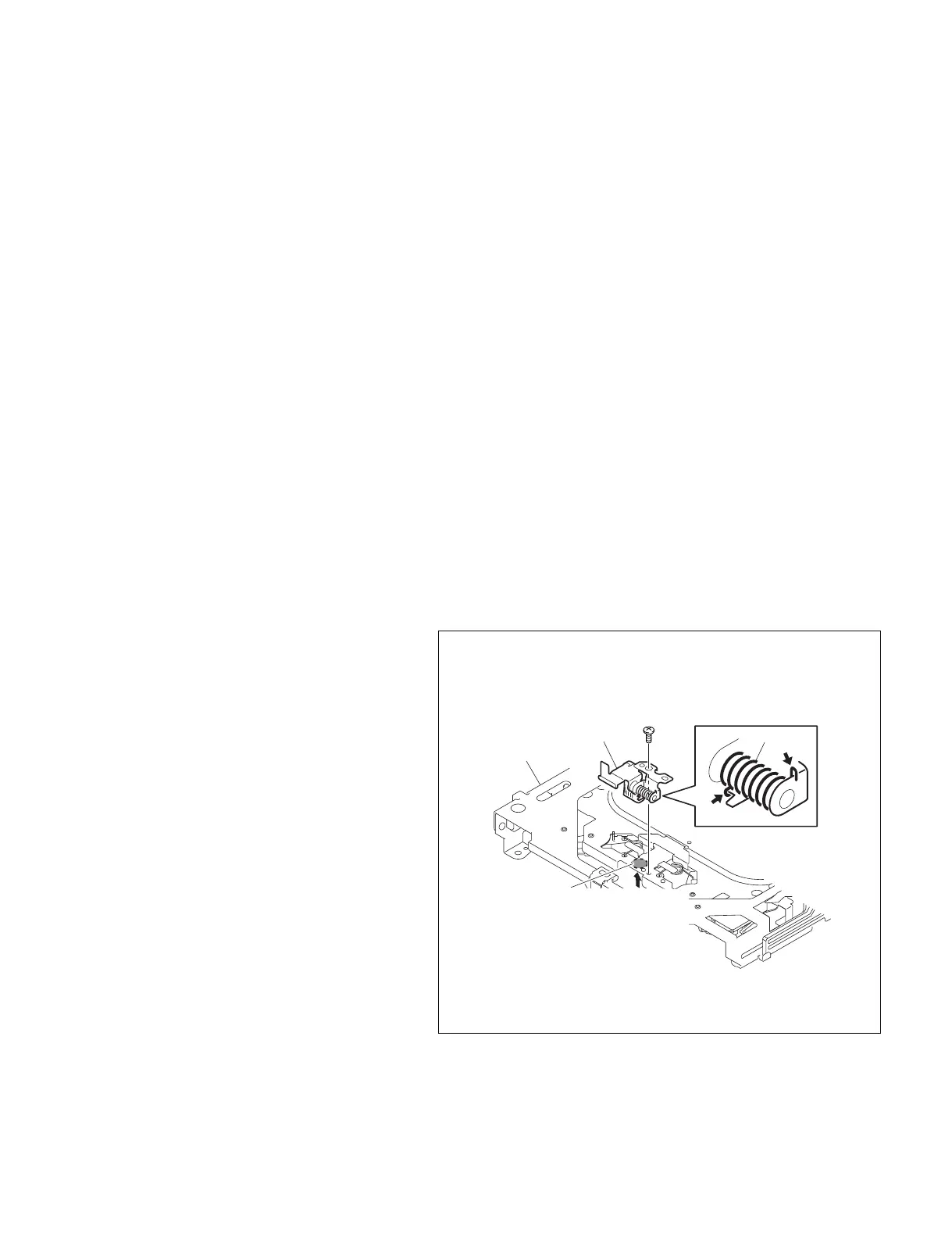

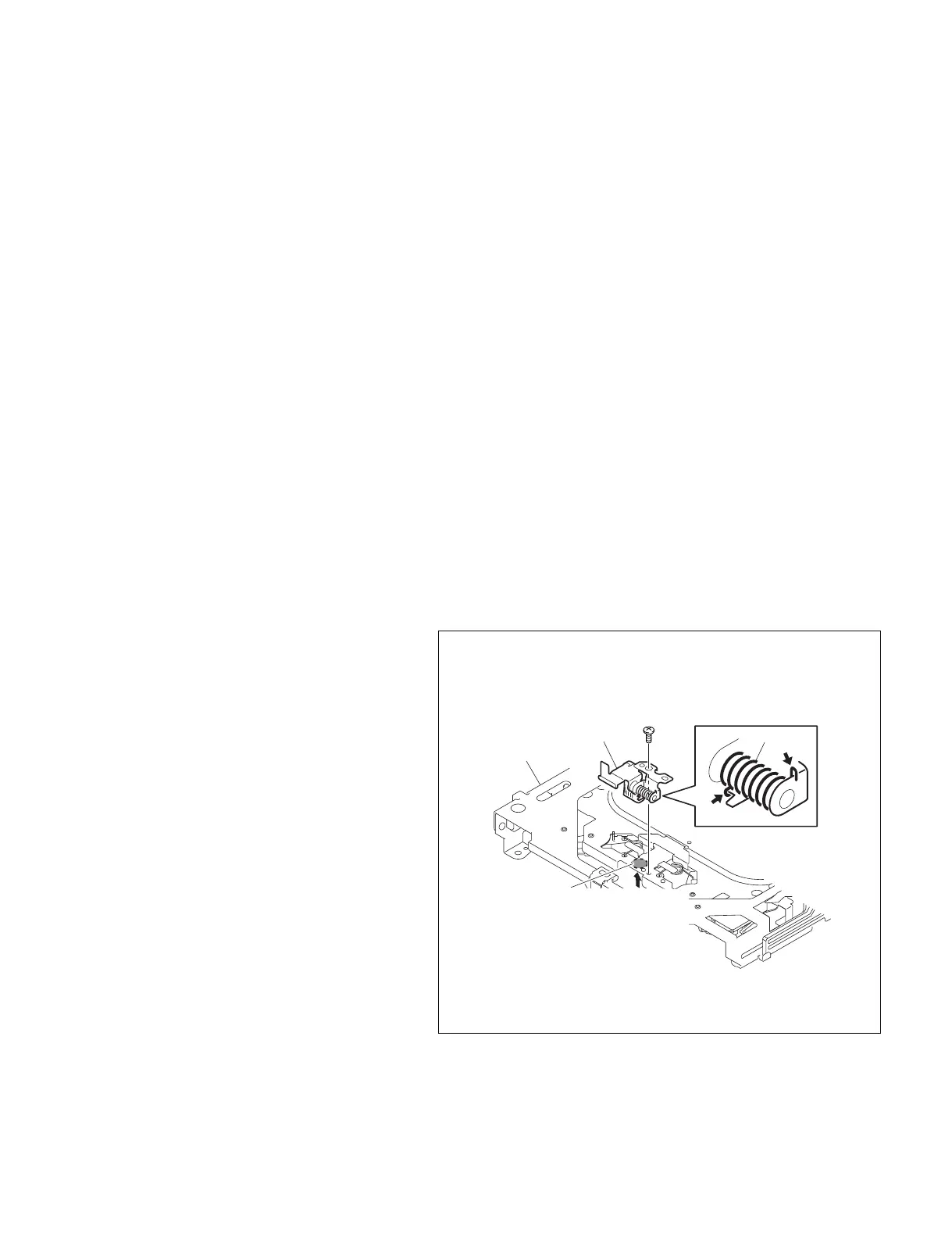

Loader assembly

Cleaner assembly

CL spring

A

Special screw

2 x 2

Support this part

from the back side

with fingers.

1. Remove the outside panel assembly.

(Refer to Section 1-7-1.)

2. Remove the laser caution sheet.

(Refer to Section 1-6-2 step 2.)

3. Remove the corner block with adhesive sheet

and cover sheet.

(Refer to Section 7-1-1 step 3.)

4. Remove the SW guard assembly.

(Refer to Section 1-7-6.)

5. Remove the loader assembly.

(Refer to Section 7-1-1.)

6. Remove the screw, and remove the cleaner

assembly.

m

. Be careful not to deform the loader assem-

bly.

. Take care so that the CL spring does not

come off.

7. While pressing portion A on the back of the

loader assembly with fingers, remove the

screw to remove the cleaner assembly.

m

. When installing, take care so that the CL

spring does not come off.

. When tightening the screw, support the

loader assembly with fingers not to deform

it.

8. Reinstall the removed parts by reversing

steps 1 to 5.

Loading...

Loading...