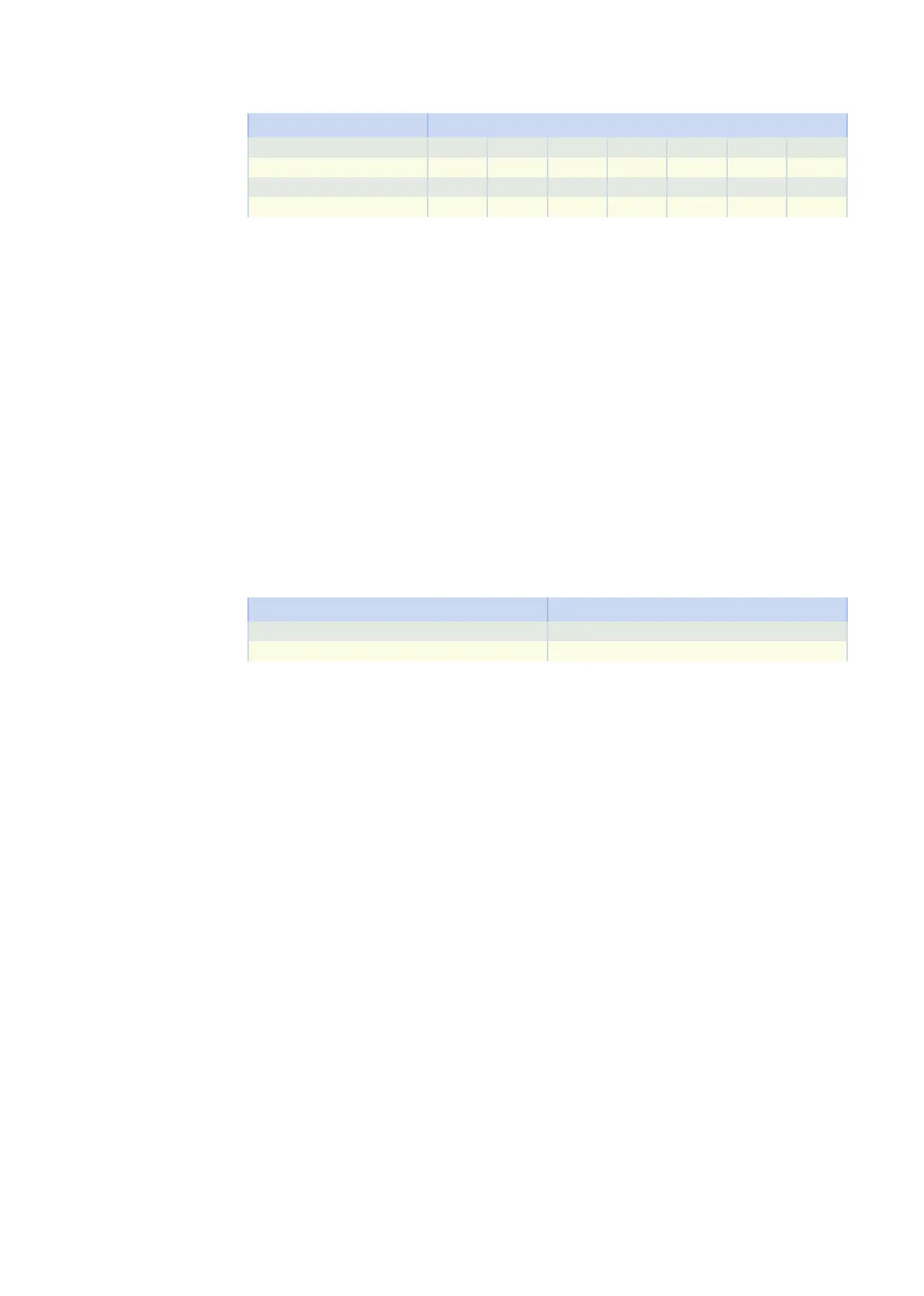

10.5.4 Combinatorial shaft/housing design

Housing design

Shaft design Code G F NG NF GD NGD

Hollow shaft with keyway A AG AF ANG ANF AGD ANGD

Hollow shaft with shrink ring S SG SF SNG SNF SGD SNGD

Solid shaft

1)

V VG VF VNG VNF − −

1)

Gear units in sizes K1 – K10 come with a solid shaft with feather key as standard. Gear units in sizes K1 –

K4 can be ordered with the option of a solid shaft without feather key. Only upon request starting at size K5.

10.5.5 Installation conditions

Hollow shaft

The hollow shaft hole tolerance is ISO H7. The tolerance of the machine shaft must be ISO k6.

Take care to align the machine shaft with the gear unit hollow shaft when attaching the gear unit.

Maximum deviation ≤ 0.03 mm.

For simpler assembly and disassembly of the machine shaft, the hollow shafts are equipped with a spiral

groove (as a grease deposit).

A hardened, threaded keeper plate is included in the scope of delivery. You also have the option to order

the hollow shaft without a keeper plate.

Hollow shaft with shrink ring

The tolerance of the hollow shaft hole is ISO H7.

The machine shaft must be executed as follows:

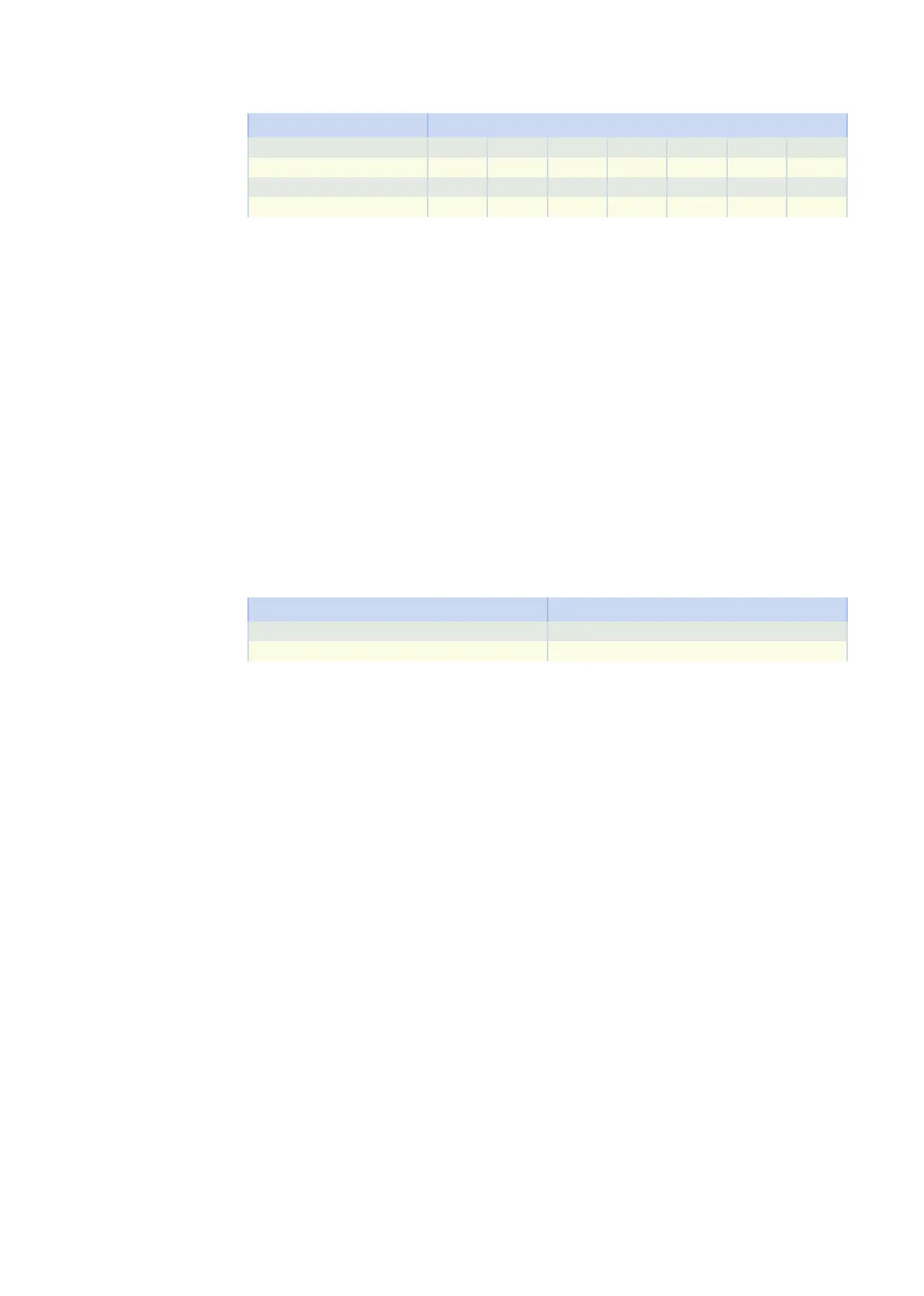

Gear unit type Tolerance

K1 to K6 ISO h9

K7 to K10 ISO h6

Select a material for the machine shaft with a permitted surface pressure of p ≥ 325 N/mm

2

.

Possible materials:

• C45E +QT

• 42CrMo4

Fastening the gear units on the machine side using the pitch circle diameter

The specified torques and forces only apply when gear units are fastened on the machine side using screws

of strength class 10.9. In addition, the gear housings must be adjusted at the pilot. The machine-side fit

must be H7.

10.5.6 Mounting positions

The following table shows the standard mounting positions.

The numbers identify the gear unit sides. The mounting position is defined by the gear side facing down-

wards.

10 Khelical bevel geared motors 10.5 Product description

359

Loading...

Loading...